For workers in chemical environments, the most critical features in work boots are chemical-resistant uppers and leak-proof, highly resistant soles, often made of specific rubber or PVC compounds.

I understand the user isn't just looking for a "chemical-resistant" label. They need to choose the right boot material for their specific chemical exposure. No single material resists everything; it's about matching the boot's protection to the hazard. It's a system, not just a product.

I'm going to break this down. First, let's talk about the materials.

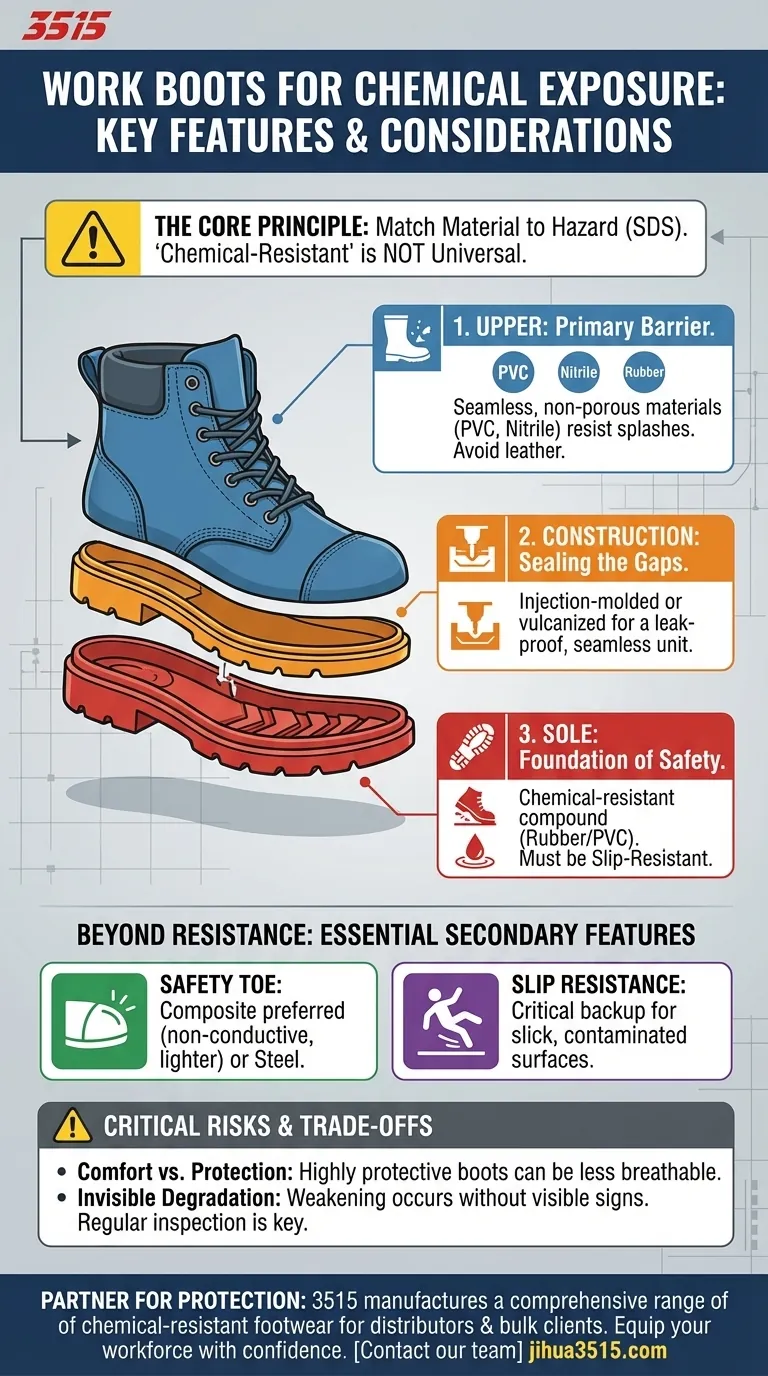

Deconstructing the Chemical-Resistant Boot

The upper is our first line of defense. A true chemical-resistant upper isn't typically leather; it's often synthetic, like PVC, nitrile, or specialized rubber compounds. The construction is just as critical; seamless designs are the best way to prevent leaks at the seams.

