Safety shoes in the construction sector are the primary defense against severe physical trauma and environmental hazards. They serve as essential Personal Protective Equipment (PPE) to prevent injuries from falling heavy objects, punctures from sharp debris like nails, and slips on unstable or slick surfaces.

Safety footwear goes beyond mere compliance; it provides critical stability and a specific layer of armor against crushing, piercing, and chemical risks. For construction environments, this typically necessitates footwear meeting S3 or S5 safety standards.

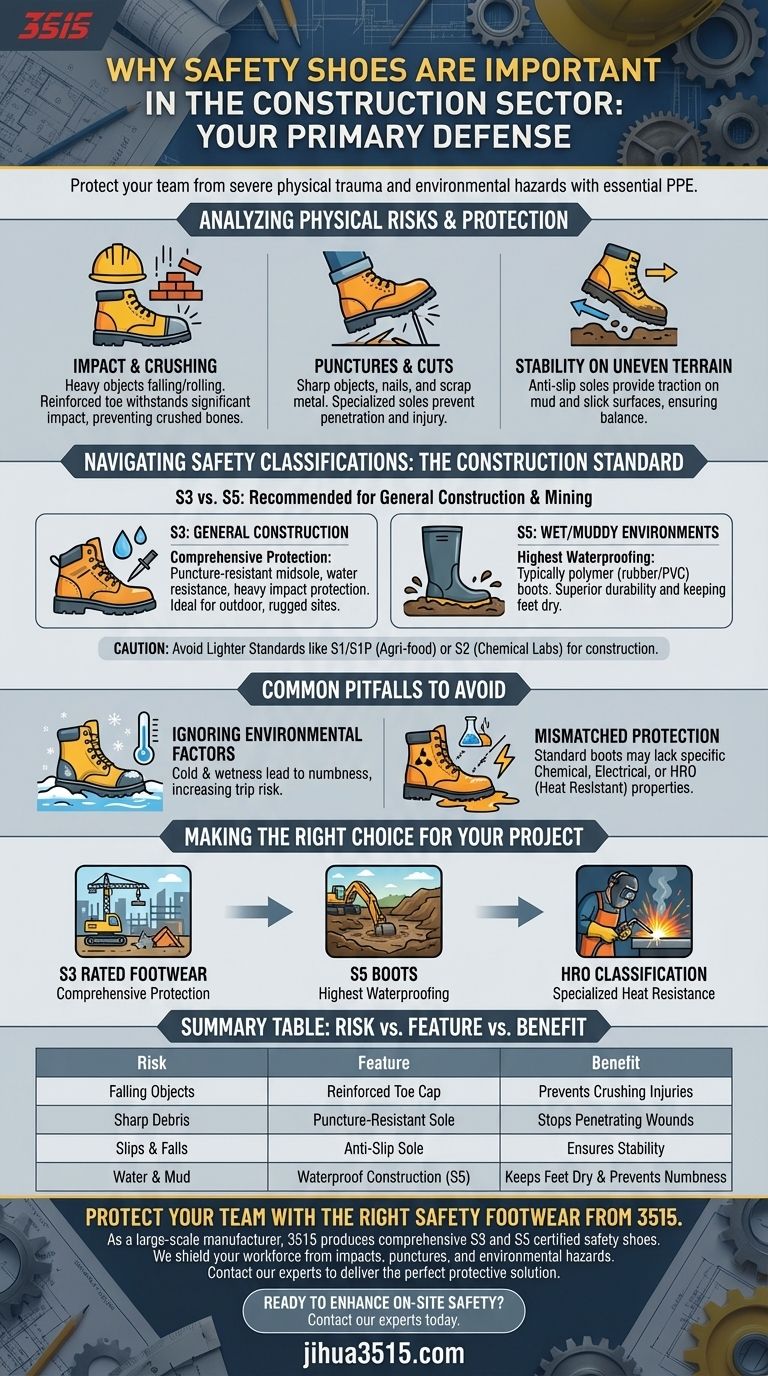

Analyzing the Physical Risks

Construction sites present a unique combination of kinetic and environmental dangers that ordinary footwear cannot mitigate.

