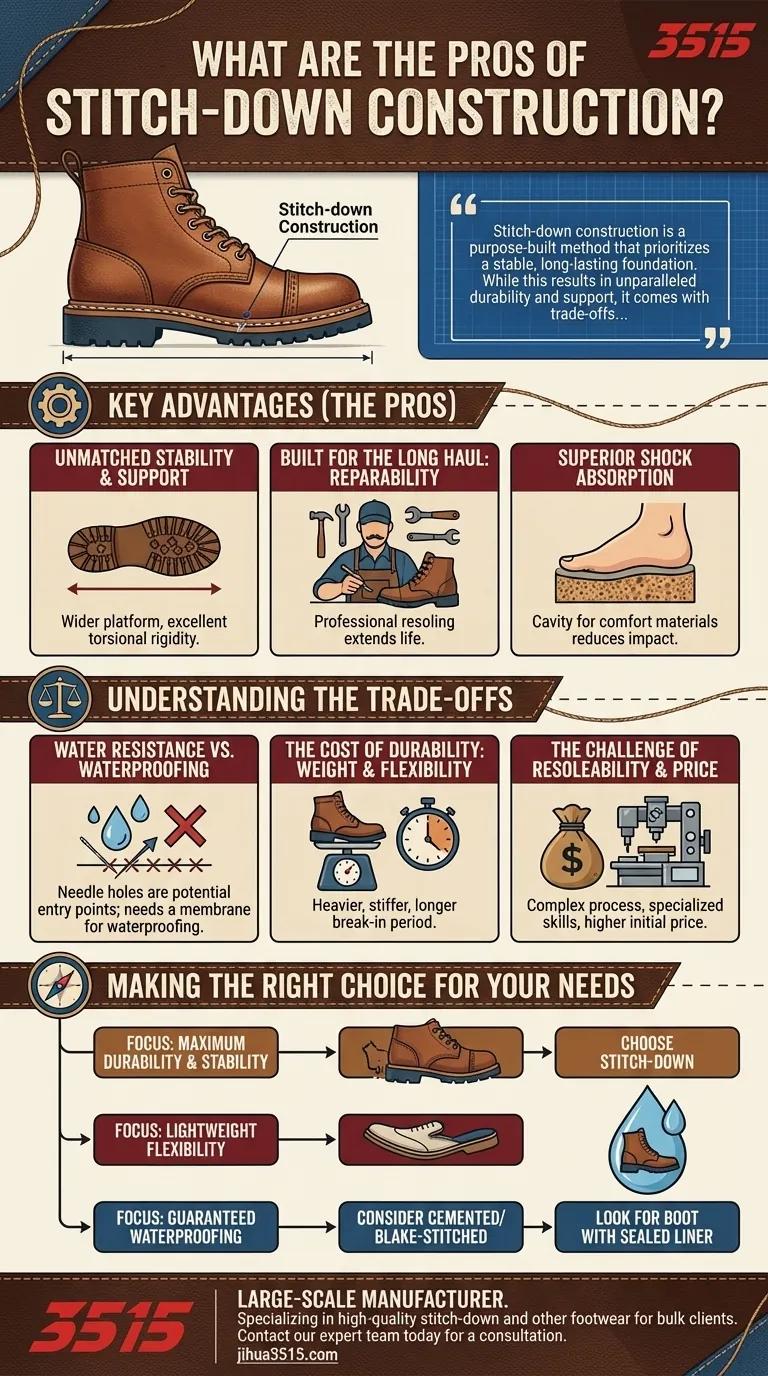

At its core, stitch-down construction offers a powerful combination of enhanced stability, long-term reparability, and effective shock absorption. This method, where the boot's upper is turned outward and stitched directly to the midsole, creates an exceptionally durable and supportive platform for your foot.

Stitch-down construction is a purpose-built method that prioritizes a stable, long-lasting foundation. While this results in unparalleled durability and support, it comes with trade-offs in weight, flexibility, and water resistance that you must consider.

