In safety footwear, abrasion resistance is primarily achieved by using modern materials like synthetic leather or by applying specialized protective coatings to conventional leather. These methods are engineered to create a durable outer surface that withstands the constant friction, scuffs, and scrapes common in demanding work environments, thereby preventing premature wear and tear.

The core principle of abrasion resistance is not just about using "tough" materials, but about a deliberate engineering choice. Footwear either relies on the inherent durability of its core material or uses a sacrificial surface coating to protect a less-resistant base.

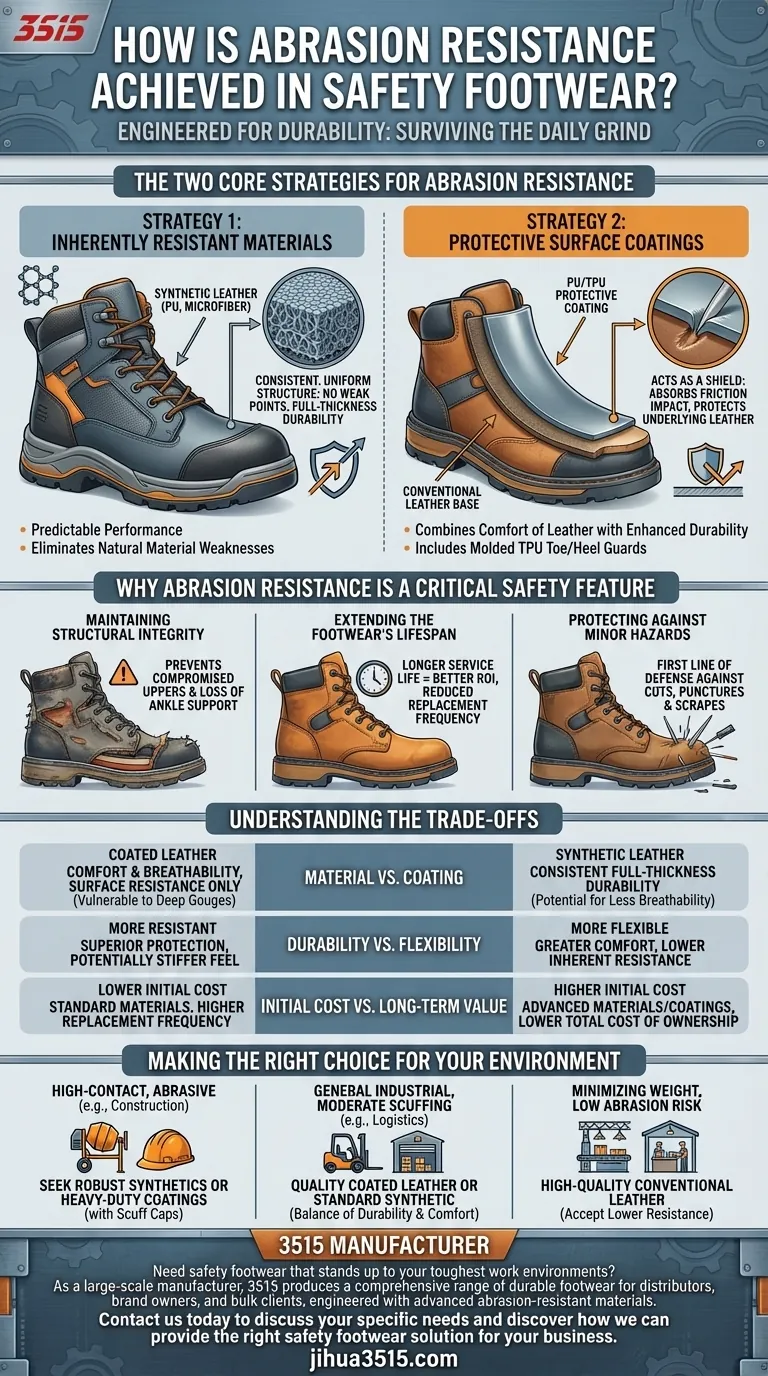

The Two Core Strategies for Abrasion Resistance

To understand how a work boot holds up to daily abuse, we must look at the two fundamental approaches manufacturers take to engineer its upper material. Each has distinct properties and applications.

