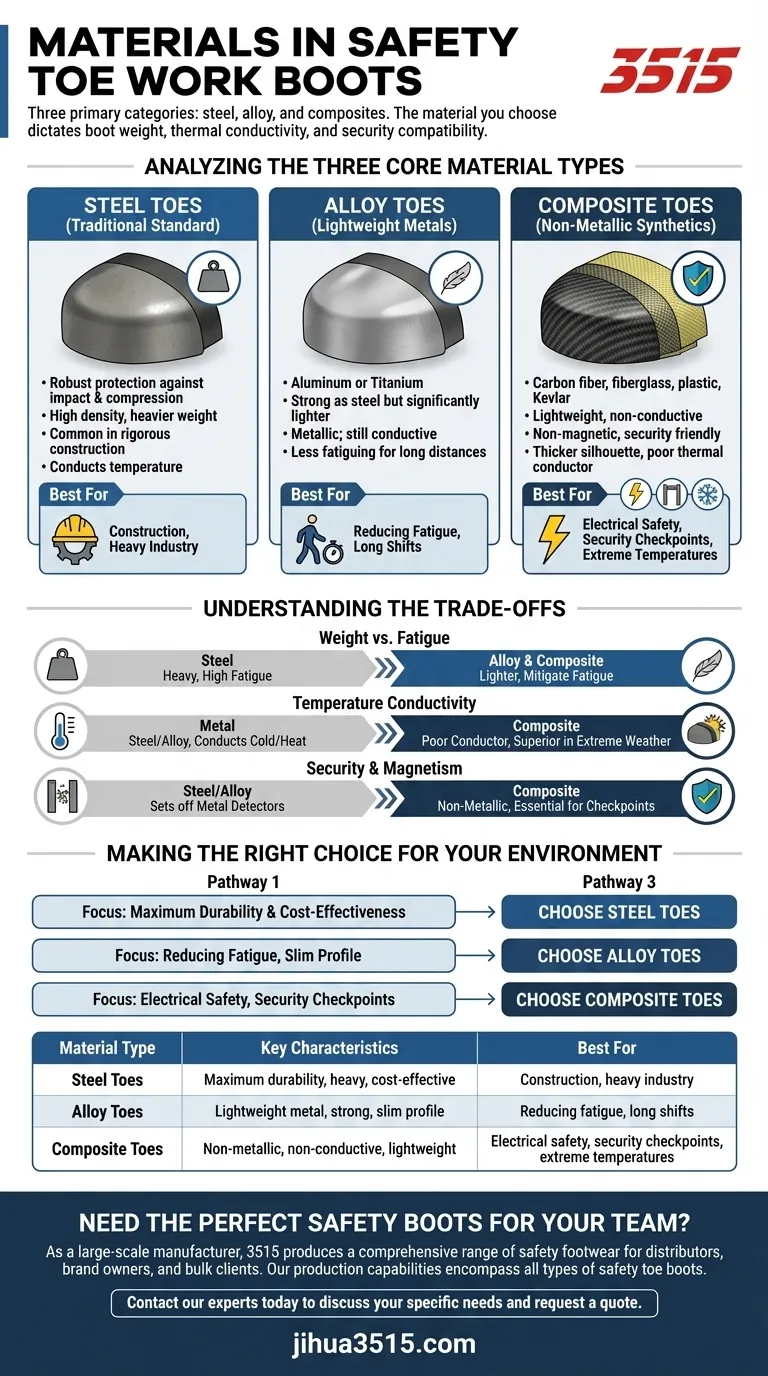

The three primary categories of materials used in the toe portion of safety work boots are steel, alloy metals, and composites. Steel offers traditional, heavy-duty protection; alloys (such as aluminum or titanium) provide similar strength with less weight; and composites utilize non-metallic synthetics like carbon fiber, plastic, fiberglass, or Kevlar to offer lightweight, non-conductive safety.

