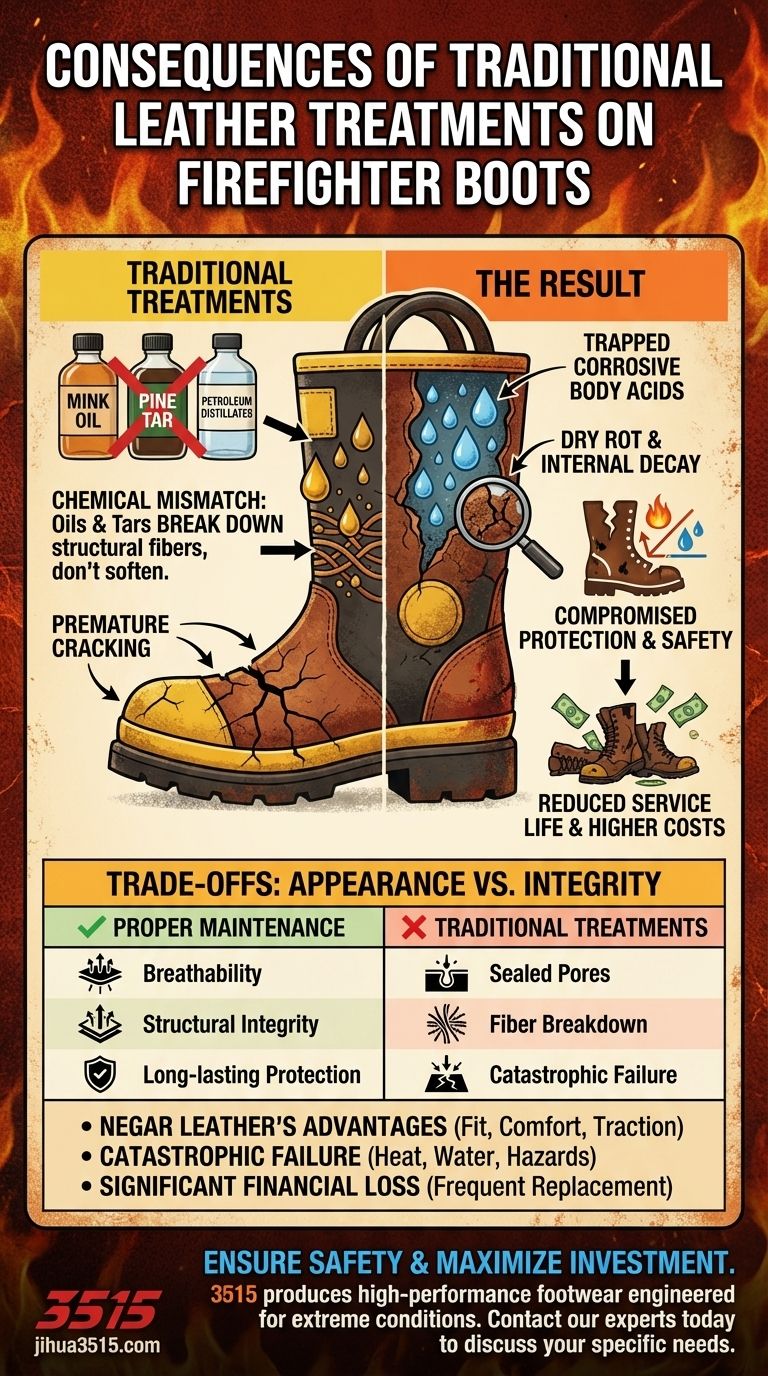

Using traditional leather treatments on firefighter boots leads to their rapid and irreversible destruction. These common household conditioners, designed for casual footwear, contain ingredients that fundamentally compromise the specialized leather used in turnout boots, causing premature cracking and dry rot that drastically shortens their service life.

The core issue is a chemical mismatch: traditional conditioners use oils and tars that break down the structural fibers of performance leather and seal its pores, trapping corrosive body acids and causing the boot to rot from the inside out.

