Beyond the obvious function of a steel toe, a modern safety boot is a specialized tool designed to counter a wide array of workplace hazards. They provide critical protection against impact from heavy equipment, punctures from sharp objects like nails, electrical shocks from live wires, and slips on hazardous surfaces, in addition to guarding against chemical and thermal dangers.

The term "safety toe" refers to only one component of a protected footwear system. True on-site safety comes from understanding the specific combination of hazards in your environment and selecting a boot with the corresponding certified features.

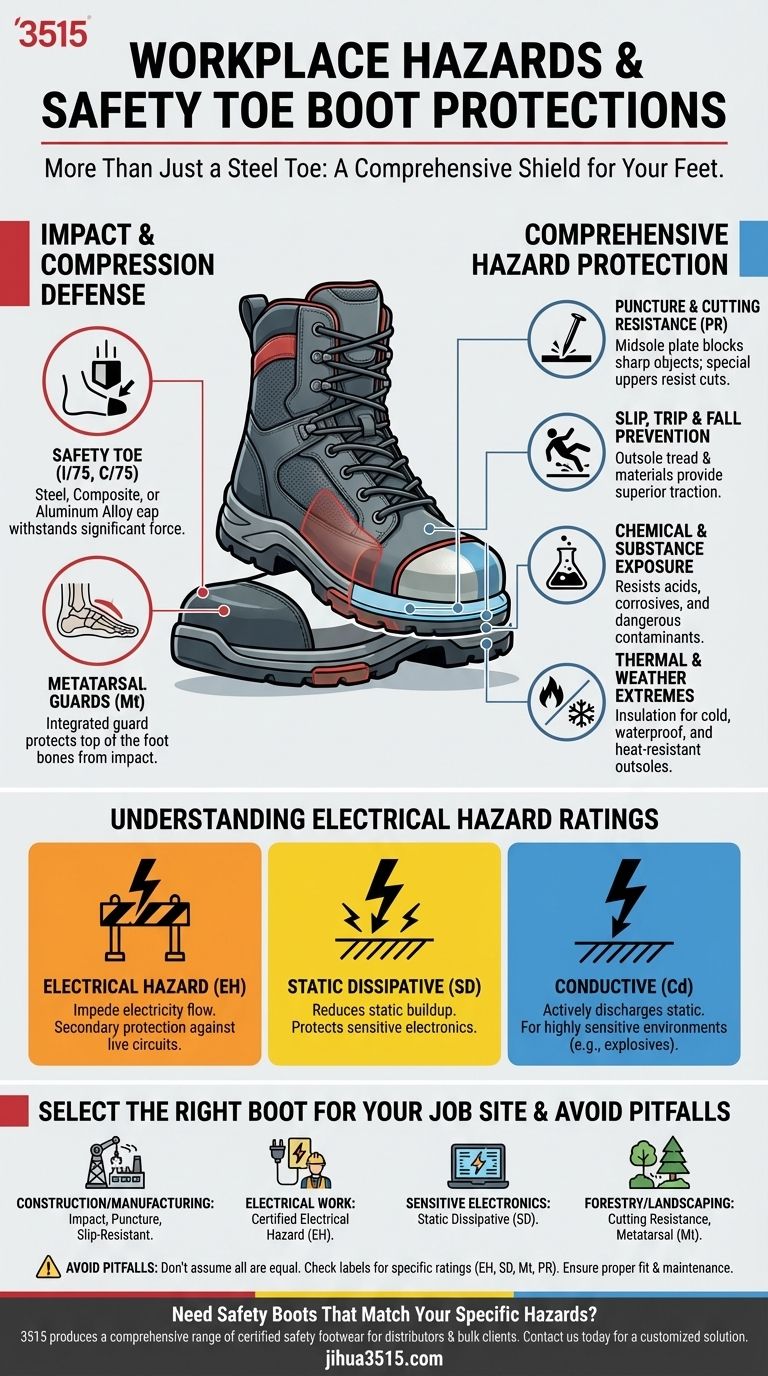

The Core Protections: Impact and Compression

The foundational purpose of any safety boot is to protect the foot from being crushed or broken. This is achieved through several key features.

