At their core, work boots are purpose-built tools for your feet. They are a critical piece of personal protective equipment (PPE) designed specifically to provide uncompromising protection, all-day support, and long-term durability for individuals working in hazardous or demanding environments like construction sites, factories, and logging operations.

The fundamental design purpose of a work boot is to mitigate specific, predictable workplace hazards. Unlike casual footwear, every feature—from the sole's tread to the height of the collar—is engineered to counter risks like impact, puncture, electrical shock, and unstable terrain.

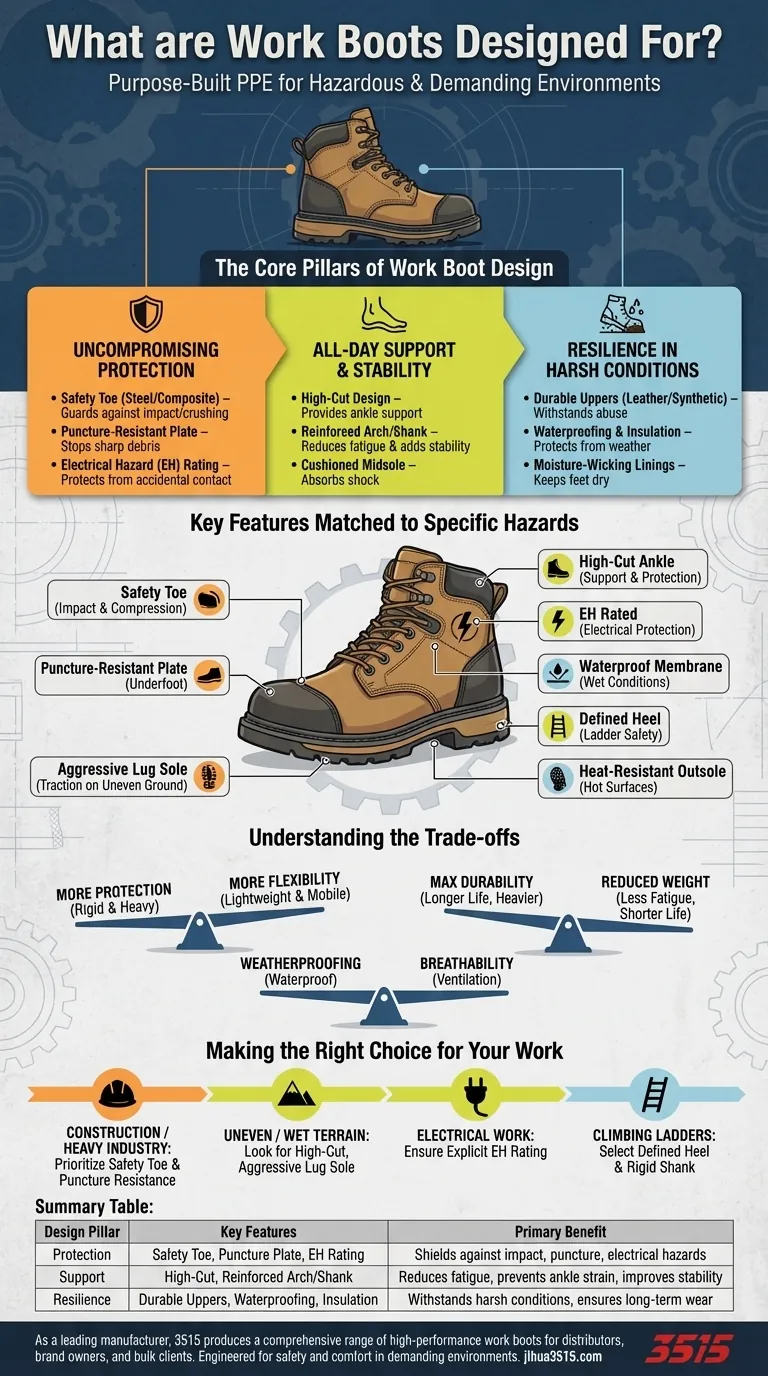

The Core Pillars of Work Boot Design

To understand a work boot, you must first understand the three principles that guide its construction: protection, support, and resilience.

Uncompromising Protection

This is the most critical function. Work boots are designed to be a shield against immediate and serious threats that are common in manual labor and industrial settings.

This protection includes features like steel or composite safety toes to guard against crushing injuries from falling objects and puncture-resistant plates in the sole to stop nails or sharp debris.

