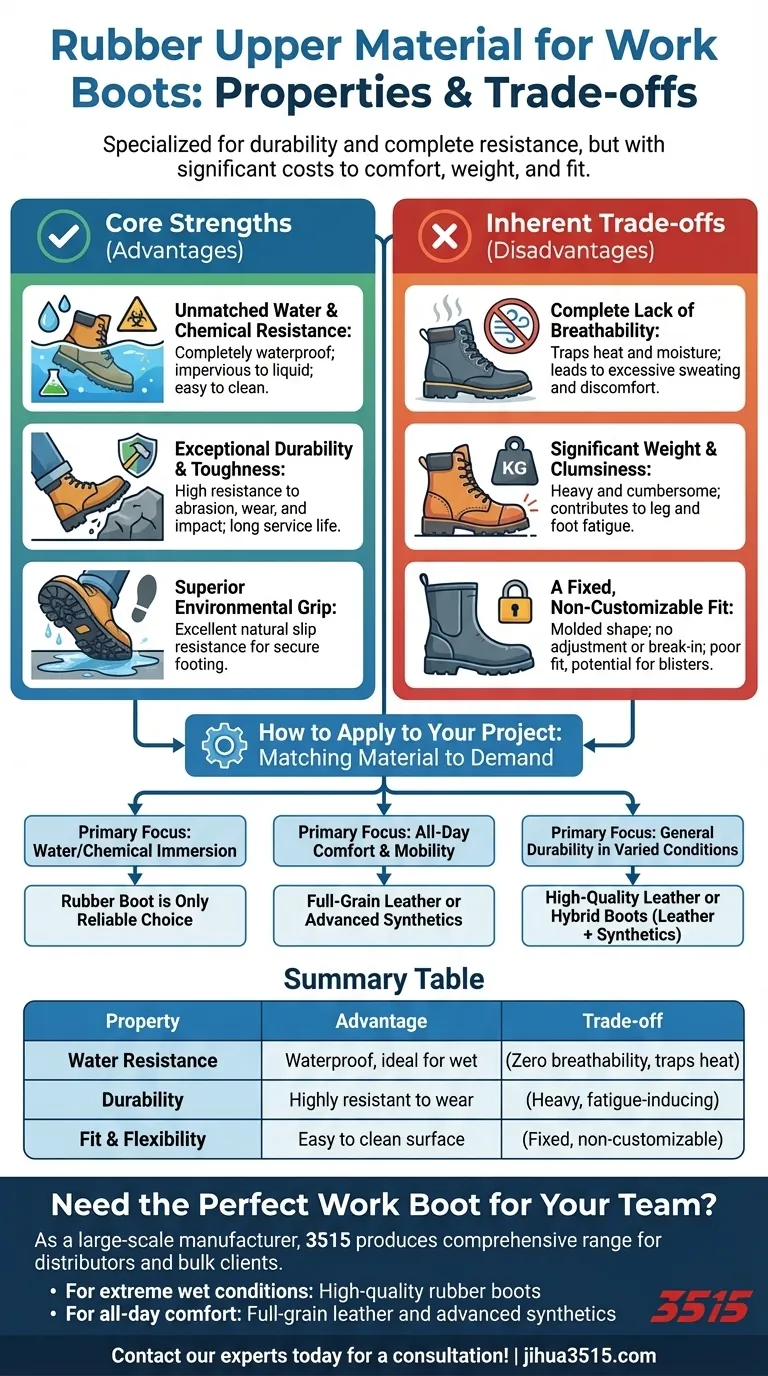

To be direct, rubber is a highly specialized upper material for work boots, prized for its exceptional durability and complete resistance to water. However, these strengths come at a significant cost to breathability, weight, and fit, which can severely impact all-day comfort and lead to fatigue.

The choice to use a rubber work boot is not about finding an all-around performer. It is a specific decision to prioritize absolute environmental protection—from water, mud, or chemicals—above all other factors like long-term comfort and mobility.

The Core Strengths of Rubber Uppers

When a job demands uncompromising protection from the elements, rubber has distinct, powerful advantages over other materials.

