Selecting the right safety footwear is a critical decision based on a systematic process, not just a simple purchase. The most effective approach involves first assessing your specific workplace hazards, then matching those risks to certified protective features, and finally ensuring a proper, comfortable fit to guarantee the footwear is worn consistently and correctly.

The core principle of selecting safety footwear is not to find a boot with the most features, but to conduct a specific risk assessment of your environment first. The right choice directly matches the identified hazards—such as impact, puncture, or electrical risks—to the corresponding certified protections, making proper fit the final, non-negotiable step for compliance and safety.

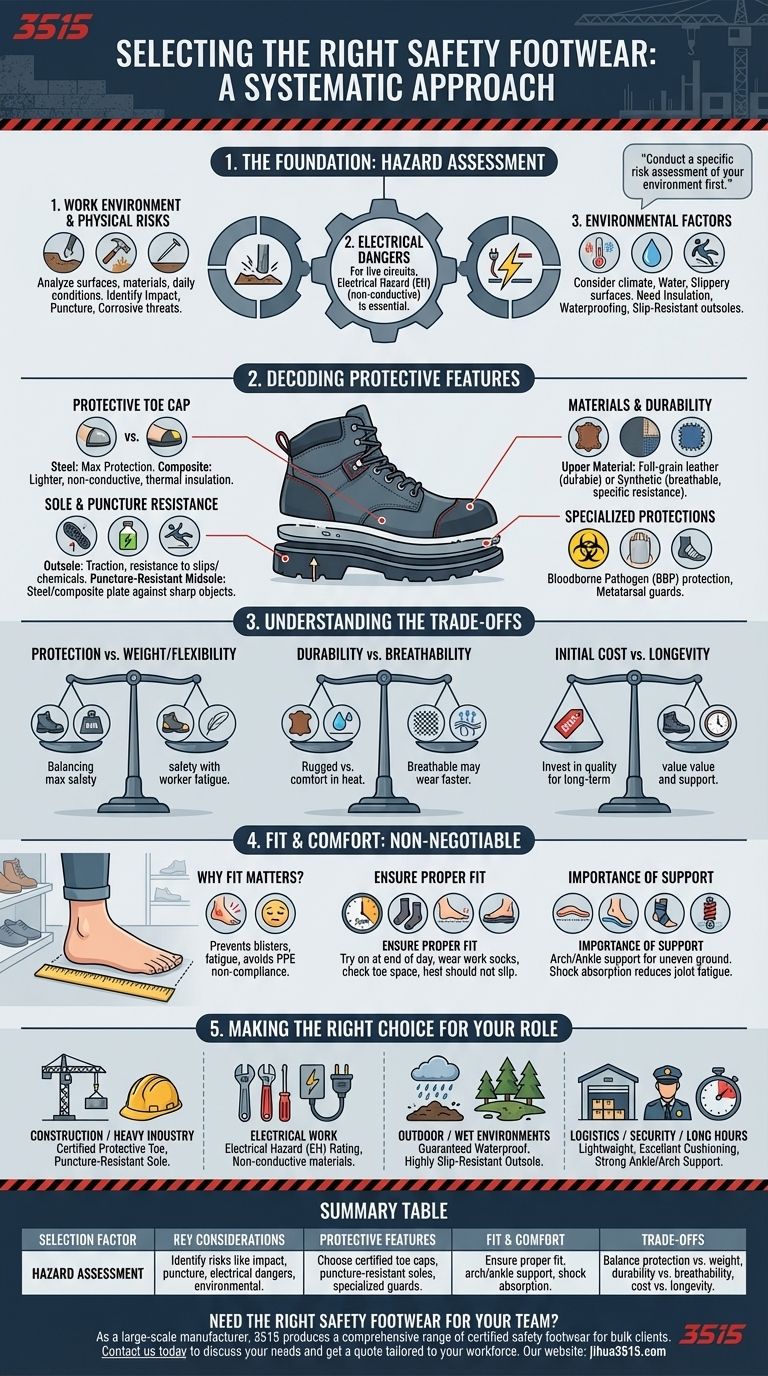

The Foundation: A Thorough Hazard Assessment

Before looking at a single boot, you must analyze the environment where it will be used. This foundational step dictates every subsequent decision.

Start with Your Work Environment

The context of your work is the most important factor. Ask what surfaces you walk on, what materials you handle, and what conditions you are exposed to daily.

Identify Specific Physical Risks

Determine the primary threats. This could include the risk of heavy objects falling (impact), sharp objects on the ground (puncture), or exposure to corrosive chemicals.

Evaluate Electrical Dangers

If you work near live circuits, electrical hazard (EH) protection is essential. This requires footwear built with non-conductive materials designed to insulate you from the ground.