Many are also rated for Electrical Hazard (EH) resistance, providing a secondary source of protection against accidental contact with live electrical circuits.

All-Day Support and Stability

Workers are on their feet for hours, often on hard or uneven surfaces. Work boots are engineered to reduce fatigue and prevent musculoskeletal strain.

The characteristic high-cut design provides crucial ankle support, helping to prevent twists and sprains on rough ground.

A reinforced arch or shank is often built into the midsole. This feature provides stability, especially for those who frequently climb ladders or stand on rungs.

Resilience in Harsh Conditions

Work boots are built to withstand abuse that would destroy conventional shoes. Their construction emphasizes longevity and performance in challenging weather.

Uppers are typically made from durable, moisture-resistant materials like leather. Inside, moisture-wicking linings help manage sweat to keep feet dry and prevent blisters.

For outdoor work, many boots offer full waterproofing and thermal insulation to protect against rain, snow, and cold-weather health risks like frostbite.

Key Features Matched to Specific Hazards

The effectiveness of a work boot comes from its specific features, each engineered to solve a particular problem.

The Outsole: Your Connection to the Ground

The sole is arguably the most specialized component. Its design is directly tied to the work environment.

A deep, aggressive tread pattern (lug sole) is essential for traction on mud, gravel, or other loose, uneven surfaces. In contrast, a shallower pattern provides better slip resistance on smooth concrete or warehouse floors.

A defined heel is a non-negotiable feature for anyone using ladders, as it helps lock the boot onto the rung and prevent slips.

For jobs like road paving, outsoles must be heat-resistant to prevent melting when exposed to hot surfaces, with some rated up to 572ºF.

Understanding the Trade-offs

No single boot is perfect for every job. The design of a work boot always involves balancing competing priorities.

Protection vs. Flexibility

The more protective a boot is—with thick leather, a steel toe, and a puncture plate—the more rigid and heavy it becomes.

This is why a logger's boot is incredibly tough but not ideal for running. In contrast, a tactical or duty boot for law enforcement sacrifices some heavy-duty protection for the flexibility needed to run and move quickly.

Durability vs. Weight

The most durable materials and construction methods, like a Goodyear welt, add significant weight to the boot.

While this ensures a long service life, the added weight can contribute to foot fatigue over a long shift. Lighter-duty boots may be more comfortable but will not last as long under intense use.

Weatherproofing vs. Breathability

A fully waterproof membrane is excellent at keeping water out, but it can also limit the boot's ability to release hot, moist air from sweat.

In hot and dry climates, a highly waterproof boot can lead to uncomfortably warm feet. In these cases, a non-waterproof boot made of breathable materials might be a better choice.

Making the Right Choice for Your Work

Selecting the right boot means matching its design features to the specific hazards of your job.

- If your primary focus is construction or heavy industry: Prioritize a certified safety toe (steel or composite) and puncture resistance to protect against impact and sharp objects.

- If your primary focus is working on uneven or wet terrain: Look for a boot with a high-cut design for ankle support and an aggressive lug sole for maximum traction.

- If your primary focus is electrical work: Ensure your boot has an explicit Electrical Hazard (EH) rating to provide a necessary layer of protection.

- If your primary focus is climbing ladders or scaffolding: Select a boot with a defined heel and a rigid, supportive shank for stability and comfort.

Ultimately, a work boot is an essential investment in your personal safety and daily comfort on the job.

Summary Table:

| Design Pillar | Key Features | Primary Benefit |

|---|---|---|

| Protection | Safety toe (steel/composite), Puncture-resistant plate, EH rating | Shields against impact, puncture, electrical hazards |

| Support | High-cut ankle design, Reinforced arch/shank | Reduces fatigue, prevents ankle strain, improves stability |

| Resilience | Durable leather uppers, Waterproofing, Insulation | Withstands harsh conditions, ensures long-term wear |

As a leading manufacturer, 3515 produces a comprehensive range of high-performance work boots for distributors, brand owners, and bulk clients. Our footwear is engineered to meet the exacting demands of construction, industrial, and outdoor work environments, combining certified safety features with all-day comfort.

Ready to equip your workforce with durable, purpose-built footwear? Contact 3515 today to discuss your specific needs and explore our full production capabilities.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why is the anti-smash feature essential in palm oil processing areas? Ensure Worker Safety from Heavy Machinery Risks

- What primary protective functions do industrial safety shoes provide? Maximize Safety in Heavy Machinery Maintenance