While steel, alloy, and composite toes are all engineered to meet safety standards for impact and compression, the material you choose directly dictates the boot's total weight, thermal conductivity, and compatibility with security checkpoints.

Analyzing the Three Core Material Types

Steel Toes (The Traditional Standard)

Steel remains the most common material for safety toes due to its proven track record. It offers robust protection against heavy falling objects and compression.

Because steel is dense, these boots are typically heavier than modern alternatives. They are often the standard choice for rigorous industries like construction where maximum impact resistance is required.

Alloy Toes (Lightweight Metals)

Alloy safety toes are typically manufactured from aluminum or titanium. These materials maintain the structural integrity and strength of steel but significantly reduce the weight of the toe cap.

Despite being lighter, they are still metallic. This means they share some conductive properties with steel but offer a less fatiguing experience for workers who walk significant distances.

Composite Toes (Non-Metallic Synthetics)

Composite toes are constructed from strong, non-metal materials. References indicate these commonly include carbon fiber, fiberglass, plastic, or Kevlar.

These toes are often thicker than metal caps to achieve the same safety rating, potentially creating a slightly bulkier silhouette. However, they provide unique benefits regarding weight and electrical resistance.

Understanding the Trade-offs

Weight vs. Fatigue

Steel is the heaviest option, which can lead to increased leg fatigue over long shifts. Alloy and composite toes are specifically designed to mitigate this, offering a lighter-weight alternative that maintains structural integrity.

Temperature Conductivity

Metal toes (steel and alloy) conduct temperature. In extreme cold, a steel toe can make your toes feel colder; in heat, it can warm up. Composite materials are poor conductors, making them the superior choice for working in extreme weather conditions.

Security and Magnetism

Steel and alloy toes will set off metal detectors. Composite boots are non-metallic, making them essential for workers in airports, nuclear plants, or high-security facilities who pass through checkpoints daily.

Making the Right Choice for Your Environment

To select the correct safety toe, you must look beyond the safety rating and consider your daily environment.

- If your primary focus is maximum durability and cost-effectiveness: Choose steel toes, as they offer the most robust protection against sharp or heavy objects in construction settings.

- If your primary focus is reducing fatigue while maintaining a slim profile: Choose alloy toes (aluminum or titanium), which offer the strength of metal at a much lower weight.

- If your primary focus is electrical safety or security checkpoints: Choose composite toes, as they are non-conductive, non-magnetic, and perform better in extreme temperatures.

The best safety boot is one that protects your feet from hazards without becoming a hindrance to your movement or comfort.

Summary Table:

| Material Type | Key Characteristics | Best For |

|---|---|---|

| Steel Toes | Maximum durability, heavy, cost-effective | Construction, heavy industry |

| Alloy Toes | Lightweight metal, strong, slim profile | Reducing fatigue, long shifts |

| Composite Toes | Non-metallic, non-conductive, lightweight | Electrical safety, security checkpoints, extreme temperatures |

Need the perfect safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety toe boots—whether you require the traditional strength of steel, the lightweight advantage of alloy, or the specialized safety of composite materials.

We can help you select or customize the ideal boot to protect your workers without hindering their comfort or productivity.

Contact our experts today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Are steel toe boots only for construction workers? Discover the Right Safety Footwear for Your Industry

- How often should steel toe boots be replaced? A Guide to Maximizing Safety & Value

- What safety standards do steel toe boots comply with? Understanding ASTM F2413 and OSHA 1910.136

- What is the primary benefit of wearing steel toe boots? Uncompromising Protection Against Crushing Injuries

- What are the key features of steel toe shoes? Maximum Impact Protection for Industrial Work

- What are the characteristics of steel toe safety boots? Maximum Protection, Key Trade-offs

- What are the benefits of wearing proper work socks with steel toe boots? Boost Comfort & Safety

- What are the differences between steel toe and composite toe work boots? Choose the Right Safety for Your Job