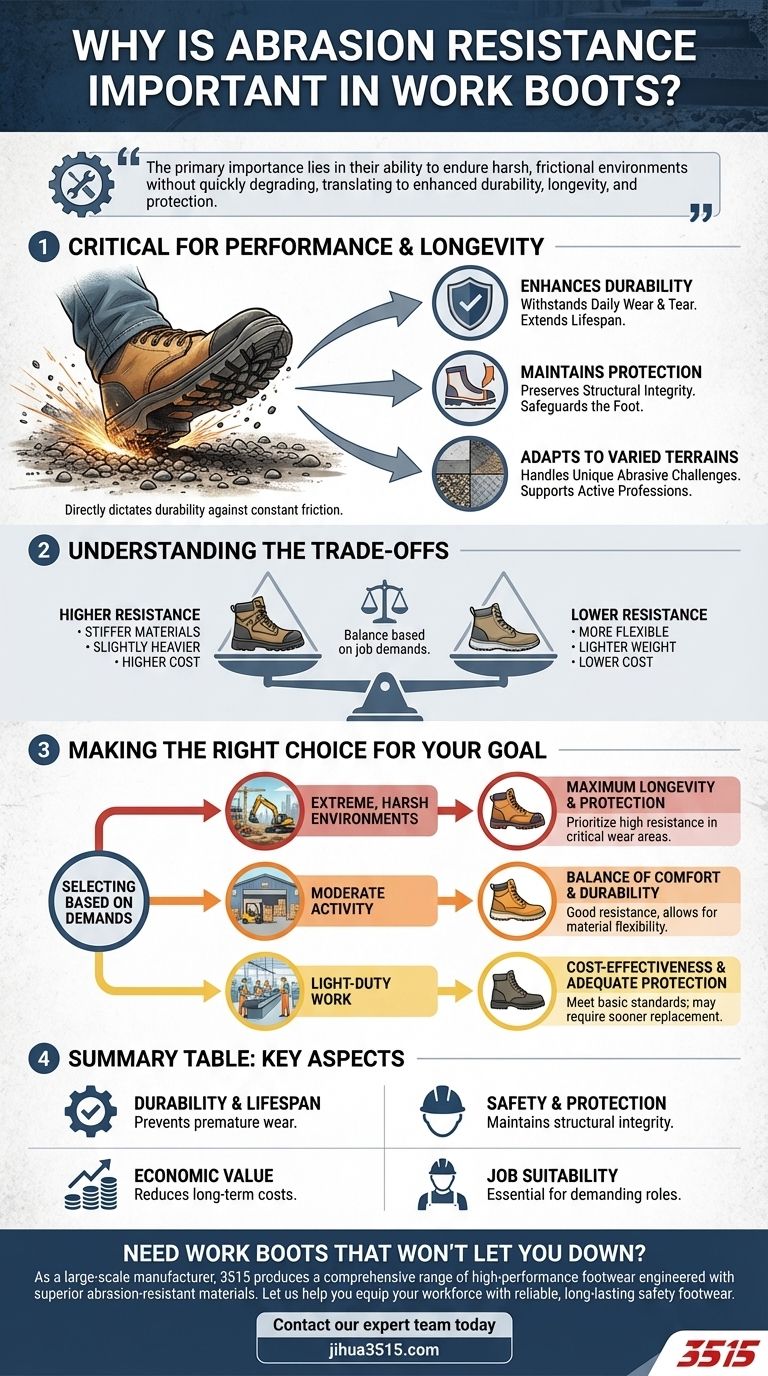

Abrasion resistance is vital in work boots because it directly dictates their durability and protective capabilities against daily wear and tear from constant friction. It ensures the boots can withstand repeated scraping and rubbing against various harsh surfaces encountered in demanding work environments, thus extending their lifespan and maintaining their structural integrity. This resilience is fundamental for both economic longevity and wearer safety.

The primary importance of abrasion resistance in work boots lies in their ability to endure harsh, frictional environments without quickly degrading. This characteristic directly translates into enhanced durability, longevity, and protection for the wearer against the physical demands of various terrains and job site hazards.

Why Abrasion Resistance is a Critical Work Boot Feature

Work boots are subjected to significant stress, and abrasion resistance is a key factor in how well they perform and last. This property ensures the boot materials can withstand the constant friction from various surfaces.

