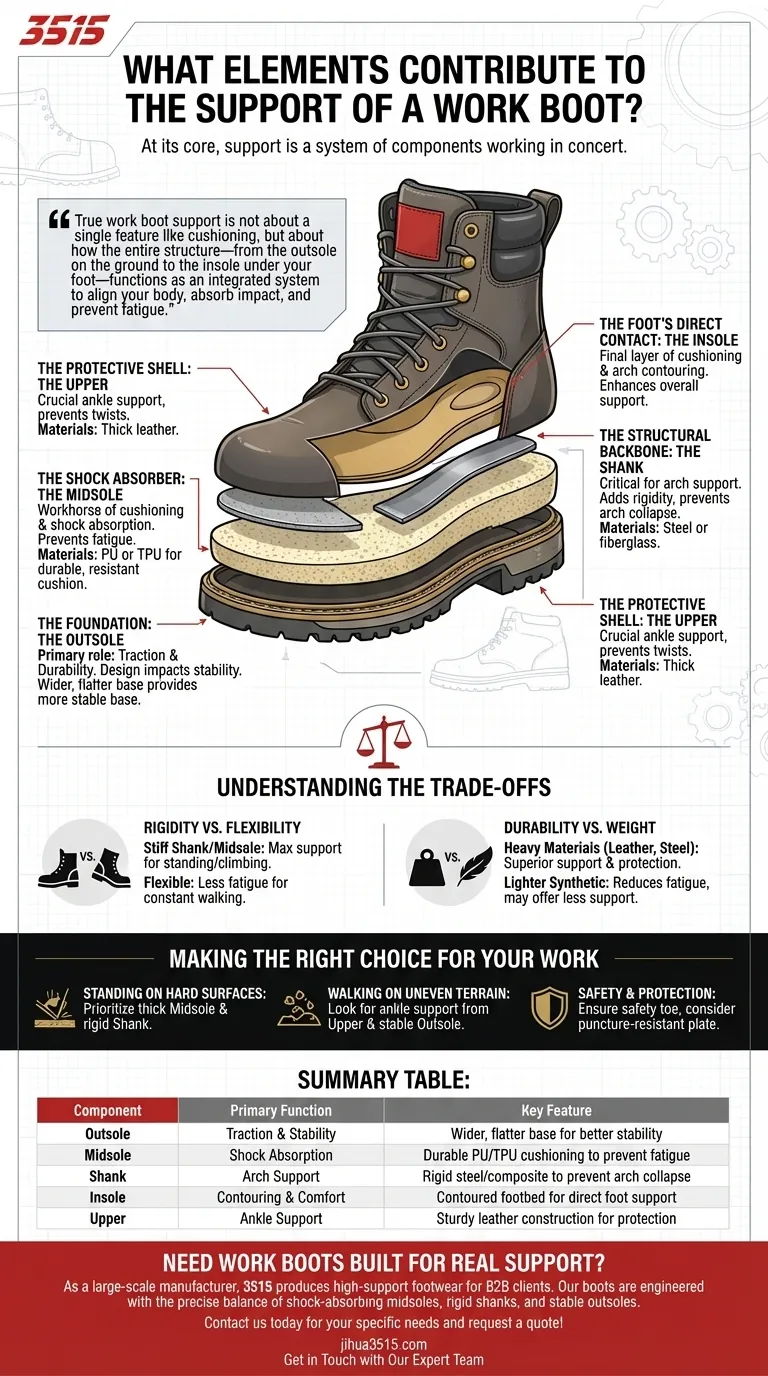

At its core, the support of a work boot is a result of a system of components working in concert. The primary elements contributing to this are the insole, the midsole, the internal shank, and the outsole, each playing a distinct role in creating a stable and protective foundation for your foot.

True work boot support is not about a single feature like cushioning, but about how the entire structure—from the outsole on the ground to the insole under your foot—functions as an integrated system to align your body, absorb impact, and prevent fatigue.

The Anatomy of a Supportive Work Boot

To understand support, you must look at the boot as a multi-layered structure. Each layer has a specific job, and their synergy determines the boot's performance.

The Foundation: The Outsole

The outsole is the bottom layer that makes direct contact with the ground. While its primary role is traction and durability, its design directly impacts stability, which is the first step in support.

