Prioritizing comfort in a safety-toe boot is not a luxury; it's a fundamental requirement for performance and long-term health. The most critical factors determining comfort are the precision of the fit, the weight and material of the boot, the quality of the insole and midsole system, and the breathability of the upper materials. A boot that fails in any of these areas can lead to fatigue, pain, and even injury.

True comfort in safety footwear is a system, not a single feature. It is the result of a precise fit working in concert with modern materials and supportive construction to reduce fatigue and prevent injury over thousands of steps on the job.

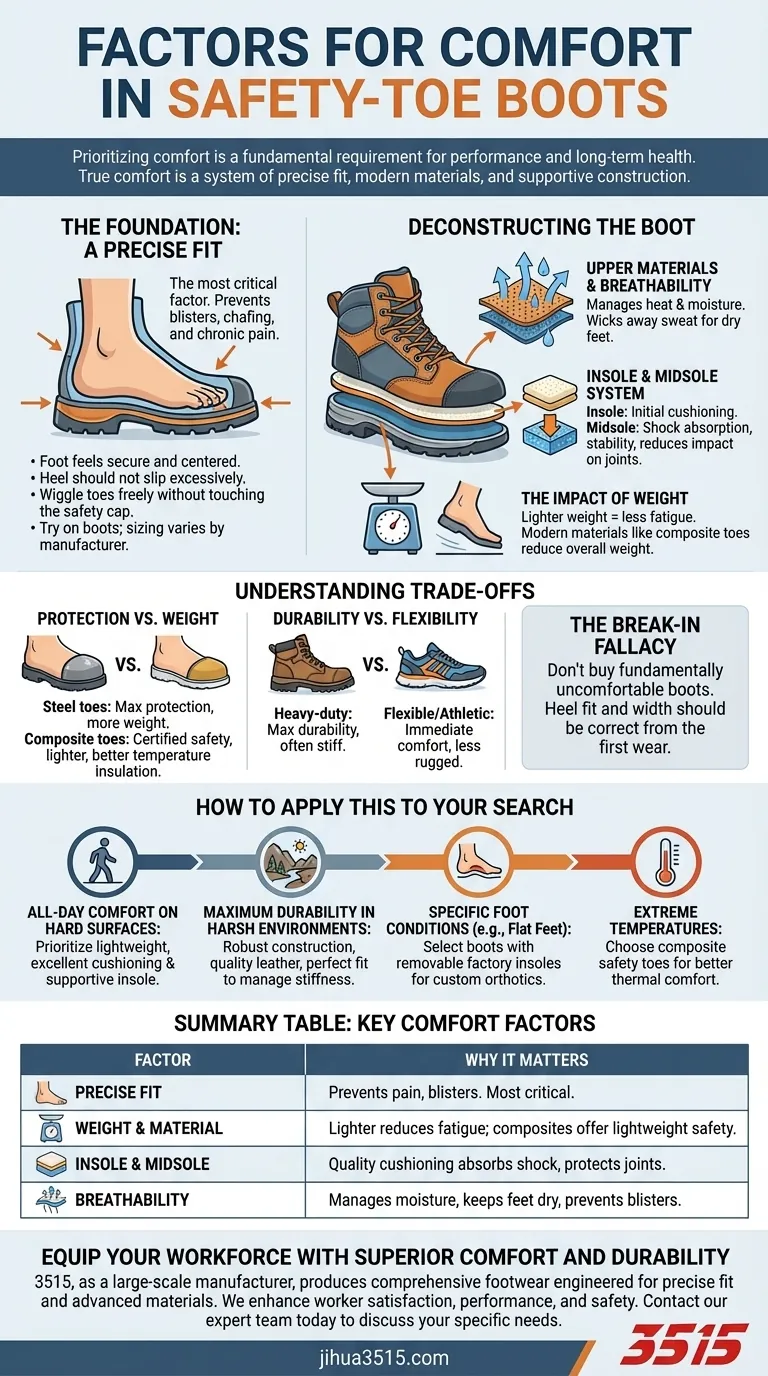

The Foundation of Comfort: Achieving a Precise Fit

An improper fit will undermine every other comfort feature a boot has. It is the single most important factor to get right, as it directly impacts both safety and daily endurance.

Why Fit Overrides All Else

A boot that is too tight or too loose can cause immediate problems like blisters and chafing. Over time, it can lead to more serious conditions like ingrown toenails, hammertoes, and chronic foot pain.

