For professionals in demanding environments, selecting the right work boot is a critical decision, and PVC (Polyvinyl Chloride) stands out for a specific set of advantages. PVC work boots are valued primarily for being completely waterproof, highly affordable, lightweight, and resistant to a variety of chemicals, making them a practical choice for many specific applications.

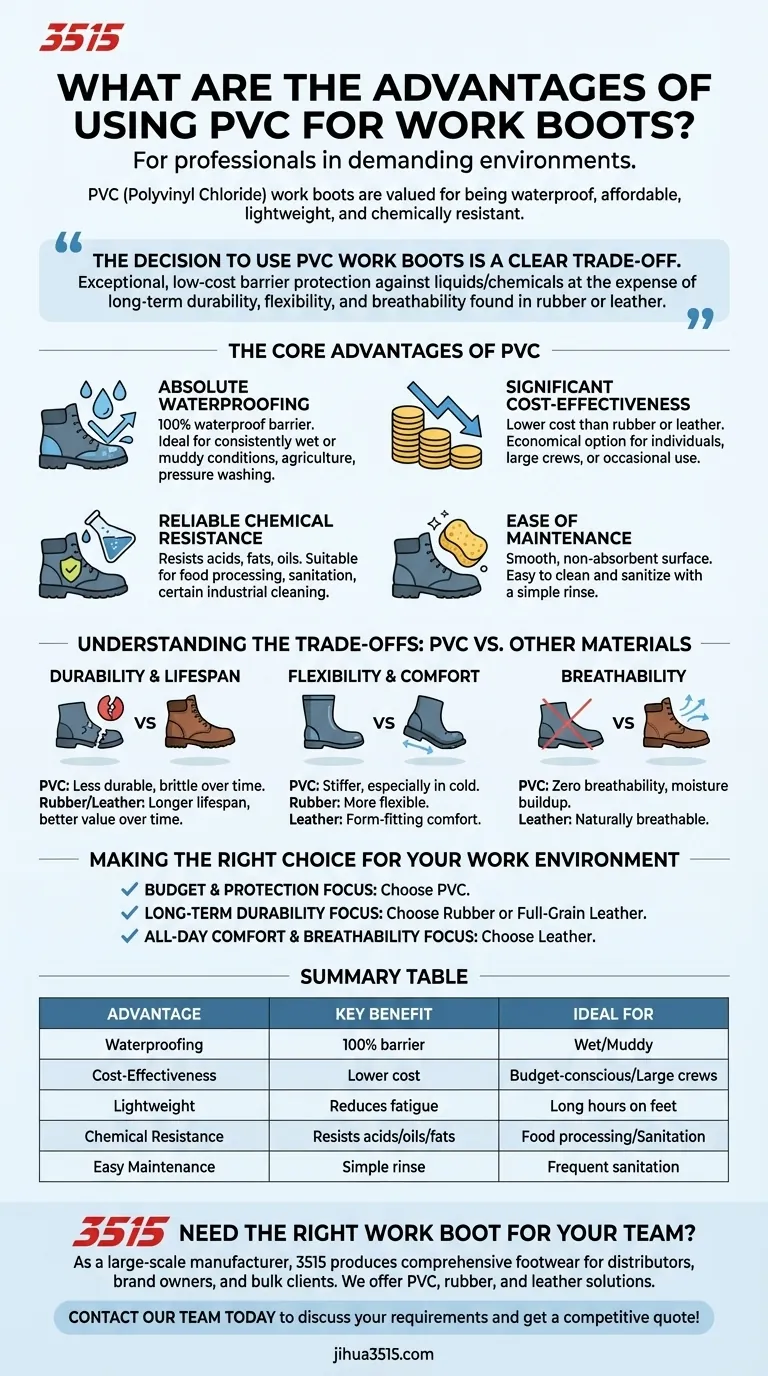

The decision to use PVC work boots is a clear trade-off. They provide exceptional, low-cost barrier protection against liquids and chemicals, but this comes at the expense of the long-term durability, flexibility, and breathability found in materials like rubber or leather.