Then there's the sole. The references highlight "rubber soles," but it's more nuanced. This isn't just any rubber. We're talking about specific compounds formulated to resist degradation from acids, bases, and solvents. Slip resistance is a must-have, because chemical spills inevitably create slick surfaces.

The construction method matters. A stitched boot risks leaks. Vulcanized or injection-molded construction creates a single, seamless unit offering superior protection against ingress. This is a crucial point that goes beyond the obvious, but it's a key factor for safety.

Beyond Resistance: Essential Secondary Features

While chemical resistance is key, we also need to consider other job-specific needs.

Safety toes, either steel or composite, are a good idea. Steel is the standard, but composite is non-conductive, so it may be preferable in certain electrical environments.

Slip resistance is non-negotiable. Chemical spills are inherently slippery, and a slip-resistant outsole is essential in any chemical environment.

Waterproofing is a starting point, but we're ultimately aiming for chemical-proof boots, a higher standard.

Understanding the Trade-offs and Critical Risks

There are trade-offs to consider, and potential pitfalls to avoid.

"Chemical-resistant" is not a universal term. A boot resistant to acids might fail against solvents. The most critical action is to check the manufacturer's chemical resistance chart and match it to the Safety Data Sheet (SDS) for the chemicals on site.

Highly protective boots can be less breathable and comfortable. This can impact workers during long shifts. Consider models with better insoles or ergonomic design to help with comfort.

Chemical damage doesn't always show. Degradation can weaken the boot without obvious signs like cracking or dissolving. Regular inspection and replacement as per a schedule are essential.

Making the Right Choice for Your Environment

Here's my actionable advice:

- If you work with specific, aggressive chemicals (e.g., strong acids, solvents): Focus on matching the boot material (PVC, nitrile) to the chemical's SDS and prioritize seamless, injection-molded construction.

- If you work in a general environment with incidental chemical splashes (e.g., cleaning agents, mild caustics): A boot with treated leather or a high-quality synthetic upper combined with a sealed, slip-resistant rubber sole may suffice.

- If your role involves both chemical and physical hazards (e.g., heavy objects, wet floors): Ensure your chemical-resistant boot also includes a certified safety toe (steel or composite) and a highly-rated slip-resistant outsole.

Choosing the right boot is an essential part of your personal protective equipment; it requires matching the material directly to the hazard. For workers in chemical environments, the most critical features to look for in work boots are uppers and soles made from materials specifically rated to resist the chemicals you handle. This often means seamless, non-porous materials like PVC or specialized rubber, as these provide a barrier against both degradation and dangerous leaks.

The term "chemical-resistant" is not a universal guarantee. The core principle of safety is to match the boot's specific material composition to the chemical hazards listed in your workplace's Safety Data Sheet (SDS), as no single boot is impervious to all substances.

Deconstructing the Chemical-Resistant Boot

True chemical protection is a system. It involves the upper material, the sole's composition, and the way the two are joined together to create an impenetrable barrier.

The Upper: Your Primary Shield

The upper part of the boot is your first line of defense against splashes and spills. Unlike standard leather, which can absorb chemicals, protective uppers are made from non-porous synthetics.

Look for materials like PVC (Polyvinyl Chloride), nitrile, or other specialized rubber compounds. These materials are inherently resistant to a wide range of acids, bases, and other industrial chemicals.

The Sole: The Foundation of Safety

The outsole makes direct contact with contaminated surfaces. It must not only resist chemical degradation but also prevent slips, a common hazard when chemicals are spilled.

A solid rubber or PVC sole is essential. These materials are less likely to break down or become brittle upon exposure. Critically, the tread pattern should also be designed for slip resistance on wet or slick surfaces.

Construction Method: Sealing the Gaps

The way a boot is constructed is just as important as its materials. Stitched seams, common in many work boots, create tiny holes that can become entry points for chemicals.