Strategy 1: Inherently Resistant Materials

The most direct approach is to construct the footwear from a material that is intrinsically durable and resistant to friction.

Synthetic leathers, such as those made from polyurethane (PU) or microfiber, are prime examples. Their polymer-based structure is uniform and consistent, meaning their resistance to wear is not just skin-deep but extends through the entire thickness of the material.

This uniformity eliminates the weak points that can exist in natural materials, providing predictable and reliable performance against constant scraping and contact.

Strategy 2: Protective Surface Coatings

The second strategy involves taking a base material, often high-quality conventional leather, and enhancing it with a protective layer.

These added coatings, typically made of polyurethane (PU) or thermoplastic polyurethane (TPU), act as a shield. They form a resilient barrier on the surface that absorbs the impact of friction and prevents scuffs from damaging the underlying leather.

This method allows manufacturers to combine the desirable properties of natural leather, like breathability and comfort, with the enhanced durability required for a safety-grade product. Specialized reinforcements, like molded TPU toe or heel guards, are an extreme form of this principle.

Why Abrasion Resistance is a Critical Safety Feature

While features like steel toes and slip-resistant soles get more attention, the abrasion resistance of the upper is fundamental to the footwear's long-term safety and performance.

Maintaining Structural Integrity

Constant abrasion wears down the footwear's upper, which is the primary structure holding everything together. A compromised upper can reduce ankle support and may eventually expose internal safety components, rendering them ineffective.

Extending the Footwear's Lifespan

Abrasion is the most common reason safety footwear is retired from service. A boot with high abrasion resistance will last significantly longer, ensuring a better return on investment and reducing the frequency of replacement.

Protecting Against Minor Hazards

A robust, abrasion-resistant upper serves as the first line of defense. It prevents minor cuts, punctures, and scrapes from sharp objects or rough surfaces from ever reaching the foot.

Understanding the Trade-offs

Selecting the right material is a balance of competing factors. No single solution is perfect for every application, and understanding the trade-offs is key to making an informed decision.

Material vs. Coating

Coated leather can offer the comfort and breathability of a natural material, but its abrasion resistance is only on the surface. A deep gouge that penetrates the coating will expose the less-durable leather underneath.

Synthetic leather, conversely, offers consistent durability throughout. However, some lower-quality synthetics may offer less breathability compared to high-grade natural leather.

Durability vs. Flexibility

There is often a direct trade-off between a material's resistance and its flexibility. Thicker coatings and more rigid synthetic materials provide superior protection against abrasion but can make the footwear feel stiff, potentially impacting comfort during long periods of wear.

Initial Cost vs. Long-Term Value

Footwear engineered with advanced, highly abrasion-resistant materials or coatings typically has a higher initial purchase price. However, this upfront cost is frequently offset by a significantly longer service life, leading to a lower total cost of ownership over time.

Making the Right Choice for Your Environment

The ideal level of abrasion resistance depends entirely on the specific hazards of your work environment.

- If your primary focus is high-contact, abrasive environments (e.g., construction, masonry, mechanics): Seek footwear with robust synthetic uppers or heavy-duty coatings, often supplemented with external scuff caps on the toe.

- If your primary focus is general industrial use with moderate scuffing (e.g., logistics, factory floors): A quality coated leather or a standard synthetic material provides an excellent balance of durability, comfort, and value.

- If your primary focus is minimizing weight and maximizing flexibility with low abrasion risk: A high-quality conventional leather may be sufficient, but you must accept its lower inherent resistance to wear.

Ultimately, understanding how abrasion resistance is engineered allows you to make an informed choice that directly aligns with the safety demands and longevity required by your work.

Summary Table:

| Strategy | Key Material/Coating | Primary Benefit |

|---|---|---|

| Inherently Resistant Materials | Synthetic Leather (PU, Microfiber) | Consistent, full-thickness durability |

| Protective Surface Coatings | PU or TPU Coatings on Leather | Combines leather comfort with a durable shield |

Need safety footwear that stands up to your toughest work environments?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots engineered with advanced abrasion-resistant materials and coatings to ensure long-term protection and value.

Contact us today to discuss your specific needs and discover how we can provide the right safety footwear solution for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.