Cement construction is prized for three primary benefits: it creates footwear that is exceptionally lightweight, highly flexible, and comfortable right out of the box with minimal to no break-in period. This modern construction method involves bonding the shoe's upper directly to its outsole using a strong adhesive, which eliminates the need for bulky and rigid layers of stitching.

Cement construction prioritizes immediate comfort, flexibility, and a lower cost by sacrificing the long-term durability and repairability of traditionally stitched footwear. Understanding this core trade-off is the key to choosing the right shoe for your specific needs.

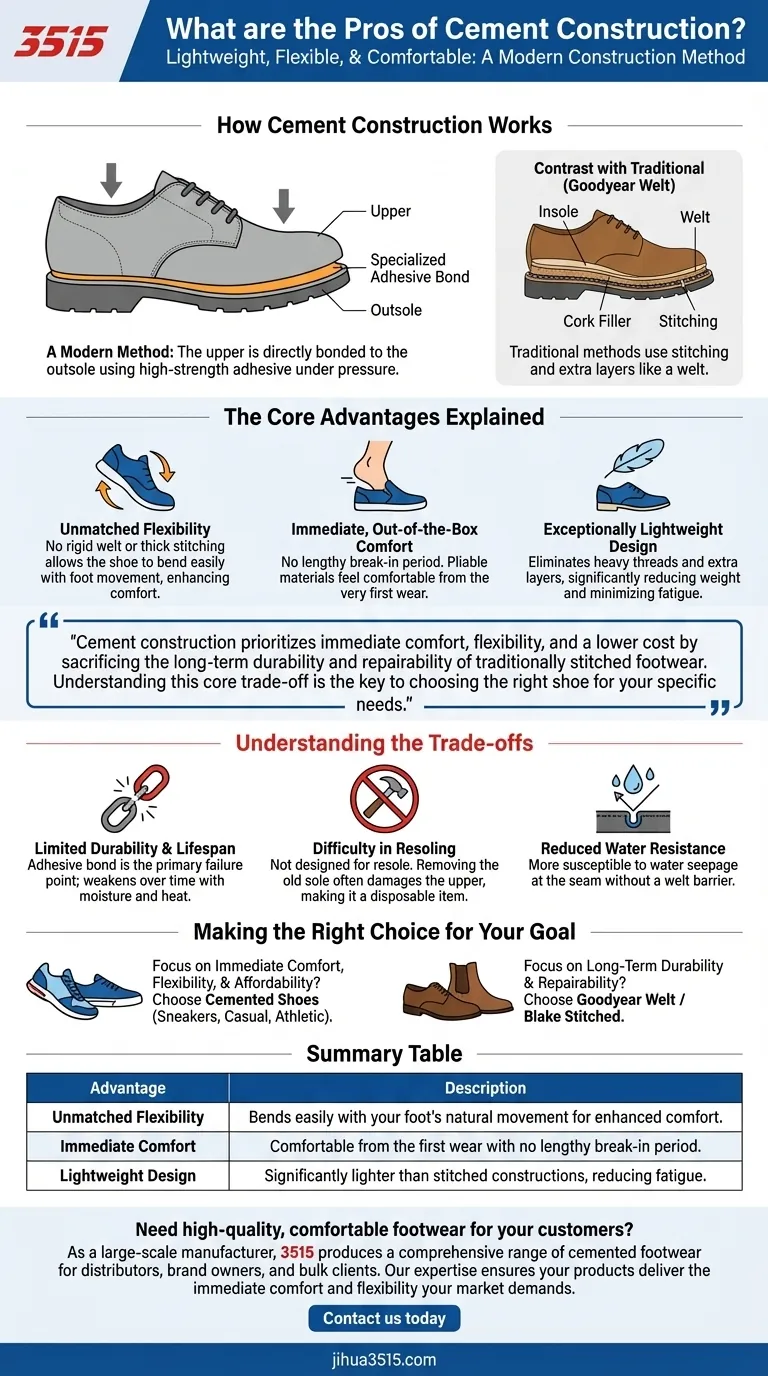

How Cement Construction Works

A Modern Method of Assembly

In its simplest form, cement construction involves applying a specialized, high-strength adhesive to bond the finished upper of the shoe directly onto the outsole. The two parts are then pressed together under high pressure to ensure a durable and lasting seal.

