Your work boot is the most critical piece of personal protective equipment you own. When selecting a pair for the oilfield, the key characteristics are its safety certifications (specifically the type of toe cap and slip resistance), the durability of its construction, and a precise, comfortable fit that supports you through a long and demanding shift.

The right oilfield boot is not a simple purchase; it is a critical investment in your personal safety and daily performance. While compliance with ASTM and OSHA standards is the absolute baseline, the specific materials and fit you choose will directly impact your endurance and focus in a hazardous environment.

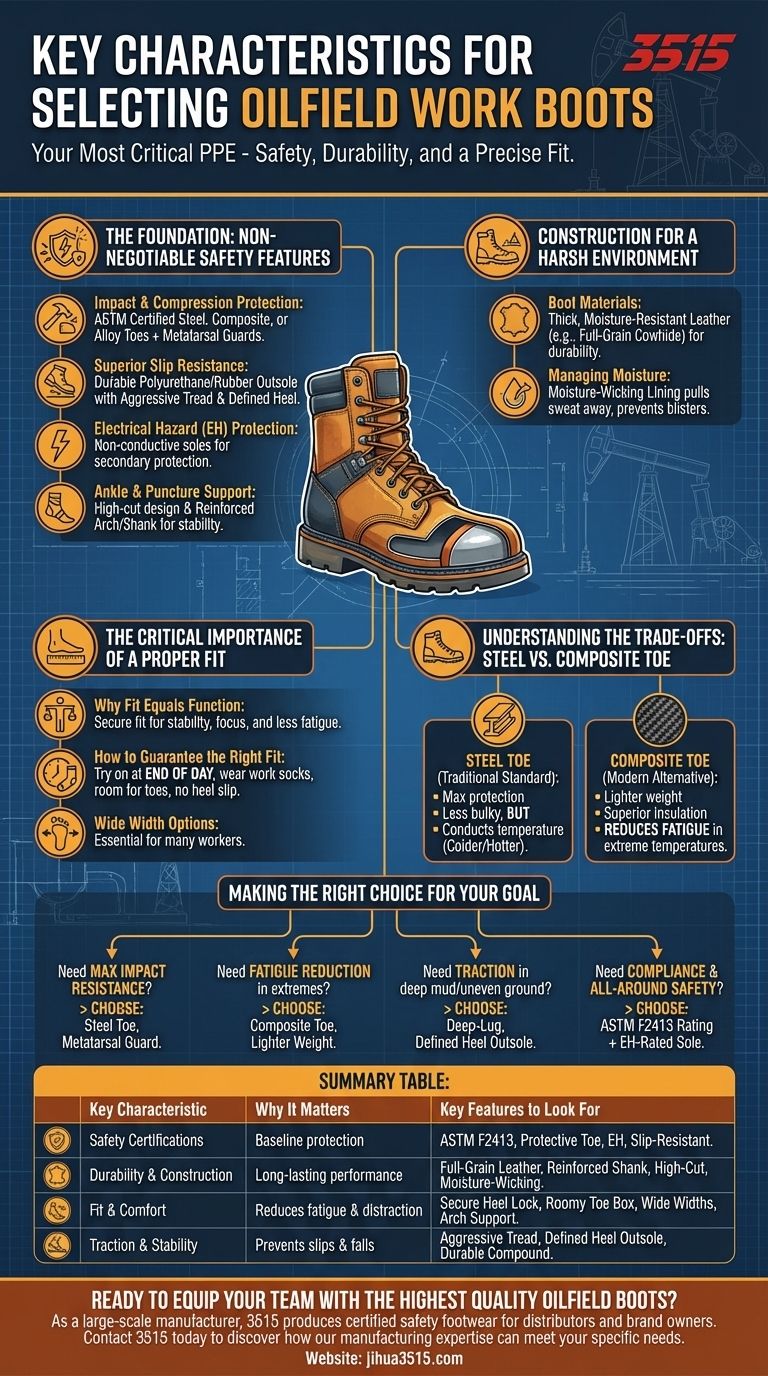

The Foundation: Non-Negotiable Safety Features

An oilfield is an environment of controlled risk. Your boots are your first line of defense against predictable hazards, from falling equipment to slippery surfaces. Every feature is designed to mitigate a specific threat.

Protection from Impact and Compression

The most immediate danger comes from heavy objects and machinery. Your boots must have a certified protective toe cap.

There are three primary types: steel, composite, and alloy. All must meet the same ASTM safety standards for impact and compression, but they offer different secondary benefits. Many boots also include metatarsal guards, which extend protection over the top of your foot.

Superior Slip Resistance

Drilling floors, decks, and work sites are consistently covered in water, mud, and oil. A slip-and-fall accident can be catastrophic.

An effective oilfield boot has a durable polyurethane or rubber outsole with an aggressive tread pattern. Look for boots with a defined heel outsole, as this design provides superior grip and stability in deep mud and on uneven terrain.

