At their core, composite toe boots offer modern safety protection without the traditional drawbacks of metal. The primary benefits are a significantly lighter weight for reduced foot fatigue, natural insulation against extreme temperatures, and a non-metallic construction that makes them ideal for electricians and workers in high-security, metal-free environments.

The key advantage of composite toe technology is not just protection, but specialized performance. It delivers ASTM-certified safety in a package that is lighter, more comfortable in varied climates, and inherently safer around electrical hazards than its steel counterpart.

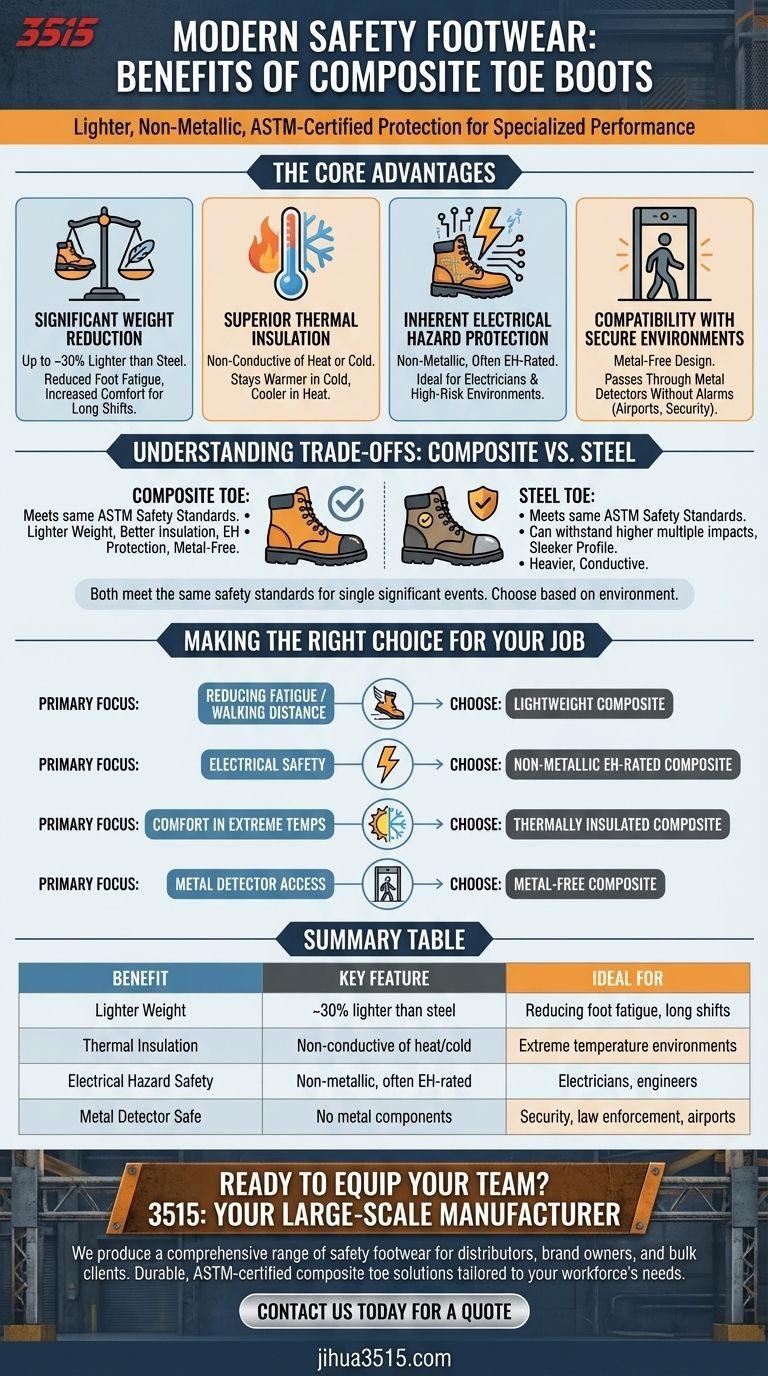

The Core Advantages of Composite Toe Technology

Composite toe caps are engineered from non-metal materials like Kevlar, carbon fiber, plastic, or fiberglass. This fundamental difference from steel is the source of their unique benefits.