Enhancing Durability and Lifespan

Withstanding Daily Wear and Tear Work boots with good abrasion resistance are designed to endure the constant rubbing and scraping that occurs during daily use. This includes walking across concrete, gravel, dirt, and other abrasive surfaces.

Protecting Against Material Degradation The inherent toughness of abrasion-resistant materials prevents them from quickly wearing thin, tearing, or developing holes. This directly contributes to the boot's overall durability and extends its usable life.

Maintaining Protective Qualities

Preserving Structural Integrity Abrasion resistance helps maintain the boot's outer shell and internal protective layers, ensuring they remain effective against impacts or punctures. If the outer material wears through, the boot's protective features are compromised.

Safeguarding the Foot In environments where friction can cause damage (e.g., dragging feet, rubbing against machinery), abrasion-resistant materials prevent direct exposure to the foot. This minimizes risks of cuts, scrapes, or other injuries that could occur if the boot material failed.

Relevance Across Work Environments

Adapting to Varied Terrains Workers who traverse diverse surfaces—from rough construction sites to factory floors—benefit significantly from abrasion-resistant boots. The boots are better equipped to handle the unique abrasive challenges of each environment.

Supporting Active Professions For professionals who are constantly on their feet, walking, climbing, or kneeling, abrasion resistance is paramount. It ensures the boots can keep up with the physical demands without premature degradation.

Understanding the Trade-offs

While highly beneficial, maximizing abrasion resistance can involve certain considerations that impact other boot characteristics.

Material Properties and Flexibility

Stiffer Materials for High Resistance Materials engineered for high abrasion resistance are often denser and less flexible than other options. This can sometimes lead to a slightly stiffer boot, impacting initial comfort or break-in time.

Weight Implications Very robust, abrasion-resistant materials might add a marginal amount of weight to the boot. This is a trade-off for enhanced durability and protection.

Cost Considerations

Higher Quality, Higher Price Boots featuring advanced abrasion-resistant materials and construction techniques typically come at a higher price point. This investment usually pays off in extended longevity and fewer replacement costs.

Making the Right Choice for Your Goal

Selecting work boots with appropriate abrasion resistance depends on your specific job demands and priorities.

- If your primary focus is maximum longevity and protection in extremely harsh, abrasive environments: Prioritize boots with high abrasion resistance ratings, particularly in critical wear areas like the sole and toe.

- If your primary focus is a balance of comfort and reasonable durability for moderate activity: Look for boots that specify good abrasion resistance without necessarily being the absolute highest grade, allowing for more material flexibility.

- If your primary focus is cost-effectiveness with adequate protection for light-duty work: Choose boots that meet basic abrasion resistance standards, understanding they might require replacement sooner under heavier use.

Investing in work boots with strong abrasion resistance is a strategic decision that enhances safety, extends product life, and offers long-term value for demanding professions.

Summary Table:

| Key Aspect | Why It Matters for Work Boots |

|---|---|

| Durability & Lifespan | Withstands daily scraping and rubbing, preventing premature wear and tear. |

| Safety & Protection | Maintains the boot's structural integrity, safeguarding feet from cuts and impacts. |

| Economic Value | Reduces long-term costs by extending the boot's usable life, minimizing replacements. |

| Job Suitability | Essential for demanding professions like construction, manufacturing, and warehousing. |

Need work boots that won't let you down?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear built to last. Our boots are engineered with superior abrasion-resistant materials to provide unmatched durability and protection for distributors, brand owners, and bulk clients in the most demanding work environments.

Let us help you equip your workforce with reliable, long-lasting safety footwear.

Contact our expert team today to discuss your specific needs and discover how our production capabilities can deliver the perfect solution for your business.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do social media interactivity features enhance procurement engagement for tactical and work boots?

- How are boots designed to meet the ASTM standard for electrical hazard protection?

- What were the original purposes of cowboy boots? A Tool for Safety and Function on the Range

- What is the difference between traditional cowboy boots and roper boots? Choose the Right Boot for Your Needs

- What are the key elements of a Smart-Casual Weekend Look with moc toe boots? Master the Polished, Relaxed Style

- What are logger or packer boots used for? Essential Gear for Uneven Terrain Work

- How can you freshen smelly work boots? A Permanent Guide to Eliminating Odor

- What are the steps for caring for engineer boots to ensure longevity? A Guide to Decades of Wear