The outsoles of light work boots are most commonly constructed from one of four primary materials: Rubber, TPU (Thermoplastic Polyurethane), Polyurethane (PU), or EVA (Ethylene Vinyl Acetate). Each material is selected for a specific balance of durability, traction, and weight to suit various working environments. While rubber is the traditional standard for its toughness, modern synthetics offer lighter and more flexible alternatives.

The choice of an outsole material is a critical trade-off between durability and weight. While dense rubber offers maximum resistance to abrasion and hazards, lighter materials like TPU and EVA significantly reduce foot fatigue during long days of standing or walking.

The Foundation of Your Boot: Key Outsole Materials

The outsole is the part of your boot that makes direct contact with the ground. Its material composition directly dictates its performance in grip, longevity, and comfort.

Rubber: The Industry Standard

Rubber is the most widely used material for work boot outsoles, valued for its exceptional durability and grip.

Its dense composition provides excellent resistance to abrasion, heat, acids, and alkalis, making it a reliable choice for demanding and unpredictable surfaces. Natural rubber is also inherently waterproof and tear-resistant.

TPU (Thermoplastic Polyurethane): The Lightweight Performer

TPU is a modern polymer that offers a compelling alternative to traditional rubber.

It is significantly lighter than rubber yet maintains a high degree of durability. A key advantage of TPU is its superior resistance to splitting or cracking over time, along with good resistance to oils and chemicals.

Polyurethane (PU): A Durable Alternative

Closely related to TPU, polyurethane is another common synthetic outsole material.

PU shares many of the durable and resistant properties of rubber and TPU, often used to create long-lasting soles that can withstand significant wear.

EVA (Ethylene Vinyl Acetate): The Comfort-Focused Option

EVA is a foam-like material prized for its cushioning and flexibility. You'll often find it in athletic footwear.

While not as durable or abrasion-resistant as rubber or TPU, EVA is extremely lightweight. It is often used in light-duty boots to reduce weight and minimize fatigue, providing a softer, more cushioned feel underfoot.

Understanding the Trade-offs

Choosing an outsole is not about finding the single toughest material, but about matching the material's properties to the demands of your job.

Durability vs. Foot Fatigue

The most durable materials, like dense rubber, are also the heaviest. While they provide maximum protection and longevity, the added weight can lead to significant foot fatigue by the end of a long shift.

Lighter materials like TPU and EVA dramatically reduce the energy required to lift your feet with every step, enhancing all-day comfort.

Specialized Resistance

The environment you work in is a critical factor. A standard rubber outsole may be perfect for a construction site but insufficient in an auto garage.

Look for outsoles specifically rated for resistance to oil, chemicals, or high heat if those hazards are part of your daily work. Rubber and TPU often have superior resistance profiles compared to EVA.

The Role of Traction

All outsole materials are designed to provide traction, but the tread pattern and material softness play a huge role.

Softer rubber compounds offer excellent grip on smooth surfaces like concrete but may wear down faster. Harder compounds last longer on abrasive terrain but can be less secure on slick, wet floors.

Making the Right Choice for Your Work

Focus on the primary demand of your workday to select the ideal outsole material.

- If your primary focus is maximum durability and grip on rough terrain: A dense rubber outsole is the most reliable choice for its abrasion and tear resistance.

- If your primary focus is all-day comfort for walking on flat surfaces: Look for boots with lighter TPU or EVA outsoles to minimize weight and reduce fatigue.

- If your primary focus is resistance to oils, chemicals, or heat: Choose a specialized rubber or TPU outsole specifically engineered to withstand those elements.

Ultimately, the right outsole acts as the proper foundation for a safe and comfortable workday.

Summary Table:

| Material | Key Characteristics | Best For |

|---|---|---|

| Rubber | Maximum durability, excellent grip, abrasion/chemical resistant | Demanding, unpredictable surfaces (e.g., construction) |

| TPU | Lightweight, durable, resistant to splitting/oils | All-day comfort with good durability on flat surfaces |

| PU | Durable, long-lasting, wear-resistant | A durable alternative to rubber and TPU |

| EVA | Extremely lightweight, cushioned, flexible | Light-duty work, minimizing foot fatigue |

Need Light Work Boots with the Perfect Outsole?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including light work boots engineered with the optimal outsole material for your target market's needs.

We can help you:

- Source the right boots with outsoles matched to specific job requirements.

- Benefit from high-volume pricing and consistent quality control.

- Customize designs to meet your exact specifications for durability, weight, and traction.

Let's discuss your project. Contact our team today for expert sourcing and manufacturing solutions.

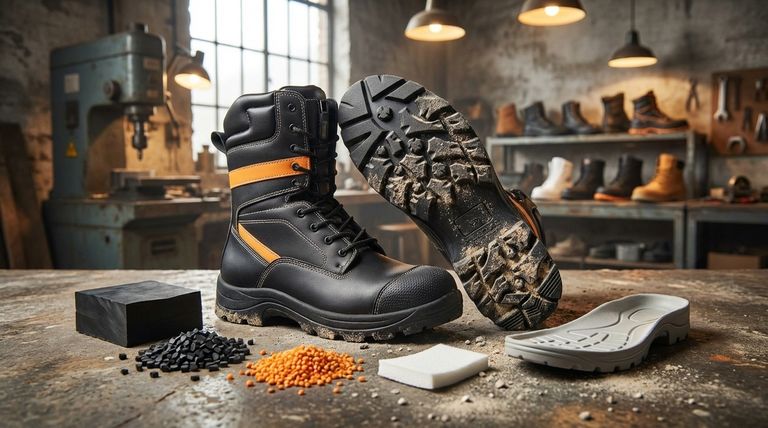

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- What are the key differences between winter boots and normal work boots? Choosing the Right Footwear for Safety and Warmth

- How can scratches on work boots be treated? A Guide to Restoring and Protecting Your Gear

- What should be considered regarding the sole design and material of work boots? Maximize Safety & Comfort

- How does high ankle support improve work boot performance? Prevent Sprains & Boost Stability

- What are the key benefits of Western work boots? Superior Protection, Comfort & Style

- Why do Western-style work boots have higher shafts? Superior Protection & Ankle Support Explained

- What are engineer boots known for? Unmatched Durability & Protection for Demanding Work

- How do pull-on and lace-up boots differ in terms of convenience? The Ultimate Guide to Speed vs. Support