Contrast with Traditional Methods

This process stands in stark contrast to methods like a Goodyear welt, which uses a strip of leather (the welt) and heavy stitching to attach the upper to the sole. The absence of this extra material and stitching is what gives cemented shoes their unique characteristics.

The Core Advantages Explained

Unmatched Flexibility

Because there is no rigid welt or thick stitching locking the sole in place, a cemented shoe can bend and flex much more easily with the natural movement of your foot. This freedom of movement is a significant contributor to overall comfort.

Immediate, Out-of-the-Box Comfort

Traditional welted shoes often require a lengthy "break-in" period for the stiff leather insole and cork to mold to your foot. Cemented shoes bypass this entirely, using more pliable materials that feel comfortable from the very first wear.

Exceptionally Lightweight Design

By eliminating the welt, heavy threads, and extra layers common in other construction types, cemented shoes are significantly lighter. This reduction in weight minimizes fatigue, making them ideal for sneakers, casual shoes, and athletic footwear.

Understanding the Trade-offs

Limited Durability and Lifespan

While the adhesives used are very strong, the bond is the primary point of failure. Over time, and with exposure to significant moisture or heat, this bond can weaken, leading to the sole separating from the upper. Stitched constructions are mechanically locked together and are far more robust in the long run.

Difficulty in Resoling

This is the most critical drawback. Once the original sole on a cemented shoe wears out, it is generally not designed to be replaced. The process of removing the old sole often damages the upper, making resoling impossible or not cost-effective. The shoe is essentially a disposable item.

Reduced Water Resistance

Without a welt acting as a barrier between the upper and the outsole, cemented shoes are often more susceptible to water seeping in at the seam. While fine for dry conditions, they are less suitable for consistently wet environments compared to a well-maintained welted shoe.

Making the Right Choice for Your Goal

Ultimately, the "best" construction method depends entirely on your priorities and intended use.

- If your primary focus is immediate comfort, flexibility, and affordability: Cemented shoes are an excellent choice for casual sneakers, athletic shoes, and footwear you don't intend to be a long-term investment.

- If your primary focus is long-term durability and repairability: You should look for Goodyear welted or Blake stitched footwear, as these can be resoled multiple times and represent a better value over many years of use.

By understanding the construction, you can confidently select the shoe that perfectly balances performance with purpose.

Summary Table:

| Advantage | Description |

|---|---|

| Unmatched Flexibility | Bends easily with your foot's natural movement for enhanced comfort. |

| Immediate Comfort | Comfortable from the first wear with no lengthy break-in period. |

| Lightweight Design | Significantly lighter than stitched constructions, reducing fatigue. |

Need high-quality, comfortable footwear for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of cemented footwear for distributors, brand owners, and bulk clients. Our expertise ensures your products deliver the immediate comfort and flexibility your market demands.

Contact us today to discuss your production needs and leverage our full-scale manufacturing capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do pull-on work boots compare to other types? Choose the Right Boot for Your Job

- What makes a shoe a work shoe? Discover the Essential Features for Safety & Support

- How do IoT sensor environments contribute to the lifecycle management of industrial boots? Smart Data-Driven Safety

- How should wildland firefighter boots be broken in? A Phased Guide for Safety & Performance

- Are engineer boots the only type of boots motorcyclists wear today? Explore the Best Modern Choices

- What factors should be considered when choosing work boots? Prioritize Safety, Fit, and Durability

- What is a drawback of waterproof boots? The Hidden Cost of Trapped Sweat and Heat

- What materials are used in comfortable Western-style work boots? Unlock All-Day Comfort & Durability