Protection Against Impact and Crushing

The most immediate risk on a site involves heavy objects falling or rolling onto the feet. Safety shoes reinforce the toe area to withstand significant impact, preventing crushed bones and long-term disability.

Defense Against Punctures and Cuts

Construction floors are often littered with sharp piercing edges, scrap metal, and nails. Specialized soles act as a barrier to stop these sharp objects from penetrating the shoe and injuring the foot.

Stability on Uneven Terrain

Slips and falls are a leading cause of workplace accidents. Safety shoes are engineered with anti-slip soles to provide traction on uneven, muddy, or slick surfaces, ensuring the worker maintains balance during heavy lifting.

Navigating Safety Classifications

Not all safety shoes offer the same level of protection. Understanding the specific classification codes is vital for matching the gear to the environment.

The Construction Standard: S3 and S5

For general construction and mining sites, S3 or S5 classifications are the recommended standard. These ratings ensure the footwear includes water resistance and a puncture-resistant midsole, which are non-negotiable requirements for outdoor, rugged sites.

Specialized Industry Standards

It is crucial not to confuse construction requirements with lighter industry standards. For example, S1 or S1P shoes are suitable for the agri-food industry, and S1 or S2 generally suffice for chemical labs. However, these lower classifications often lack the heavy-duty water and puncture resistance required for active construction zones.

Common Pitfalls to Avoid

Selecting the wrong footwear can create a false sense of security while leaving workers vulnerable.

Ignoring Environmental Factors

Focusing solely on impact resistance while ignoring elements like cold weather or water can lead to different injuries. Shoes must keep feet warm and dry to prevent numbness, which indirectly increases the risk of tripping or losing balance.

Mismatched Chemical and Electrical Protection

Standard construction boots may not protect against specific hazards like heavy chemical spills or high-voltage risks. If your site involves welding or volatile chemicals, standard S3 boots may need additional Hro (heat resistant) classifications or specific chemical resistance properties.

Making the Right Choice for Your Project

To ensure safety and compliance, you must map the footwear classification to the specific daily tasks of your workforce.

- If your primary focus is general construction: Opt for S3 rated footwear, which provides comprehensive protection against punctures, water penetration, and heavy impacts.

- If your primary focus is wet or muddy environments: Select S5 boots, as these are typically polymer (rubber/PVC) boots that offer the highest level of waterproofing and durability.

- If your primary focus is specialized high-heat work: Look for footwear with an Hro classification, often necessary for tasks like welding where contact heat is a risk.

Equipping your team with the correct classification of safety footwear is the foundational step in mitigating life-altering accidents on site.

Summary Table:

| Risk | Safety Shoe Feature | Benefit |

|---|---|---|

| Falling Objects | Reinforced Toe Cap | Prevents Crushing Injuries |

| Sharp Debris | Puncture-Resistant Sole | Stops Penetrating Wounds |

| Slips & Falls | Anti-Slip Sole | Ensures Stability on Uneven Terrain |

| Water & Mud | Waterproof Construction (S5) | Keeps Feet Dry and Prevents Numbness |

Protect your team with the right safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of S3 and S5 certified safety shoes and boots designed for the demanding conditions of the construction sector. We provide durable, compliant footwear for distributors, brand owners, and bulk clients, ensuring your workforce is shielded from impact, punctures, and environmental hazards.

Ready to enhance on-site safety and compliance? Contact our experts today to discuss your project's specific needs and discover how our production capabilities can deliver the perfect protective solution for your team.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Which organizations create and enforce safety footwear regulations? Understand ASTM and OSHA Roles

- What role do integrated pressure-sensing insoles play in safety shoes for assessing lower back disease risk?

- What factors should be considered for comfort in safety-toe boots? Ensure All-Day Comfort and Performance

- What are the advantages of using triangular prism meshes and second-order tetrahedral elements in safety shoe modeling?

- Why is comfort important in safety toe boots? Boost Worker Safety and Productivity

- What materials are used in alloy toe shoes? A Guide to Lightweight Safety Footwear

- What manufacturing processes are essential for Safety Shoes? Ensure Durability with Advanced Production Standards

- What materials are used for the upper part of safety footwear? Choose the Right Protection for Your Job