Engineer boots are defined by their iconic laceless, pull-on design featuring a tall shaft, a plain toe, and distinctive adjustment buckles. The most frequently asked questions revolve around their specific purpose, how they should fit, the materials they are made from, and how to style them effectively for work, motorcycling, or casual wear.

Engineer boots are more than just footwear; they are a statement of durability and heritage. Their value comes from a rugged, laceless construction designed for protection, but this same feature demands careful consideration of both fit and styling to be worn correctly.

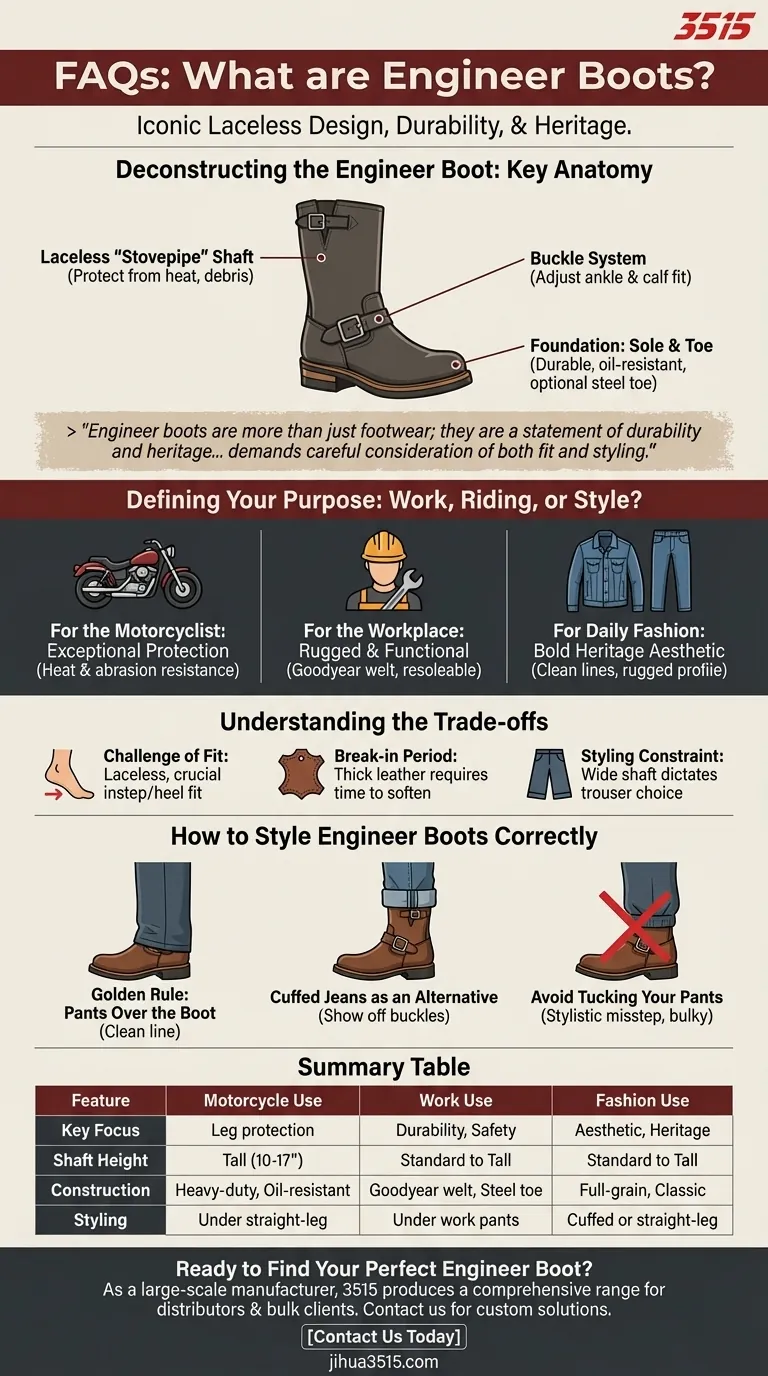

Deconstructing the Engineer Boot: Key Anatomy

To understand the function of an engineer boot, you must first understand its core components. Each element serves a specific, practical purpose that has evolved from its origins as industrial workwear.

The Laceless "Stovepipe" Shaft

The most recognizable feature is the tall, unstructured leather shaft, often called a "stovepipe." Ranging from 7 to 17 inches, its primary purpose is to protect the leg from heat, debris, and abrasion.

The Buckle System

Instead of laces, engineer boots use two adjustable leather straps with metal buckles. One is positioned over the instep to secure the ankle, while the second is at the top of the shaft to make minor adjustments to the fit around the calf.

