Beyond just oil resistance, selecting the right safety boot is about choosing a complete system of protection tailored to your specific work environment. The key is to look at how the outsole material, the protective toe cap, the electrical hazard rating, and the overall construction work together to mitigate the risks you face daily.

The most effective oil-resistant safety boots combine a specialized outsole compound for grip with a certified safety toe and the correct electrical hazard rating for your job site. Simply being "oil-resistant" is not enough; true safety lies in matching the boot's specific, rated features to your known workplace hazards.

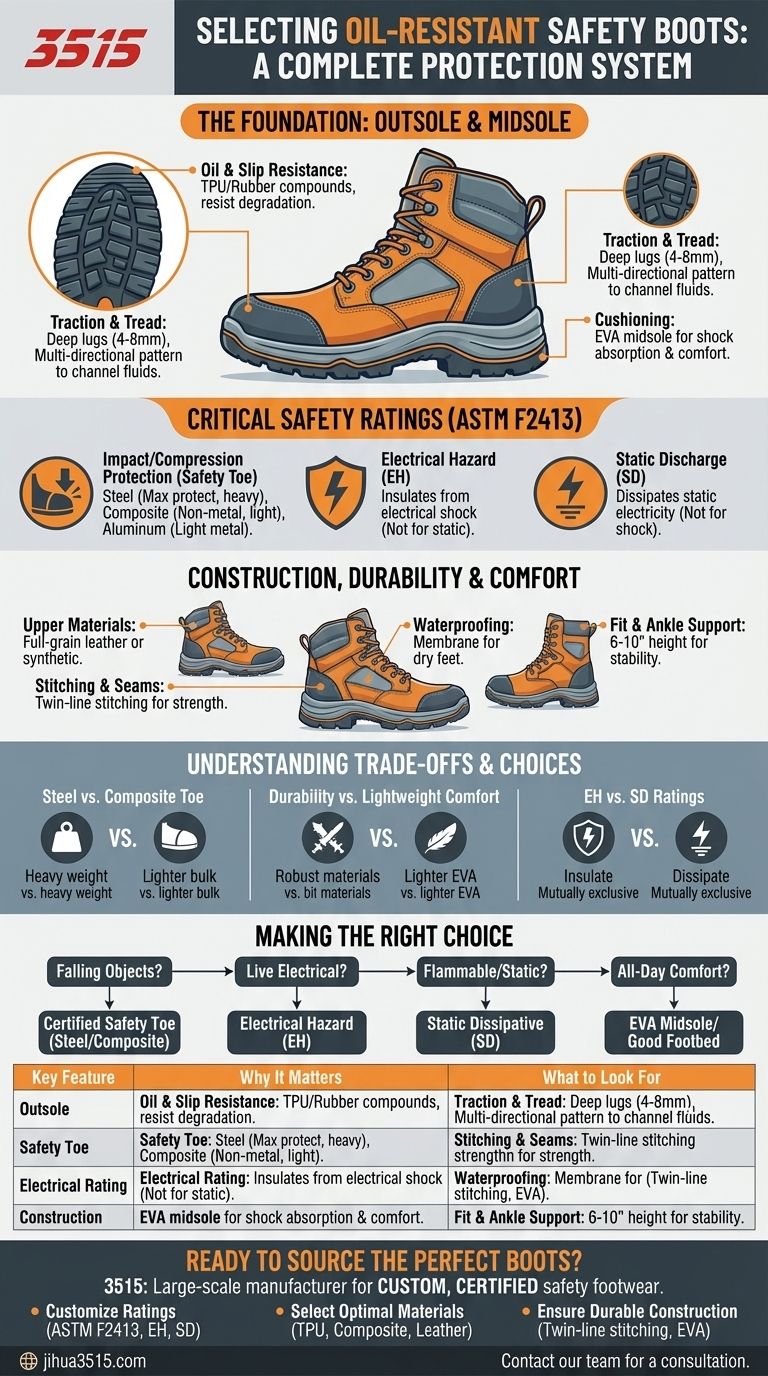

The Foundation: The Outsole and Midsole

The part of the boot that meets the ground is your first line of defense. Its design and material composition are critical for preventing slips and ensuring long-term comfort.

Oil and Slip Resistance

The term "oil resistant" refers specifically to the outsole's material compound, which is designed not to degrade or swell when exposed to petrochemicals. This preserves the integrity and grip of the sole over time.

Common high-performance outsole materials include Thermo-Polyurethane (TPU), known for its excellent resistance to chemicals and abrasion, and Rubber, which offers superior durability and traction.

Traction and Tread Design

Resistance to oil is useless without physical grip. Look for boots with deep lugs (4mm to 8mm) and a multi-directional tread pattern. This design actively channels oil and water away from the sole's surface, ensuring maximum contact with the ground to prevent slips.

Cushioning and Support

The midsole is the primary layer for shock absorption and comfort. Materials like Ethylene-Vinyl Acetate (EVA) provide a lightweight, cushioning layer that significantly reduces fatigue for workers who are on their feet all day. A supportive midsole is crucial for preventing strain on your feet, knees, and back.

Critical Safety Ratings and Protection

Safety boots are rated according to standardized tests that certify their protective capabilities. Understanding these ratings is non-negotiable for making a safe choice.

Impact and Compression Protection (The Safety Toe)

This is the most fundamental safety feature, protecting your toes from falling objects and crushing forces. The choice of material affects weight, comfort, and application.

- Steel Toe: The traditional standard, offering maximum protection. It is also the heaviest option and conducts heat and cold.