For maximum protection, seek out boots with injection-molded or vulcanized construction. This process fuses the upper directly to the sole, creating a single, seamless, and leak-proof unit.

Beyond Resistance: Essential Secondary Features

While chemical resistance is the primary goal, other safety features are necessary for a hazardous industrial environment.

Safety Toes (Steel vs. Composite)

Chemical handling often occurs in areas with physical hazards from falling objects or heavy equipment. A certified safety toe is non-negotiable.

Composite toes are often preferred in chemical environments as they do not conduct electricity and can be lighter than traditional steel.

Slip Resistance

Chemical spills create dangerously slick surfaces. A boot's outsole must be explicitly rated for slip resistance. This feature is a critical backup system that prevents falls and further exposure.

Waterproofing as a Baseline

While all chemical-resistant boots are inherently waterproof, the level of protection is far higher. They are designed to be "chemical-proof," preventing the ingress of substances far more aggressive than water.

Understanding the Trade-offs and Critical Risks

Choosing the right boot requires acknowledging that no single solution is perfect. Understanding the limitations is key to making a safe decision.

"Chemical-Resistant" is Not Universal

This is the single most important concept. A boot that holds up perfectly against strong acids might rapidly degrade when exposed to specific solvents.

You must cross-reference the boot manufacturer's chemical resistance chart with the specific chemicals you handle. This information is found on the product's Safety Data Sheet (SDS).

The Cost of Comfort vs. Protection

Seamless PVC or rubber boots offer the highest level of protection but are typically less breathable than leather boots. This can lead to discomfort over long shifts.

While protection should never be compromised, look for models with ergonomic designs, better insoles, and moisture-wicking liners to mitigate this trade-off.

Degradation Is Not Always Visible

Chemicals can compromise a boot's structural integrity long before you see visible cracks, swelling, or discoloration. The material may become brittle or soft, losing its protective qualities.

Establish and follow a strict inspection and replacement schedule based on your level of exposure and the manufacturer's recommendations.

Making the Right Choice for Your Environment

Your specific work environment and the chemicals you handle dictate the right choice. Use this framework to guide your decision.

- If your primary focus is handling aggressive chemicals (e.g., strong acids, solvents): Prioritize seamless, injection-molded boots made from a material (like PVC or nitrile) specifically rated for those substances.

- If your primary focus is working with incidental chemical splashes (e.g., cleaning agents, mild caustics): A boot with a high-quality synthetic upper and a sealed, slip-resistant rubber sole may provide adequate protection.

- If your primary focus is a mix of chemical and physical hazards (e.g., heavy machinery, wet floors): Ensure your chosen chemical-resistant boot also includes a certified composite safety toe and a highly-rated slip-resistant outsole.

Ultimately, your work boot is a critical piece of personal protective equipment; its effectiveness depends entirely on matching the material directly to the hazard you face.

Summary Table:

| Key Feature | Why It Matters | What to Look For |

|---|---|---|

| Upper Material | Primary barrier against chemical splashes. | PVC, nitrile, or specialized rubber; seamless construction. |

| Sole Material | Resists degradation and prevents slips on contaminated surfaces. | Solid rubber or PVC; slip-resistant tread pattern. |

| Construction Method | Eliminates leak points for complete protection. | Injection-molded or vulcanized (seamless) design. |

| Safety Toe | Protects against physical hazards in industrial settings. | Composite or steel toe, certified to safety standards (e.g., ASTM). |

Protect your workforce with the right gear. As a leading manufacturer, 3515 produces a comprehensive range of chemical-resistant footwear designed for distributors, brand owners, and bulk clients. Our expertise in materials like PVC and specialized rubber ensures your teams have durable, safe, and compliant boots tailored to specific chemical hazards.

Let us help you equip your workforce with confidence. Contact our team today to discuss your requirements and explore our production capabilities for all types of safety shoes and boots.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why is Production Capacity (Mcap) a core parameter in safety shoe contracts? Optimize Supply and Mitigate Risk

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety