The primary advantages of composite safety toe boots are their lighter weight, their inability to conduct electricity, and their non-metallic nature, which prevents them from triggering metal detectors. These characteristics make them superior to steel toe boots for specific work environments, particularly those involving electrical hazards, security checkpoints, or extreme temperatures.

While both steel and composite toe boots are engineered to meet the same official safety standards, the best choice depends entirely on your specific work environment. Composite toes excel in comfort and electrical safety, while steel provides the highest possible resistance to extreme impacts.

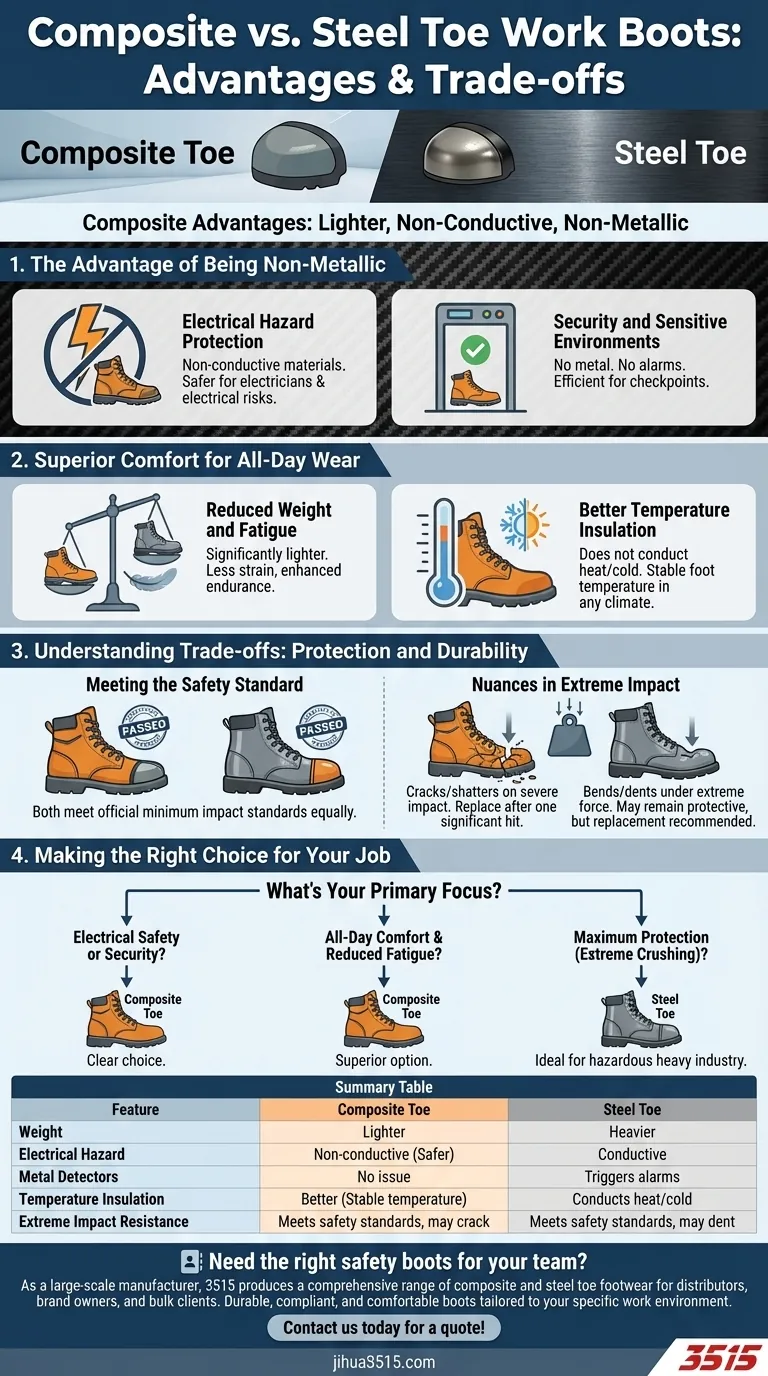

The Advantage of Being Non-Metallic

The core of the composite toe's benefits stems from its construction using materials like carbon fiber, Kevlar, and specialized plastics. This complete lack of metal creates distinct safety and convenience advantages.