- Composite Toe: Made from non-metal materials like Kevlar, carbon fiber, or plastic. It is lighter than steel, does not conduct temperature, and is ideal for metal-free work environments.

- Aluminum Toe: A lightweight metal option that offers similar protection to steel but in a less bulky profile.

Electrical Hazard (EH) Protection

An EH rating signifies that the footwear is constructed with non-conductive, electrical shock-resistant soles and heels. These boots are designed to protect you from accidental contact with live electrical circuits, a critical feature for electricians and maintenance workers.

Static Discharge (SD) Protection

Do not confuse this with EH protection. Static Dissipative (SD) boots are designed to reduce the buildup of static electricity by conducting it from your body to the ground. This is essential in environments where a static spark could ignite flammable materials, such as in oil and gas operations or around sensitive electronics.

Understanding Safety Standards (ASTM F2413)

In the United States, look for boots that meet ASTM F2413 standards. This label confirms the boot has been independently tested and certified for its stated protections, such as impact resistance (I/75), compression resistance (C/75), and electrical hazard (EH) ratings.

Construction, Durability, and Comfort

A boot's overall build quality determines its lifespan and how comfortable it will be during long shifts.

Upper Materials

Full-grain leather is a premium material known for its exceptional durability, breathability, and water resistance. Synthetic fabrics can offer a lighter-weight alternative and are often used in combination with waterproof membranes.

Stitching and Seams

Look for strong construction methods like twin-line stitching. Reinforced seams add significant strength and prevent the boot from coming apart under high stress, extending its service life.

Waterproofing

In many industrial settings, you will encounter water, mud, or other liquids. A waterproof membrane or properly treated leather is crucial for keeping your feet dry, preventing discomfort, and maintaining foot health.

Fit and Ankle Support

A proper fit is essential for both safety and comfort. For added stability on uneven surfaces, consider a boot height of 6 to 10 inches, which provides crucial ankle support and helps prevent sprains and twists.

Understanding the Trade-offs

Choosing the perfect boot always involves balancing competing priorities. Being aware of these trade-offs will help you make a more informed decision.

Steel Toe vs. Composite Toe

Steel offers maximum protection and is often more affordable, but it is heavy and can become uncomfortable in extreme temperatures. Composite toes are lighter and non-conductive but can make the toe box of the boot feel bulkier to achieve the same safety rating.

Durability vs. Lightweight Comfort

The most durable boots often use robust materials like thick leather and solid rubber outsoles, which can be heavy and require a break-in period. Lighter boots with synthetic uppers and EVA midsoles offer immediate comfort but may not withstand the same level of abuse.

EH vs. SD Ratings

These two protections are designed for opposite purposes and are mutually exclusive. EH boots insulate you from electricity, while SD boots dissipate static charge to the ground. You must choose the specific rating required for your job; one cannot do the work of the other.

Making the Right Choice for Your Environment

Your final decision should be guided by a clear risk assessment of your workplace.

- If your primary focus is protection from falling objects and machinery: Prioritize a boot with a certified safety toe (steel or composite) and durable full-grain leather construction.

- If your primary focus is working around live electrical circuits: You must select a boot that is explicitly marked with an Electrical Hazard (EH) rating.

- If your primary focus is preventing sparks in a flammable environment: Your only safe choice is a boot with a Static Dissipative (SD) rating.

- If your primary focus is all-day comfort on hard surfaces: Look for a boot with a significant EVA midsole for cushioning and a well-designed, supportive footbed.

Ultimately, the right safety boot is a critical piece of personal protective equipment that empowers you to perform your job safely and effectively.

Summary Table:

| Key Feature | Why It Matters | What to Look For |

|---|---|---|

| Outsole Material | Prevents slips and degradation from oil exposure. | TPU or rubber compounds with deep, multi-directional treads. |

| Safety Toe Cap | Protects toes from impact and compression. | Steel, composite, or aluminum toe certified to ASTM F2413. |

| Electrical Rating | Guards against electrical hazards or static discharge. | EH (Electrical Hazard) or SD (Static Dissipative) rating. |

| Construction & Comfort | Ensures durability and all-day wearability. | Full-grain leather, EVA midsole, waterproofing, and proper fit. |

Ready to Source the Perfect Oil-Resistant Safety Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes, tailored to meet specific workplace hazards and comfort requirements.

We can help you:

- Customize boots with the exact safety ratings (ASTM F2413, EH, SD) your market demands.

- Select optimal materials like oil-resistant TPU outsoles, composite toes, and breathable leather uppers.

- Ensure durable construction with features like twin-line stitching and cushioned EVA midsoles for long-lasting comfort.

Let’s discuss your specific needs and volume requirements.

Contact our expert team today for a consultation and to request a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What key features enhance the functionality of firefighter boots? Built for Extreme Safety & Performance

- How does defining specific friction interface models in FEA assist in predicting safety shoe toe cap failure modes?

- What specific protective features do professional safety shoes provide for stroke survivors? Enhance Workplace Safety

- What is a recommended tip for putting on safety shoes? Protect Your Investment with One Simple Tool

- What specific mechanical protections do industrial safety shoes provide in cable factories? Expert Guide for Max Safety

- How do safety shoes protect against impacts and vibrations? Maximize Safety and Agility in Rock Breaking & Drilling

- What is the purpose of the midsection with insert for ladder support in safety footwear? Enhance Stability & Safety

- Why is it mandatory for personnel to wear anti-slip industrial safety shoes during salt loading? Prevent Slip Hazards