Key Indicators of a Proper Fit

When trying on boots, your foot should feel secure and centered. Your heel should not lift or slip excessively when you walk, and you must have enough room to wiggle your toes freely without them touching the rigid safety cap.

The Manufacturer Variable

Boot sizing is not standardized across manufacturers. A size 10 in one brand may fit completely differently from a size 10 in another, making it essential to try boots on before purchasing.

Deconstructing the Boot's Core Components

Beyond the initial fit, the materials and construction of the boot dictate how it will feel and perform throughout a long workday.

The Insole and Midsole System

The insole is the removable layer your foot rests on, providing initial cushioning. The midsole is the core support structure that absorbs shock and provides stability. A quality system reduces the impact on your feet, knees, and back.

Upper Materials and Breathability

The materials used for the main body of the boot—often leather or synthetic fabrics—determine its flexibility and ability to manage heat. A breathable lining is critical for wicking moisture away, keeping your feet dry and preventing blisters.

The Impact of Weight

Every ounce on your feet requires more energy to lift with each step. Modern boots often use lightweight composite safety toes and advanced sole materials to reduce overall weight, which directly translates to less fatigue at the end of the day.

Understanding the Trade-offs

Selecting the right safety boot always involves balancing competing priorities. Understanding these compromises is key to making an informed decision.

Protection vs. Weight

Traditional steel toes offer maximum protection but add significant weight. Newer composite toes provide certified safety with less weight and better insulation from temperature, but they can sometimes have a slightly bulkier profile.

Durability vs. Flexibility

Heavy-duty, rugged boots are built for maximum durability but are often stiff and require a "break-in" period. More flexible, athletic-style safety shoes offer immediate comfort but may not withstand the same level of abuse.

The "Break-In" Fallacy

While a quality leather boot will mold to your foot over time, you should not buy a boot that is fundamentally uncomfortable or ill-fitting. The fit around your heel and the width across your foot should feel correct from the very first wear.

How to Apply This to Your Search

Making the right choice depends on your specific needs, work environment, and foot type.

- If your primary focus is all-day comfort for walking on hard surfaces: Prioritize a lightweight boot with excellent midsole cushioning and a high-quality, supportive insole.

- If your primary focus is maximum durability in a harsh environment: Choose a boot with a robust construction and high-quality leather, ensuring the fit is perfect to manage the inherent stiffness.

- If you have specific foot conditions (like flat feet or plantar fasciitis): Select a boot with a removable factory insole so you can easily replace it with a custom or specialized orthotic for proper arch support.

- If you work in extreme temperatures: Look for a boot with a composite safety toe, which does not conduct heat or cold like steel, to improve thermal comfort.

Ultimately, the right safety boot is the one you forget you are wearing.

Summary Table:

| Key Comfort Factor | Why It Matters |

|---|---|

| Precise Fit | Prevents blisters, chafing, and long-term foot pain; the most critical factor. |

| Weight & Material | Lighter boots reduce fatigue; modern composites offer safety with less weight. |

| Insole & Midsole | Quality cushioning absorbs shock, protecting feet, knees, and back. |

| Breathability | Manages moisture to keep feet dry and comfortable, preventing blisters. |

Ready to equip your workforce with safety boots that deliver superior comfort and durability?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with a focus on the precise fit, advanced materials, and supportive construction detailed above. We help you enhance worker satisfaction, performance, and safety.

Contact our expert team today to discuss your specific needs and discover how we can be your trusted manufacturing partner.

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

People Also Ask

- Why are safety shoes important in the construction sector? Essential Protection for Your Workforce

- How does the simulation of Agricultural ATV dynamics impact Agricultural Safety Shoes? Design for Complex Terrain

- Why is explicit dynamic FEA software necessary for safety shoe toe cap performance? Precision Engineering for Safety

- What tips help in selecting appropriate safety footwear? A Guide to Matching Hazards & Fit

- How is abrasion resistance achieved in safety footwear? Choose Durable Materials for Long-Lasting Protection

- How do safety shoes prevent Podoconiosis? Essential Barrier Protection for Volcanic Soil Regions

- Why is it mandatory for personnel to wear anti-slip industrial safety shoes during salt loading? Prevent Slip Hazards

- What features should be considered when selecting oil resistant safety boots? Ensure Maximum Protection & Comfort