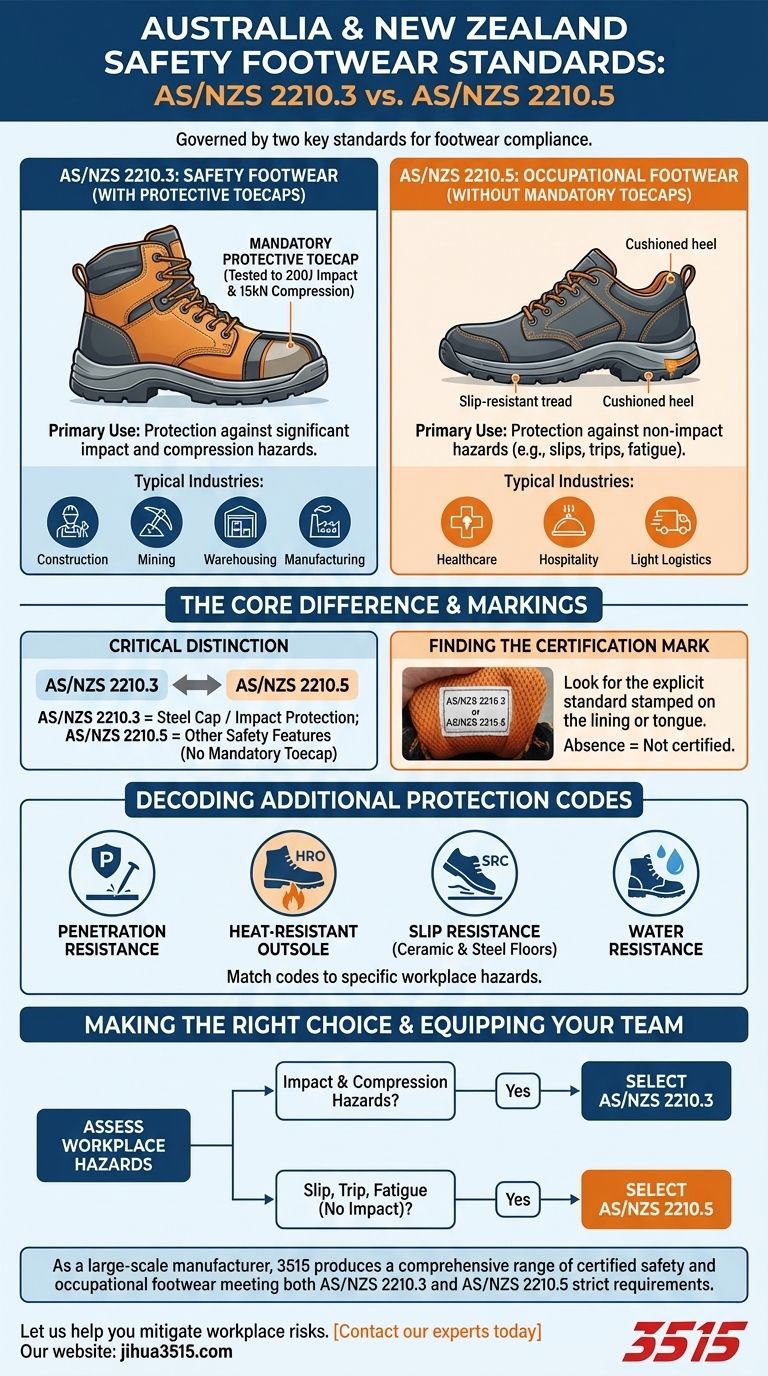

In Australia and New Zealand, safety footwear compliance is governed by two key standards. These are AS/NZS 2210.3, which covers true safety footwear with protective toecaps, and AS/NZS 2210.5, which applies to occupational footwear that may have other safety features but lacks the mandatory protective toecap.

The critical distinction is that AS/NZS 2210.3 is the standard for boots with toecaps designed to protect against impact, like traditional steel caps. AS/NZS 2210.5 is for work boots where the primary hazards are not impact-related, such as slips or static electricity.