Electrical Hazard (EH) Protection

Complex machinery and power sources create a risk of electrical shock.

Boots with an EH rating are constructed with non-conductive soles and heels that can withstand a specific electrical charge under dry conditions, providing a secondary layer of protection.

Ankle and Puncture Support

The work is physically demanding and often involves climbing. Your boots must provide structural support.

A high-cut design is standard, offering crucial ankle support to prevent twists and sprains. Additionally, a reinforced arch or shank not only provides support during long periods of standing but is essential for safely climbing ladders and rig structures.

Construction for a Harsh Environment

Beyond immediate safety features, the boot's materials and build quality determine its lifespan and how well it protects you from the elements.

The Role of Boot Materials

Oilfield boots are built for extreme durability. The uppers are typically made from thick, moisture-resistant leather, such as full-grain cowhide, which stands up to abrasion and harsh chemicals.

Managing Moisture Inside and Out

Keeping your feet dry is essential for both comfort and health. While the leather provides external water resistance, a quality boot also includes a moisture-wicking lining on the inside. This pulls sweat away from your skin, preventing blisters and discomfort.

Understanding the Trade-offs: Steel vs. Composite Toe

The choice between a steel and composite toe cap is one of the most common decisions you'll make. Both are safe, but they have distinct advantages.

The Case for Steel Toes

Steel is the traditional standard for safety toes. It provides maximum protection and can often be housed in a less bulky toe box compared to composite materials. However, steel readily conducts temperature, making boots colder in winter and hotter in summer.

The Case for Composite Toes

Composite toes are made from non-metal materials like carbon fiber, plastic, or Kevlar. Their key advantage is being lighter weight and providing superior insulation against extreme temperatures. This can reduce fatigue over a 12-hour shift and improve comfort in hot or cold climates.

The Critical Importance of a Proper Fit

An ill-fitting boot is more than just uncomfortable—it’s a safety risk. Pain and blisters create distractions, and a sloppy fit reduces your stability.

Why Fit Equals Function

Your boots connect you to your work surface. A secure fit ensures that every step is stable and predictable, allowing you to focus completely on the task at hand without being distracted by foot pain or fatigue.

How to Guarantee the Right Fit

Always try on boots at the end of the day, as your feet naturally swell. Wear the exact type of thick socks you use for work to get an accurate assessment. Ensure there is enough room to wiggle your toes, but your heel should not slip when you walk. Look for brands that offer wide width options if you need them.

Making the Right Choice for Your Goal

Your specific role and environment should guide your final selection.

- If your primary focus is maximum impact resistance: Choose a boot with a steel toe and, if possible, an external metatarsal guard.

- If your primary focus is reducing fatigue in extreme temperatures: Select a boot with a lighter-weight composite toe for better insulation and comfort.

- If your primary focus is traction in deep mud and uneven ground: Prioritize a boot with a deep-lug, defined heel outsole made of high-traction rubber.

- If your primary focus is compliance and all-around safety: Ensure any boot you consider is clearly marked with its ASTM F2413 rating and has an EH-rated sole.

Choosing the correct work boot is a foundational step in preparing yourself for the demands of the oilfield.

Summary Table:

| Key Characteristic | Why It Matters | Key Features to Look For |

|---|---|---|

| Safety Certifications | Baseline protection against workplace hazards. | ASTM F2413 rating, Protective Toe (Steel/Composite), EH Rating, Slip-Resistant Sole. |

| Durability & Construction | Ensures long-lasting performance in extreme conditions. | Full-Grain Leather Upper, Reinforced Shank, High-Cut Ankle Support, Moisture-Wicking Lining. |

| Fit & Comfort | Reduces fatigue and distraction, enhancing safety and focus. | Secure Heel Lock, Roomy Toe Box, Available in Wide Widths, Proper Arch Support. |

| Traction & Stability | Prevents slips and falls on oily, wet, and uneven surfaces. | Aggressive Tread Pattern, Defined Heel Outsole, Durable Rubber/Polyurethane Compound. |

Ready to equip your team with the highest quality oilfield boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable work boots and shoes, built to meet the toughest demands.

We ensure your workforce is protected with boots that combine critical safety features, superior comfort, and long-lasting durability.

Contact 3515 today for a consultation and discover how our manufacturing expertise can meet your specific needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What role have influencers played in the recent popularity of moc toe boots? The Modern Megaphone for a Timeless Style

- How should work boots fit properly? A Guide to All-Day Comfort and Safety

- How do the heels differ between cowboy boots and Western work boots? Choose the Right Heel for Your Job

- Why is proper fit crucial for firefighters' footwear? Avoid Injury and Boost Performance

- What are the main characteristics of RB (Rubber) as a material for work boots? Unmatched Durability & Slip Resistance

- In what work environments are soft-toe boots most suitable? Prioritize Comfort and Agility for Light-Duty Work

- Why is it not advisable to store work boots for long periods? Prevent PU Sole Failure

- What type of socks are recommended for winter work boots? Stay Warm and Dry on the Job