The most critical features in a wildland firefighter boot are a heat-resistant lug sole that provides traction without melting, a durable upper made of thick, high-quality leather, and fire-resistant stitching that holds the boot together under extreme stress. These elements are non-negotiable for safety and performance on the fireline.

A wildland boot is not merely footwear; it is a critical piece of personal protective equipment. The right choice goes beyond a simple feature checklist to balance the absolute requirements of heat resistance and durability against the specific demands of your terrain and the need for long-term comfort.

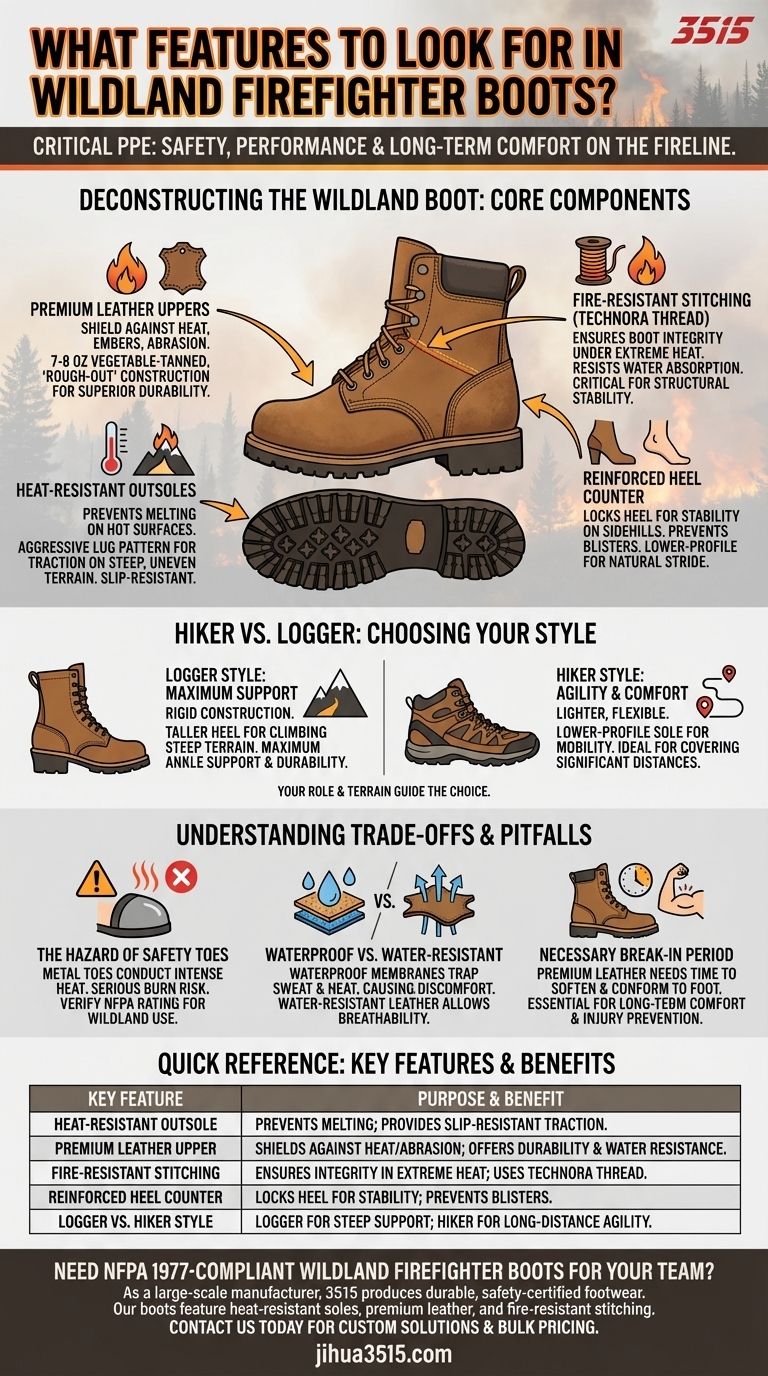

Deconstructing the Wildland Boot: Core Components

Understanding the purpose behind each component is key to selecting a boot that will protect you when it matters most. These boots are engineered systems where every material serves a vital function.

The Foundation: Heat-Resistant Outsoles

The outsole is your primary point of contact with the hazardous ground. It must be made from a specialized, heat-resistant rubber compound that will not melt, deform, or delaminate when exposed to hot ash and embers.

A deep, aggressive lug pattern is essential for maintaining stable footing on steep, uneven, and loose terrain, from rock to mud. This slip-resistant design is a fundamental safety feature.