The Foundation: Sole and Toe

These boots are built on a foundation of durability. They typically feature thick, oil-resistant soles for grip and longevity. The classic design includes a plain, unstructured toe, though many work-oriented models include a reinforced steel toe for safety.

Defining Your Purpose: Work, Riding, or Style?

The right boot for you depends entirely on its intended use. While all engineer boots share a common design heritage, their specifications can vary significantly.

For the Motorcyclist

Motorcyclists favor these boots for their exceptional protection. The tall, thick leather shaft shields the rider's legs from engine heat and road debris, while the heavy-duty construction provides abrasion resistance.

For the Workplace

Originating as work boots, they remain a practical choice for industrial environments. Their rugged build, pull-on convenience, and protective features make them highly functional. Look for Goodyear welt construction, which allows the boot to be resoled.

For Daily Fashion

As a style piece, the engineer boot offers a bold, classic aesthetic rooted in American heritage. Its clean lines and rugged profile make a strong statement, pairing well with denim and other durable fabrics.

Understanding the Trade-offs

The unique design of the engineer boot presents a distinct set of challenges that are critical to understand before making a purchase.

The Challenge of Fit

The laceless design means the initial fit is paramount. Unlike a lace-up boot, you have very little ability to adjust how it holds your foot. A proper fit around the instep and heel is non-negotiable to prevent excessive slippage.

The Break-in Period

High-quality engineer boots use thick, full-grain leather. This material requires a significant break-in period to soften and conform to the shape of your foot. This process can be uncomfortable at first but results in a truly custom fit.

The Styling Constraint

The wide shaft fundamentally dictates your choice of trousers. These boots are designed to be worn under your pants, meaning they are incompatible with slim or tapered-fit jeans.

How to Style Engineer Boots Correctly

Wearing engineer boots effectively is about respecting their silhouette. There are established conventions that work with the boot's design, not against it.

The Golden Rule: Pants Over the Boot

The classic and most effective method is to wear straight-leg or boot-cut pants that fit comfortably over the boot's shaft. This balances the boot's visual weight and creates a clean, uninterrupted line from the leg down.

Cuffed Jeans as an Alternative

If you want to show off the boot's buckles, the best approach is to cuff your jeans to a higher inseam. This allows the top of the boot to be seen without violating the primary rule of not tucking.

Avoid Tucking Your Pants

Tucking your pants into engineer boots is generally considered a stylistic misstep. It disrupts the silhouette, adds unnecessary bulk, and works against the boot's intended ruggedly understated aesthetic.

Making the Right Choice for Your Goal

Your primary use case should be the single most important factor in your decision.

- If your primary focus is motorcycle riding: Prioritize a tall, sturdy shaft, thick full-grain leather, and an oil-resistant sole for maximum protection and durability.

- If your primary focus is work or industrial use: Look for Goodyear welt construction for resoling capability and consider a steel toe if your environment requires it.

- If your primary focus is fashion and daily wear: Concentrate on the specific leather finish, toe shape, and overall silhouette that best integrates with your personal style.

Choosing the right engineer boot is about aligning its uncompromising design with your specific purpose.

Summary Table:

| Feature | Motorcycle Use | Work Use | Fashion Use |

|---|---|---|---|

| Key Focus | Leg protection, abrasion resistance | Durability, resoling, safety | Aesthetic, heritage style |

| Shaft Height | Tall (10-17 inches) | Standard to Tall | Standard to Tall |

| Construction | Heavy-duty leather, oil-resistant sole | Goodyear welt, steel toe option | Full-grain leather, classic design |

| Styling | Worn under straight-leg pants | Worn under work pants | Cuffed or straight-leg jeans |

Ready to Find Your Perfect Engineer Boot?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable engineer boots for distributors, brand owners, and bulk clients. Whether you need high-protection boots for motorcycling, rugged work boots for industrial use, or stylish heritage footwear, our production capabilities ensure top quality and custom solutions.

Contact us today to discuss your specific requirements and benefit from our expert manufacturing experience.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What materials are typically used for the outsole of light work boots? Find the Perfect Balance of Durability & Comfort

- How do EH-rated work boots protect against electrical hazards? Insulate Against Shock with Certified Safety

- What are the temperature ratings and recommended uses for 400g insulated boots? Your Guide to Winter Warmth

- What workplace hazards do safety toe boots protect against? Comprehensive Protection Guide

- What are the benefits of nylon and synthetic fibers in firefighter boots? Boost Endurance & Foot Safety

- Why is proper fit crucial for fire boot protection? The Key to Safety and Performance

- What features should workers exposed to chemicals look for in work boots? Essential Guide for Safety

- How should work boots be stored? Protect Your Investment with Proper Storage