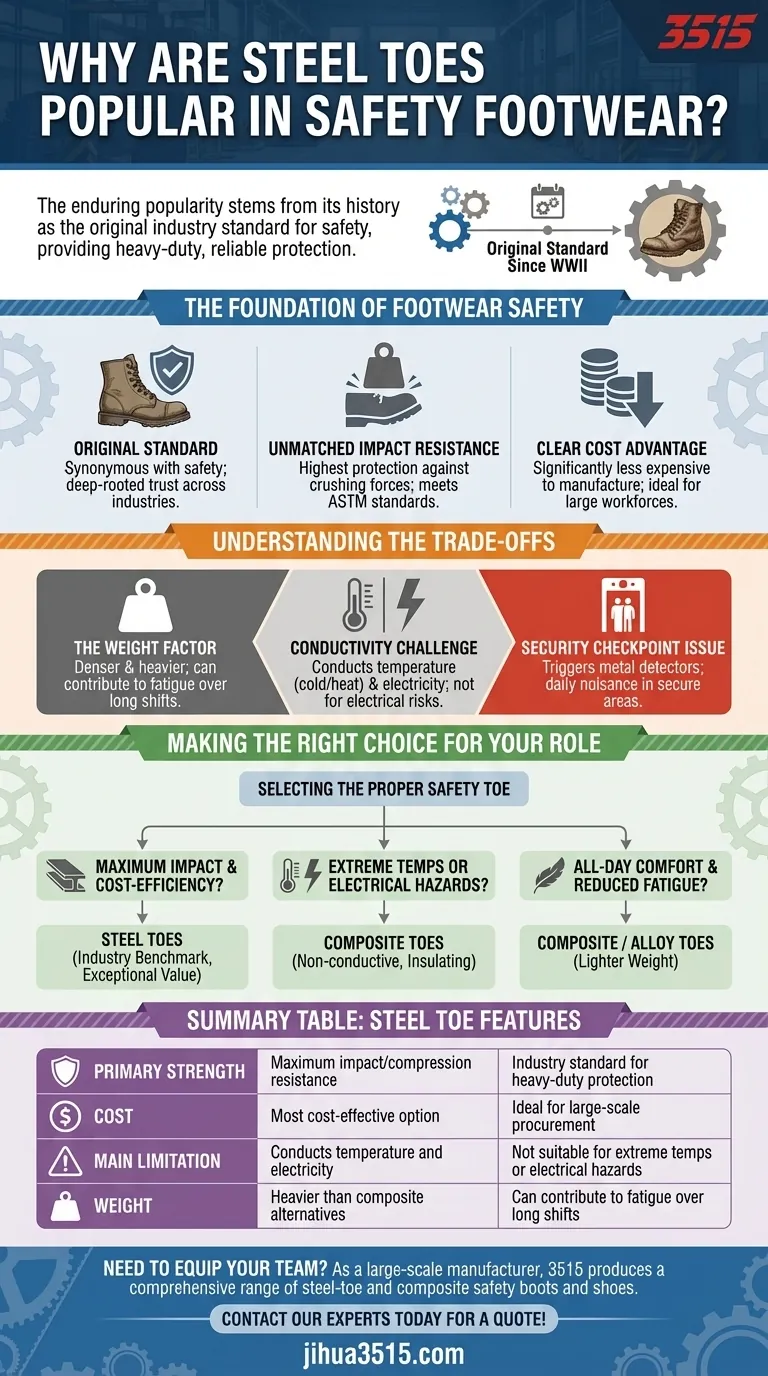

The enduring popularity of steel-toed footwear stems from its long history as the original industry standard for safety. It is the most common and cost-effective option for providing heavy-duty, reliable protection against impact and compression, making it a foundational choice for worker safety since its widespread adoption after World War II.

While steel toes offer exceptional strength and value, they are not the only solution. The "best" protective toe material is ultimately determined by the specific hazards and environmental conditions of your workplace, including factors like weight, temperature, and electrical risk.

The Foundation of Footwear Safety

Steel was the original material used for reinforcing the toes of work boots, establishing the benchmark for performance and safety standards that all other materials are measured against. Its prevalence is rooted in a few key, undeniable strengths.

The Original Standard for Protection

For decades, steel was the only option, making it synonymous with safety footwear. This legacy has created deep-rooted trust and widespread acceptance across nearly every industrial sector. When a job site requires "safety toes," steel is the default expectation.

Unmatched Impact Resistance

The primary function of a safety toe is to protect against crushing forces. Steel offers the highest level of resistance to impact and compression, providing robust, heavy-duty protection that meets or exceeds all relevant safety standards, such as those from ASTM International.

A Clear Cost Advantage

Compared to modern alternatives like composite materials, steel is significantly less expensive to manufacture. This cost-effectiveness makes it an extremely popular choice, especially for companies outfitting large workforces where budget is a primary consideration.

Understanding the Trade-offs of Steel

While steel is an excellent and reliable choice, its physical properties create specific disadvantages. Acknowledging these trade-offs is critical for making an informed decision about your personal protective equipment.

The Weight Factor

Steel is denser and heavier than composite or alloy alternatives. While a minor difference for a single boot, this added weight can contribute to foot fatigue and reduced comfort over the course of a long workday.

The Conductivity Challenge

As a metal, steel readily conducts temperature. In cold environments, steel-toed boots can become uncomfortably cold, while in extreme heat, they can retain warmth. More importantly, because steel conducts electricity, it is not suitable for certain jobs where contact with live electrical circuits is a risk.

The Security Checkpoint Issue

A minor but practical inconvenience is that steel toes will consistently trigger metal detectors. For professionals who must frequently pass through security checkpoints, such as in airports or secure facilities, this can be a daily nuisance.

Making the Right Choice for Your Role

Selecting the proper safety toe is a matter of matching the material's properties to the demands of your job.

- If your primary focus is maximum impact protection and cost-efficiency: Steel toes remain the undisputed industry benchmark and provide exceptional value.

- If you work in extreme temperatures or near electrical hazards: Non-metallic composite toes are the superior choice for their insulating and non-conductive properties.

- If your priority is all-day comfort and reduced fatigue: Lighter composite or alloy toes will provide a noticeable benefit over long and active shifts.

Understanding these core differences empowers you to select safety footwear based on your specific risks and daily demands.

Summary Table:

| Feature | Steel Toe | Key Consideration |

|---|---|---|

| Primary Strength | Maximum impact/compression resistance | Industry standard for heavy-duty protection |

| Cost | Most cost-effective option | Ideal for large-scale procurement |

| Main Limitation | Conducts temperature and electricity | Not suitable for extreme temps or electrical hazards |

| Weight | Heavier than composite alternatives | Can contribute to fatigue over long shifts |

Need to equip your team with reliable, high-performance safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel-toe and composite safety boots and shoes for distributors, brand owners, and bulk clients. We offer the right protective solution tailored to your specific workplace hazards, workforce size, and budget.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- How do safety boots provide toe protection? A Guide to Steel vs. Composite Caps

- What are key tips for fitting steel toe boots correctly? Ensure Safety and All-Day Comfort

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- What are the characteristics of a properly fitting steel toe boot? Achieve All-Day Safety and Comfort

- What industries are steel toe boots commonly used in? Essential Foot Protection for High-Risk Work

- What are the advantages of steel toe protection in work boots? Unmatched Safety & Durability

- How do steel toe boots compare to composite toe boots in terms of protection? A Guide to Maximum Safety & Comfort