Significant Weight Reduction

The most immediate benefit is a noticeable reduction in boot weight. Composite materials are often around 30% lighter than steel while still meeting the same safety standards.

This weight difference translates directly to less strain on your legs and feet over a long workday, reducing overall fatigue and increasing comfort.

Superior Thermal Insulation

Unlike metal, composite materials do not readily conduct heat or cold. This provides a significant comfort advantage for anyone working outdoors or in environments with extreme temperatures.

Your feet will stay warmer in the cold and cooler in the heat, as the protective cap won't transfer the ambient temperature to your toes.

Inherent Electrical Hazard Protection

Because they contain no metal, composite toe boots are non-conductive. This makes them the default choice for electricians, engineers, and anyone working in roles with a risk of electrical shock.

Many of these boots carry an Electrical Hazard (EH) rating, certifying they provide a secondary source of protection against live circuits.

Compatibility with Secure Environments

The metal-free design allows you to pass through metal detectors without setting them off. This is a critical advantage for professionals in fields like law enforcement, corrections, or those working at airports and secure facilities.

Understanding the Trade-offs: Composite vs. Steel

While the benefits are clear, choosing the right boot requires understanding the complete picture. No single material is perfect for every situation.

Impact and Compression Resistance

Both composite and steel toe boots must meet the same ASTM safety standards for impact and compression. They are both tested to protect you from a single, significant event.

However, steel can often withstand higher forces beyond the standard and may handle multiple impacts better before failing. After a major impact, any safety toe boot should be replaced.

The Profile of the Boot

To achieve the same level of protection as steel, a composite toe cap may need to be slightly thicker or bulkier. This can sometimes affect the overall profile and fit of the boot compared to a sleeker steel toe model.

Making the Right Choice for Your Job

Your specific work environment and daily tasks should be the deciding factor.

- If your primary focus is reducing fatigue or you walk long distances: The lightweight nature of composite toe boots is the superior choice for all-day comfort.

- If your primary focus is electrical safety: You must choose a non-metallic composite toe boot, preferably one with an explicit EH rating.

- If your primary focus is comfort in extreme hot or cold temperatures: The thermal insulation of composite offers a significant advantage over conductive steel.

- If you frequently pass through metal detectors for your job: A composite toe boot will eliminate a major daily inconvenience.

Ultimately, choosing a composite toe boot is a decision for modern, lightweight protection tailored to specific environmental and electrical risks.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Lighter Weight | ~30% lighter than steel | Reducing foot fatigue, long shifts |

| Thermal Insulation | Non-conductive of heat/cold | Extreme temperature environments |

| Electrical Hazard Safety | Non-metallic, often EH-rated | Electricians, engineers |

| Metal Detector Safe | No metal components | Security, law enforcement, airports |

Ready to equip your team with high-performance composite toe boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite toe shoes and boots, ensuring durable, ASTM-certified protection tailored to your workforce's needs.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What features should one look for in wildland firefighter boots? Critical NFPA 1977 Safety Elements

- What industries benefit most from soft-toe boots? Prioritize Comfort and Agility for Your Workforce

- What advancements have been made in soft-toe boot design? From Durability to All-Day Comfort

- What are the advantages of using Rubber for work boots? Unbeatable Safety & Durability

- What are some frequently asked questions about engineer boots? Get the Complete Guide to Fit, Style & Purpose

- What are work boots designed for? Ultimate Protection, Support & Durability

- What are moc toe boots known for? Unmatched Durability, Comfort & Timeless Style

- What is the significance of waterproof and breathable properties in work footwear? Boost Safety in Wet Conditions