Consider Environmental Factors

Your daily climate and conditions play a huge role. This includes exposure to extreme heat or cold, water, and slippery surfaces, which demand features like insulation, waterproofing, and high-traction, slip-resistant outsoles.

Decoding Key Protective Features

Once you understand the risks, you can evaluate footwear based on its specific protective components. Each part of the shoe is engineered to counter a particular hazard.

The Protective Toe Cap

This is the most well-known safety feature. Steel toes offer maximum protection against impact and compression, while composite (non-metallic) toes are lighter, don't conduct electricity, and are better for high-security or extreme temperature environments.

Sole Construction and Puncture Resistance

The outsole provides traction and resistance to slips, chemicals, and abrasion. A puncture-resistant midsole plate, often made of steel or flexible composites, protects the bottom of your foot from nails and other sharp objects.

Materials and Durability

The upper material dictates the footwear's durability, breathability, and resistance to environmental factors. Full-grain leather is extremely durable, while synthetic materials can offer better breathability or specific chemical resistance.

Specialized Protections

For unique roles, look for specialized features. This can include bloodborne pathogen (BBP) protection for public safety professionals or metatarsal guards for workers at risk of impacts to the top of the foot.

Understanding the Trade-offs

No single safety boot is perfect for every situation. Choosing the right one involves balancing competing priorities.

Protection vs. Weight and Flexibility

Maximum protection often means more weight. A heavy-duty steel toe boot is ideal for a construction site but can cause fatigue for a worker who walks several miles a day. Lighter composite materials offer a trade-off between comfort and ultimate impact resistance.

Durability vs. Breathability

Rugged, waterproof materials like treated leather are highly durable but can be less breathable, leading to discomfort in hot conditions. More breathable synthetic uppers may offer more comfort but wear out faster.

Initial Cost vs. Longevity

The cheapest option is rarely the most cost-effective. A well-constructed boot made from durable materials will last longer and provide better long-term support. Remember to factor in the cost of replacing insoles every few months to maintain comfort and support.

Fit and Comfort: The Non-Negotiable Elements

The most technologically advanced safety boot is useless if it's too uncomfortable to wear. Proper fit is a safety feature in itself.

Why Fit Is a Safety Requirement

An ill-fitting boot can cause blisters, fatigue, and long-term foot problems. More importantly, it creates a distraction and can lead to a worker modifying or avoiding their personal protective equipment, completely negating its value.

How to Ensure a Proper Fit

Always try on footwear at the end of the day when your feet are slightly swollen. Wear the same type of socks you use for work and ensure there is a small amount of space for your toes to move. Your heel should not slip excessively when you walk.

The Importance of Support

Look for adequate arch support and ankle support, especially if you work on uneven surfaces or stand for long periods. Good shock absorption in the heel and footbed reduces fatigue and protects your joints.

Making the Right Choice for Your Role

With a clear understanding of the principles, you can select the right footwear by aligning features with your primary job function.

- If your primary focus is construction or heavy industry: Prioritize a certified protective toe (steel or composite) and a puncture-resistant sole.

- If your primary focus is electrical work: Ensure the footwear has a clear Electrical Hazard (EH) rating and is built from non-conductive materials.

- If your primary focus is outdoor or wet environments: Select footwear with guaranteed waterproof construction and a highly slip-resistant outsole.

- If your primary focus is logistics, security, or long hours on your feet: Emphasize lightweight construction, excellent cushioning, and strong ankle and arch support to minimize fatigue.

Ultimately, investing in the correct safety footwear is a direct investment in your own health and ability to perform your job safely.

Summary Table:

| Selection Factor | Key Considerations |

|---|---|

| Hazard Assessment | Identify risks like impact, puncture, electrical dangers, and environmental conditions. |

| Protective Features | Choose certified toe caps (steel/composite), puncture-resistant soles, and specialized guards. |

| Fit & Comfort | Ensure proper fit, arch/ankle support, and shock absorption for all-day wearability. |

| Trade-offs | Balance protection vs. weight, durability vs. breathability, and initial cost vs. longevity. |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet specific hazard requirements while ensuring superior comfort and durability.

Contact us today to discuss your needs and get a quote tailored to your workforce.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What are the key advantages of composite-toe boots? Lighter, Safer, and More Comfortable

- What is the significance of using industrial Safety Shoes in starch factories? Enhance Grip in Wet Processing Areas

- What is the specialized application value of professional protective footwear in high-risk infection control? Guide 2024

- What are the benefits of using waterproof safety shoes during mining road maintenance and dust suppression activities?

- What are the standard European classifications for safety footwear? A Guide to EN ISO 20345

- What is the primary purpose of safety shoes? Your Ultimate Guide to Workplace Foot Protection

- What is the physiological importance of high-density shock-absorbing midsoles? Protect Workers' Cardiovascular Health

- What is the function of pressure insoles in safety shoes? High-Precision Gait Analysis and Load Assessment