The Core Advantages of PVC

PVC's material properties translate directly into tangible benefits for workers in certain industries. Understanding these strengths is the first step in determining if they are the right choice for your needs.

Absolute Waterproofing

Because PVC is a non-porous plastic, boots constructed from it offer a 100% waterproof barrier. This makes them an ideal choice for work in consistently wet or muddy conditions, from agriculture to pressure washing.

Significant Cost-Effectiveness

One of the most compelling reasons to choose PVC is its low cost. These boots are generally more affordable than their rubber or leather counterparts, making them an economical option for individuals, large crews, or for occasional use.

Lightweight Construction

PVC boots are notably lightweight. This directly translates to reduced fatigue for the wearer over the course of a long workday, a crucial factor for jobs that require constant standing or walking.

Reliable Chemical Resistance

PVC offers good resistance against a range of chemicals, including many acids, fats, and oils. This makes it a suitable material for use in food processing, sanitation, and certain industrial cleaning environments.

Ease of Maintenance

The smooth, non-absorbent surface of PVC makes these boots incredibly easy to clean and sanitize. A simple rinse is often all that is needed to remove dirt and contaminants.

Understanding the Trade-offs: PVC vs. Other Materials

While the advantages are clear, an objective evaluation requires acknowledging the limitations of PVC, especially when compared to traditional materials like rubber and leather.

Durability and Lifespan

This is the most significant trade-off. PVC is generally less durable than rubber and far less durable than high-quality leather. Over time, it can become brittle, lose its shape, and is more susceptible to cracking or splitting.

Flexibility and Comfort

PVC tends to be a stiffer material than rubber, a difference that can become more pronounced in cold temperatures. While some find them comfortable, they do not offer the flexible comfort of rubber or the form-fitting support that leather develops over time.

Breathability

As a solid plastic, PVC offers zero breathability. In warm environments or during strenuous activity, this can lead to significant moisture and heat buildup inside the boot, causing discomfort. Leather, by contrast, is a naturally breathable material.

Making the Right Choice for Your Work Environment

Your final decision should be based on the specific demands of your job and your primary priorities.

- If your primary focus is budget and protection from water or chemicals: PVC offers an unbeatable combination of low cost and effective barrier protection.

- If your primary focus is long-term durability for daily, rugged wear: Materials like high-quality rubber or full-grain leather will provide a longer lifespan and better value over time.

- If your primary focus is all-day comfort and breathability: Leather is the superior choice, as it molds to your foot and allows moisture to escape.

Ultimately, understanding these material trade-offs is the key to selecting a boot that truly serves your specific needs.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Waterproofing | 100% barrier against liquids | Wet, muddy environments |

| Cost-Effectiveness | Lower cost than rubber/leather | Budget-conscious buyers, large crews |

| Lightweight | Reduces user fatigue | Jobs requiring long hours on feet |

| Chemical Resistance | Resists acids, oils, fats | Food processing, sanitation, industrial cleaning |

| Easy Maintenance | Simple rinse cleans surface | Environments requiring frequent sanitation |

Need the Right Work Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and occupational shoes and boots.

Whether you need the cost-effective barrier protection of PVC or the long-term durability of rubber and leather, we can provide the perfect solution for your workforce's specific needs.

Contact our team today to discuss your requirements and get a competitive quote!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the key characteristics to consider when selecting oilfield work boots? Choose for Maximum Safety & Durability

- What makes PVC work boots resistant to chemicals? The Science Behind Their Industrial Durability

- What are the common materials used for the upper part of work boots? Choose the Right Protection

- What materials are typically used for the outsole of light work boots? Find the Perfect Balance of Durability & Comfort

- What were the consequences of using traditional leather treatments on firefighter boots? Avoid Premature Dry Rot & Cracking

- Why is it important to waterproof leather work boots? Protect Your Investment and Performance

- Why should management prioritize certified high-quality safety boots? Enhance Safety Barriers & Operational Reliability

- How do you apply the wax to the boots in the first step? Master the Foundation for a Perfect Finish