Why Traditional Conditioners Fail on Firefighter Leather

The leather in a firefighter's boot is not the same as the leather in a dress shoe. It is engineered for extreme thermal protection and structural integrity. Applying the wrong treatment fundamentally undermines these properties.

The Myth of "Softening"

Traditional conditioners often contain ingredients like mink oil or pine tar. While these may soften a casual boot, on performance leather they work by chemically breaking down the collagen and protein fibers that give the boot its strength.

This forced softening directly leads to a loss of structural integrity, resulting in the premature and severe cracking seen in improperly maintained boots.

Sealing the Pores: A Critical Mistake

A key function of leather is its ability to breathe. Traditional conditioners create an impermeable seal over the leather's surface, trapping moisture and air.

This prevents the natural dissipation of perspiration that builds up during strenuous activity inside the boot.

The Buildup of Corrosive Acids

When the leather's pores are sealed, the body acids present in sweat have nowhere to go. They become trapped against the leather.

This constant exposure to a concentrated, acidic environment causes the leather to decay from the inside, a condition known as dry rot. This damage is irreparable.

Understanding the Trade-offs: Appearance vs. Integrity

The fundamental error is treating a piece of life-saving equipment like a fashion accessory. The goals are entirely different, and the trade-offs are severe.

Compromised Protection

The cracking and dry rot caused by improper conditioning are not just cosmetic flaws. They represent a catastrophic failure of the boot's protective barrier.

A structurally compromised boot can no longer offer reliable protection against heat, water, or physical hazards, placing the user at significant risk.

Reduced Service Life

Firefighter boots are a significant investment. Using the wrong products guarantees that this investment will be lost prematurely.

The cost of frequent replacement far outweighs the cost of using the correct, manufacturer-recommended cleaning and conditioning products.

Negating Leather's Advantages

Firefighters often prefer leather boots for their superior fit, comfort, and traction.

When the leather's structure is damaged, it loses its ability to mold to the foot and provide support, negating the very reasons it was chosen over rubber alternatives.

How to Apply This to Your Maintenance Protocol

The choice of conditioner is not a minor detail; it is a critical decision that impacts safety and equipment longevity. Your approach must prioritize performance over aesthetics.

- If your primary focus is ensuring safety: You must avoid any treatment containing petroleum distillates, mink oil, or pine tar, as these chemicals will degrade the boot's structural integrity.

- If your primary focus is extending boot lifespan: You must use specialized cleaners and conditioners designed for performance footwear that clean the pores and nourish the leather without sealing it.

Proper maintenance is a non-negotiable component of ensuring your gear performs when it matters most.

Summary Table:

| Consequence | Cause | Effect on Boot |

|---|---|---|

| Premature Cracking | Oils break down leather's structural fibers | Loss of structural integrity |

| Dry Rot | Sealed pores trap corrosive body acids | Internal decay, irreparable damage |

| Compromised Safety | Failure of thermal and water barrier | Increased risk to the firefighter |

| Shortened Service Life | Accelerated wear and degradation | Higher cost of frequent replacement |

Ensure your firefighters' safety and maximize your equipment investment.

As a large-scale manufacturer, 3515 produces high-performance footwear engineered for extreme conditions. We provide durable, properly maintained boots for distributors, brand owners, and bulk clients, ensuring superior protection and longevity.

Contact our experts today to discuss your specific needs and our comprehensive range of safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- What are the durability advantages of pull-on work boots? Fewer Parts, Longer Lasting Performance

- What features should workers exposed to chemicals look for in work boots? Essential Guide for Safety

- How do ergonomic designs enhance comfort in work boots? Boost All-Day Productivity & Reduce Fatigue

- How can moc toe boots be styled with jeans for a rugged look? Master the Fit and Cuff for a Confident Style

- What are the key features to consider when selecting work boots? A Guide to Safety, Durability & Fit

- Why are packer boots considered an investment? Unlock Decades of Durability & Performance

- What are the benefits of wearing the best oilfield work boots? Superior Safety, Durability & Comfort

- What materials contribute to the durability of Western work boots? Uncover the Secrets to Long-Lasting Footwear