Electrical Hazard Protection

Because they are made from non-conductive materials, composite toe boots are the default choice for electricians or anyone working in environments with a risk of electrical shock. They provide a critical layer of protection that steel, a natural conductor, cannot offer.

Security and Sensitive Environments

For professionals who must frequently pass through metal detectors, such as those in security, logistics, or at certain government and industrial sites, composite toes are a practical necessity. They eliminate the daily inconvenience of removing footwear for security screenings.

Superior Comfort for All-Day Wear

Beyond environmental safety, composite materials offer significant ergonomic benefits that directly impact comfort and productivity over a long shift.

Reduced Weight and Fatigue

Composite toe caps are significantly lighter than their steel counterparts. This reduction in weight, though seemingly small, translates to less fatigue and strain on your legs and feet over thousands of steps, enhancing comfort and endurance during long workdays.

Better Temperature Insulation

Metal is a highly efficient thermal conductor, meaning steel toes can become uncomfortably cold in winter and hot in summer. Composite materials do not conduct temperature effectively, providing far better insulation and helping maintain a stable, comfortable foot temperature in any climate.

Understanding the Trade-offs: Protection and Durability

While composite toes offer many advantages, it's crucial to understand the nuances of their protective capabilities compared to steel.

Meeting the Safety Standard

Both composite and steel toe boots sold for safety purposes must meet the same minimum impact and compression resistance standards set by organizations like ASTM International (e.g., F2413-18). For the officially rated level of protection, both are equally safe.

Nuances in Extreme Impact

The key difference lies in how they perform under impacts that exceed the safety standard. Steel has a higher ultimate strength and will tend to bend or dent under extreme force. Composite materials, while strong, can crack or shatter upon a severe impact that compromises their structure.

After a significant impact, a composite toe boot must be replaced. A steel toe might remain protective even with a dent, although replacement is always the safest course of action for any compromised safety footwear.

Making the Right Choice for Your Job

Your specific daily tasks and environment should be the deciding factor.

- If your primary focus is electrical safety or passing through metal detectors: Composite toe boots are the clear and necessary choice.

- If your primary focus is all-day comfort and reducing fatigue: The lighter weight and thermal insulation of composite boots make them a superior option.

- If your primary focus is maximum protection against extreme crushing forces: Steel toe boots offer the highest possible level of impact resistance, making them ideal for the most hazardous heavy-industry environments.

Ultimately, choosing the right safety boot is about matching the tool to the specific demands of your profession.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Weight | Lighter | Heavier |

| Electrical Hazard | Non-conductive (Safer) | Conductive |

| Metal Detectors | No issue | Triggers alarms |

| Temperature Insulation | Better (Stable temperature) | Conducts heat/cold |

| Extreme Impact Resistance | Meets safety standards, may crack | Meets safety standards, may dent |

Need the right safety boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of composite and steel toe footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant, and comfortable boots tailored to your specific work environment. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- Why are high quality leather linings important for boots? Enhance Comfort, Durability & Foot Health

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- What are common mistakes to avoid when maintaining work boots? Protect Your Investment & Safety

- What are the key characteristics of western work boots? The Ultimate Guide to Style & Safety

- What factors should be considered when choosing the right toe cap for work boots? Find Your Perfect Fit for Safety & Comfort

- How long do heavy duty work boots typically last? Extend Their Life to 3+ Years

- What maintenance practices extend the lifespan of work boots? A Proactive Care System for Maximum Durability

- What additional safety features can be found in Chemical Resistant boots? Essential Multi-Hazard Protection