A wider, flatter outsole provides a more stable base, especially on hard, even surfaces like concrete.

The Shock Absorber: The Midsole

Located between the outsole and your foot, the midsole is the workhorse of cushioning and shock absorption. It is critical for preventing the fatigue that comes from standing or walking on hard surfaces all day.

Materials like polyurethane (PU) or thermoplastic polyurethane (TPU) provide a durable, supportive cushion that resists compression over time.

The Structural Backbone: The Shank

The shank is arguably the most critical component for true arch support. It is a rigid piece of material, often steel or a composite like fiberglass, embedded between the midsole and insole.

Its purpose is to add rigidity to the arch area of the boot, preventing it from flexing or collapsing under your body weight. This is what provides lasting support and reduces strain on your arches, knees, and back.

The Foot's Direct Contact: The Insole

The insole, or footbed, is the removable layer your foot rests on directly. It provides the final layer of cushioning and arch contouring.

While factory insoles offer basic comfort, a high-quality insole can be tailored to your specific arch type, significantly enhancing the boot's overall support.

The Protective Shell: The Upper

The upper is the part of the boot that covers your foot. While not typically considered a primary support element, a well-constructed upper made from materials like thick leather provides crucial ankle support.

This helps prevent twists and sprains, particularly when working on uneven or unstable terrain.

Understanding the Trade-offs

Choosing the right boot requires balancing competing factors. What makes a boot exceptional in one scenario can be a drawback in another.

Rigidity vs. Flexibility

A boot with a very stiff shank and midsole provides maximum support for standing in place or climbing ladders. However, that same rigidity can feel clunky and fatiguing if your job requires constant walking and kneeling.

Durability vs. Weight

Heavier materials like thick leather and steel components (shanks, safety toes) offer superior support and protection. The trade-off is increased weight, which can contribute to leg fatigue over a long shift.

Lighter synthetic materials may reduce fatigue but often offer less structural support and durability in demanding environments.

Making the Right Choice for Your Work

The best boot is the one designed for your specific tasks and physical needs. Use these guidelines to prioritize features.

- If your primary focus is standing on hard surfaces: Prioritize a thick, high-quality midsole for shock absorption and a rigid shank to prevent your arches from collapsing.

- If your primary focus is walking on uneven terrain: Look for excellent ankle support from a sturdy upper and a stable outsole design to prevent slips and rolls.

- If your primary focus is safety and protection: Ensure the boot has the required safety toe (steel or composite) and consider features like a puncture-resistant plate, which adds to the boot's rigidity.

Ultimately, investing in a properly constructed and well-fitting work boot is a direct investment in your daily comfort, safety, and long-term health.

Summary Table:

| Component | Primary Function | Key Feature |

|---|---|---|

| Outsole | Traction & Stability | Wider, flatter base for better stability |

| Midsole | Shock Absorption | Durable PU/TPU cushioning to prevent fatigue |

| Shank | Arch Support | Rigid steel/composite to prevent arch collapse |

| Insole | Contouring & Comfort | Contoured footbed for direct foot support |

| Upper | Ankle Support | Sturdy leather construction for protection |

Need Work Boots Built for Real Support?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-support footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes, engineered with the precise balance of shock-absorbing midsoles, rigid shanks, and stable outsoles detailed in this article.

We help you provide footwear that protects your workforce's health and enhances productivity.

Contact us today to discuss your specific needs and request a quote!

Get in Touch with Our Expert Team

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the pros of Cement Construction? Discover Lightweight, Flexible Footwear

- Why is slip resistance a critical feature for safety boots? Prevent Secondary Accidents in Aluminum Processing Centers

- What are some key differences between traditional and modern engineer boots? Choose the Right Style for Your Needs

- What type of safety shoe is recommended for workers exposed to heavy machinery? Steel Toe Boots for Ultimate Protection

- How do wildland firefighting boots differ from other firefighting boots? Key Design & Safety Differences

- What should you consider when choosing composite toe work boots? A Guide to Safety, Comfort & Durability

- Why is comfort important in work boots for women? Boost Productivity & Safety

- What should you look for in the construction quality of work boots? Ensure Durability, Safety & Repairability