The Core Difference: Safety vs. Occupational Footwear

Understanding the purpose behind each standard is crucial for ensuring proper Personal Protective Equipment (PPE) selection. They are not interchangeable and address fundamentally different workplace risks.

AS/NZS 2210.3: The Standard for Safety Footwear

This is the primary standard for any footwear marketed as a "safety boot," including steel, composite, or alloy cap boots.

Its main requirement is the presence of a protective toecap tested to withstand a 200-joule impact and a 15-kilonewton compression force.

This standard is essential for roles in construction, mining, manufacturing, warehousing, and any environment where there is a significant risk of objects falling on or crushing the foot.

AS/NZS 2210.5: The Standard for Occupational Footwear

This standard applies to footwear designed for professional use that may have protective features but does not include the mandatory 200-joule toecap.

Safety features under this standard can include slip resistance, penetration resistance, antistatic properties, or energy absorption around the heel.

It is intended for workplaces like healthcare, hospitality, and light-duty logistics where the primary risks are slips, trips, and long-term fatigue, rather than heavy impacts.

Understanding the Trade-offs and Markings

Simply knowing the standard number is not enough. You must be able to identify compliant footwear and understand its specific protections to avoid making a critical safety error.

Finding the Certification Mark

A compliant boot must have the standard it conforms to stamped or stitched into its lining, typically on the tongue.

Look for the explicit text AS/NZS 2210.3 or AS/NZS 2210.5. The absence of this mark is a clear indicator that the footwear is not certified for workplace use in Australia or New Zealand.

Decoding Additional Protection Codes

Beyond the main standard, boots are often marked with codes that identify their specific protective qualities. This allows you to match the boot to the exact hazards of your job.

Common codes include:

- P: Penetration resistance for the sole

- HRO: Heat-resistant outsole

- SRC: Slip resistance on both ceramic tile and steel floors

- WR: Water resistance

The Pitfall of "Work Boots"

A common mistake is assuming any sturdy-looking "work boot" is a "safety boot."

If a boot is only certified to AS/NZS 2210.5, it offers no certified protection against impact, even if it looks tough. For protection against falling objects, certification to AS/NZS 2210.3 is non-negotiable.

Making the Right Choice for Your Goal

Use this framework to select the correct footwear based on a clear assessment of your workplace hazards.

- If your primary focus is protection from impact and compression hazards (e.g., construction, warehouse): You must select boots explicitly certified to AS/NZS 2210.3.

- If your primary focus is slip resistance and comfort without impact risk (e.g., hospitality, healthcare): Footwear certified to AS/NZS 2210.5 is the appropriate choice.

- If you face multiple hazards like sharp objects, water, or heat: Ensure you check for additional protection codes (like P, WR, or HRO) beyond the basic standard certification.

Properly interpreting these standards transforms footwear selection from a guess into a critical part of your safety strategy.

Summary Table:

| Standard | Primary Use | Key Requirement | Typical Industries |

|---|---|---|---|

| AS/NZS 2210.3 | Safety Footwear | Mandatory protective toecap (200J impact) | Construction, Mining, Warehousing |

| AS/NZS 2210.5 | Occupational Footwear | No mandatory toecap; other safety features | Healthcare, Hospitality, Light Logistics |

Ensure Your Team is Equipped with the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety and occupational footwear for distributors, brand owners, and bulk clients. We ensure every pair meets the strict requirements of AS/NZS 2210.3 and AS/NZS 2210.5, providing the precise protection your workforce needs.

Let us help you mitigate workplace risks. Contact our experts today to discuss your requirements and explore our full product catalog.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- How can comfort be improved when wearing steel toe boots? A Guide to Pain-Free Workdays

- Are steel toe shoes unsafe for electricians? Debunking the EH-Rated Footwear Myth

- What industries commonly require the use of steel cap work boots? Essential Guide for High-Risk Sectors

- What is the primary function of Martensitic 1200 grade steel in UHSS toe caps? Achieve Slim, Lightweight Protection

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- What are the advantages of steel toe boots? Maximum Protection, Lower Cost & Streamlined Design

- What are the benefits of steel toe caps in work boots? Achieve Maximum Protection for Heavy-Duty Work