A Closer Look at the Key Advantages

Stitch-down construction is not just a single feature; it's a system where each benefit reinforces the others. Understanding how these elements work together is key to appreciating its value.

Unmatched Stability and Support

The most significant advantage is the wide, stable platform it creates. By flaring the leather upper outward and stitching it to the midsole, the footprint of the boot is physically widened.

This design provides exceptional torsional rigidity, reducing the chances of your ankle rolling on uneven terrain. It's why this construction is a hallmark of high-end hiking and work boots.

Built for the Long Haul: Reparability

The external stitching is not just for stability; it’s for longevity. A skilled cobbler can cut the stitches, remove the worn-out sole, and attach a new one by re-stitching it to the same upper.

This process can dramatically extend the life of the footwear far beyond that of a cemented or glued sole, making the initial investment worthwhile over many years of use.

Superior Shock Absorption

The construction method allows for a cavity between the insole and the midsole which can be filled with shock-absorbing materials like cork or foam.

This feature significantly reduces the impact on your feet and joints during long days of walking or standing, contributing to all-day comfort.

Understanding the Trade-offs

No construction method is perfect for every situation. Being a trusted advisor means acknowledging the inherent compromises of the stitch-down method.

Water Resistance vs. Waterproofing

The hundreds of needle holes created by the stitching are potential points for water to enter. While many stitch-down boots are highly water-resistant, they are not inherently waterproof without an additional internal membrane.

The Cost of Durability: Weight and Flexibility

The robust materials and overbuilt nature of stitch-down construction result in a heavier and stiffer boot, especially when new.

This means you should anticipate a longer break-in period compared to more flexible construction methods. The initial stiffness is the price of eventual custom-molded support.

The Challenge of Resoleability

While stitch-down boots are built to be resoled, the process is complex and requires specialized skills and machinery.

Finding a cobbler who can properly perform a stitch-down resole can be more difficult and costly than resoling a more common Goodyear-welted boot.

The Impact on Price

Stitch-down construction is a labor-intensive process that requires significant hands-on skill. This craftsmanship is directly reflected in a higher initial purchase price.

Making the Right Choice for Your Needs

Selecting the right footwear construction depends entirely on your intended use and priorities.

- If your primary focus is maximum durability and stability: Stitch-down is an elite choice for demanding work, hiking, or any activity requiring a rugged and supportive platform.

- If your primary focus is lightweight flexibility: You may be better served by a cemented or Blake-stitched shoe that offers more immediate comfort and less weight.

- If your primary focus is guaranteed waterproofing: Look for a boot with a sealed, waterproof inner lining, regardless of its primary construction method.

Ultimately, choosing stitch-down construction is an investment in a stable, repairable foundation designed to last for years.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Stability & Support | Creates a wide, stable platform with excellent torsional rigidity. |

| Reparability | Allows for professional resoling, dramatically extending the boot's lifespan. |

| Shock Absorption | Cavity for materials like cork provides superior comfort and reduces joint impact. |

Need a reliable source for durable work or hiking boots?

As a large-scale manufacturer, 3515 specializes in producing high-quality stitch-down and other constructed footwear for distributors, brand owners, and bulk clients. We offer the durability and support your customers demand. Let's discuss your specific needs.

Contact our expert team today for a consultation.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- Why are PVC boots a good option for farm work? Unbeatable Chemical & Water Protection

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort

- What essential features must every fire boot provide? Ensure Total Firefighter Safety & Performance

- How do pull-on work boots compare to other types? Choose the Right Boot for Your Job

- Why is abrasion resistance important in work boots? Boost Durability & Safety for Demanding Jobs

- What are the typical features of Chelsea work boots? Unlock the Perfect Blend of Safety & Convenience

- What are the advantages of composite safety toe work boots? Lighter, Safer, and More Comfortable

- What features are often included in welted work boots for comfort? A Guide to All-Day Support