Unmatched Water and Chemical Resistance

The primary benefit of a rubber upper is its imperviousness to liquid. Unlike leather or synthetic fabrics that are merely "water-resistant," rubber is fully waterproof.

This makes it the ideal material for work in standing water, heavy mud, or environments where chemical splashes are a concern. The non-porous surface is also exceptionally easy to clean and decontaminate.

Exceptional Durability and Toughness

Rubber is an incredibly tough and resilient material. It is known for its high resistance to abrasion, wear, and impact.

This inherent durability means rubber boots can withstand harsh conditions and rough contact without tearing or breaking down, offering a long service life in demanding jobs.

Superior Environmental Grip

While typically a feature of the outsole, the properties of the material itself contribute to safety. Rubber naturally exhibits excellent slip resistance, providing a secure footing on wet or slick surfaces where other materials might fail.

Understanding the Inherent Trade-offs

The protective qualities of rubber create significant drawbacks that make it unsuitable for many work environments. These are not minor issues; they are fundamental limitations of the material.

A Complete Lack of Breathability

Rubber does not breathe. Its waterproof nature prevents any air exchange, trapping heat and moisture from your feet inside the boot.

This leads to excessive sweating, discomfort, and can create an environment for bacteria and odor to develop. In contrast, materials like leather allow water vapor to escape, managing temperature and moisture.

Significant Weight and Clumsiness

Compared to leather and modern synthetics like nylon, rubber is a heavy and cumbersome material.

This added weight directly contributes to leg and foot fatigue over a long workday. The inflexibility of the material can also make walking feel unnatural and strenuous.

A Fixed, Non-Customizable Fit

Rubber uppers are molded into a fixed shape and cannot be adjusted or broken in like leather. There are no laces or straps to customize the fit.

This one-size-fits-all approach often results in a poor fit, leading to chafing, blisters, and a lack of proper foot and ankle support, which is critical for preventing injury on uneven terrain.

How to Apply This to Your Project

Choosing the right boot upper is about correctly identifying your most critical need.

- If your primary focus is complete water/chemical immersion: A rubber boot is your only reliable choice for staying dry and safe.

- If your primary focus is all-day comfort and mobility: A boot made from full-grain leather or advanced synthetics will provide the necessary breathability, support, and lighter weight.

- If your primary focus is general durability in varied conditions: Look for high-quality leather or hybrid boots that combine leather with synthetic panels (like CORDURA) for a balance of toughness and breathability.

Ultimately, you must match the material's properties to the specific demands of your job.

Summary Table:

| Property | Advantage | Trade-off |

|---|---|---|

| Water Resistance | Completely waterproof, ideal for wet/muddy conditions | Zero breathability, traps heat and moisture |

| Durability | Highly abrasion and tear-resistant, long service life | Heavy and cumbersome, contributing to fatigue |

| Fit & Flexibility | Easy to clean, non-porous surface | Fixed, non-customizable fit; cannot be broken in |

| Overall Use Case | Best for absolute environmental protection (water, chemicals) | Poor choice for all-day comfort and mobility |

Need the Perfect Work Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots.

Let us help you match the right material to the job:

- For extreme wet conditions: We offer high-quality rubber boots for ultimate protection.

- For all-day comfort: We provide boots made from full-grain leather and advanced synthetics.

We ensure the right balance of safety, durability, and comfort for your specific needs.

Contact our experts today for a consultation and to discuss your project requirements!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the steps for caring for engineer boots to ensure longevity? A Guide to Decades of Wear

- What additional high-quality materials are used in Goodyear Welt boots? A Guide to Advanced Components

- What are the main characteristics of work boots? Essential Protection, Durability & Support

- Why are waterproof and breathable properties important in farming and gardening boots? The Key to All-Day Comfort and Foot Health

- What are the material compositions of PVC, neoprene, and rubber work boots? Find Your Perfect Fit

- What are the characteristics of wedge boots? Unmatched Stability and Comfort on Flat Ground

- Why is it important to keep work boots dry? Protect Your Feet and Extend Boot Life

- What is the primary function of specialized rubber safety boots in high-risk autopsies? Ensure Viral Fluid Containment