The Shield: Premium Leather Uppers

The boot's upper must act as a shield against heat, embers, and sharp objects. The standard is thick, seven-ounce or eight-ounce hide, typically vegetable-tanned leather, prized for its superior stiffness and durability.

Many wildland boots use a "rough-out" leather construction, where the rougher side of the hide faces out. This design is more resistant to abrasion and is thought to help with cooling.

The Seams: Fire-Resistant Stitching

The thread holding a boot together can be its weakest point. Wildland boots must use fire-resistant stitching, such as Technora thread, which remains stable at extreme temperatures and resists water absorption. Standard threads would quickly fail, causing the boot to fall apart.

The Structure: Support and Stability

A reinforced heel counter is crucial for locking your heel in place, preventing blisters and providing stability on sidehills. Unlike structural firefighting or standard work boots, wildland boots often feature a lower-profile heel to facilitate a more natural stride when walking long distances over varied terrain.

Hiker vs. Logger: Choosing Your Style

Wildland boots generally fall into two design categories, each offering a different balance of support and mobility.

The Logger Style: Maximum Support

The traditional logger boot is defined by its taller, pronounced heel designed to aid in climbing steep terrain. This style typically offers a more rigid construction, providing maximum ankle support and durability in the most rugged conditions.

The Hiker Style: Agility and Comfort

Drawing inspiration from modern hiking footwear, this style is lighter and more flexible. With a lower-profile sole and athletic-inspired design, the hiker style prioritizes comfort and agility for firefighters who cover significant distances on foot.

Understanding the Trade-offs and Pitfalls

Making the right choice involves understanding not just what to look for, but also what to be wary of.

The Hazard of Safety Toes

While steel or composite safety toes are standard in many work boots, they can be a significant hazard in wildland firefighting. Metal toes can conduct and retain intense heat, creating a serious burn risk. Always verify that any toe protection is specifically rated for wildland fire use under NFPA standards.

"Waterproof" vs. Water-Resistant

True waterproof membranes, while great for keeping water out, can also trap sweat and heat inside the boot. In the hot, strenuous environment of a wildfire, this can lead to severe discomfort and blisters. A high-quality, oil-tanned leather upper provides excellent water resistance while still allowing the boot to breathe.

The Necessity of a Break-In Period

Do not expect a top-tier leather wildland boot to be perfectly comfortable out of the box. The durable, thick leather requires a break-in period to soften and conform to the unique shape of your foot. This initial investment of time is critical for achieving long-term comfort and preventing injury on the line.

Making the Right Choice for Your Role

Your specific role and typical environment should guide your final decision.

- If your primary focus is working on steep, rugged terrain: The rigid support and pronounced heel of a traditional logger-style boot offer the best stability.

- If your primary focus is mobility and covering long distances: A modern hiker-style boot provides superior flexibility and reduces fatigue over many miles.

- If your primary focus is compliance and safety: Always start by ensuring the boot is certified to the current NFPA 1977 standard for wildland firefighting protective clothing and equipment.

Choosing the right boot is a critical investment in your safety, endurance, and overall effectiveness on the fireline.

Summary Table:

| Key Feature | Purpose & Benefit |

|---|---|

| Heat-Resistant Outsole | Prevents melting on hot surfaces; provides slip-resistant traction. |

| Premium Leather Upper | Shields against heat and abrasion; offers durability and water resistance. |

| Fire-Resistant Stitching | Ensures boot integrity under extreme heat; uses Technora thread. |

| Reinforced Heel Counter | Locks heel in place for stability on uneven terrain; prevents blisters. |

| Logger vs. Hiker Style | Logger for steep terrain support; Hiker for long-distance agility. |

Need NFPA 1977-compliant wildland firefighter boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-certified footwear for distributors, brand owners, and bulk clients. Our boots are engineered with heat-resistant soles, premium leather uppers, and fire-resistant stitching to protect firefighters in the most demanding conditions.

Contact us today to discuss custom solutions and bulk pricing tailored to your needs.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What features should HVAC technicians look for in work boots? Find the Perfect Blend of Safety & Comfort

- Why is restoration a cost-effective option for work boots? Extend Boot Life & Save Money

- What are the functional benefits of lace-to-toe boots? Achieve a Superior, Customized Fit

- What makes the best boots suitable for cooler weather? Find the Perfect Cold-Weather Footwear

- What are firefighter boots and what are they designed for? Essential Protection for First Responders

- What features should roofers look for in work boots? Essential Safety and Comfort for the Job

- Why is it important to choose the right work boots? Ensure Safety, Comfort, and Performance

- What are the key features desired in work boots for riding and hiking? Find the Perfect Hybrid Boot