The Role of the Safety Toe

This is the most well-known feature. A reinforced toe box, typically made of steel, composite materials, or aluminum alloy, is designed to withstand significant force from falling objects or compression from heavy machinery.

Metatarsal Guards (Mt) for Added Coverage

Some jobs pose a risk to the top of the foot, not just the toes. Boots with a Metatarsal (Mt) rating include an integrated guard that protects the delicate metatarsal bones from impact.

Beyond the Toe Cap: Comprehensive Hazard Defense

While the safety toe is crucial, a truly effective work boot addresses the full spectrum of potential risks present on a job site.

Puncture and Cutting Resistance

The sole of the boot is a critical line of defense. Many safety boots include a puncture-resistant plate in the midsole to protect against sharp objects like nails, screws, and staples from piercing through the bottom of the foot. Specialized boots also offer uppers designed to resist cuts from tools like chainsaws.

Slip, Trip, and Fall Prevention

Slips are one of the most common workplace accidents. The outsole of a safety boot is engineered with specific tread patterns and materials to provide superior traction on slippery surfaces, including water, oil, or chemical spills.

Chemical and Substance Exposure

In environments with hazardous materials, the boot's upper material is vital. Safety boots can be constructed from materials that resist degradation from acids, corrosive substances, and other dangerous contaminants, preventing chemical burns and exposure.

Thermal and Weather Extremes

Protection from the environment is also a key function. This includes insulated boots for extreme cold, waterproof construction for wet conditions, and outsoles designed to withstand contact with hot surfaces or even fire.

Understanding Electrical Hazard Ratings

For anyone working near electricity, understanding the specific electrical rating of their boot is non-negotiable. These ratings are not interchangeable.

Electrical Hazard (EH)

An Electrical Hazard (EH) rated boot is designed to impede the flow of electricity. It provides a secondary source of protection for workers who may come into accidental contact with live electrical circuits, helping to prevent electrocution.

Static Dissipative (SD)

Static Dissipative (SD) footwear is engineered to reduce the buildup of static electricity in the wearer's body. This is crucial in environments where a static discharge could damage sensitive electronic equipment or ignite flammable materials.

Conductive (Cd)

Less common, Conductive (Cd) footwear is designed to do the opposite of EH boots. It actively discharges static electricity from the body into the ground to prevent any static buildup whatsoever. This is used in highly sensitive environments, such as those involving explosive materials.

Common Pitfalls to Avoid

Choosing the wrong boot can create a false sense of security, which is often more dangerous than having no protection at all.

Assuming All Safety Boots Are Equal

A boot with a steel toe offers impact protection but provides no guaranteed defense against electrical shock, punctures, or chemical spills unless it is specifically rated for those hazards.

Ignoring the Specific Hazard Codes

Always check the boot's label or tag for its official ratings (EH, SD, Mt, PR for puncture resistance). These codes are the only way to be certain of the specific protections the boot provides.

Neglecting Proper Fit and Maintenance

Even the highest-rated boot is ineffective if it fits poorly or its protective features are compromised by excessive wear and tear. A cracked sole or worn-down upper can negate the boot's safety ratings.

How to Select the Right Boot for Your Job Site

Your choice must be dictated by a clear analysis of your work environment.

- If your primary focus is construction or manufacturing: Prioritize impact protection (safety toe), puncture resistance, and a high-traction, slip-resistant outsole.

- If your primary focus is electrical work: You must select a boot with a certified Electrical Hazard (EH) rating to protect against shock.

- If your primary focus is working with sensitive electronics: A Static Dissipative (SD) boot is necessary to protect the equipment from static discharge.

- If your primary focus is forestry or heavy landscaping: Look for specific cutting resistance features and metatarsal (Mt) guards in addition to impact and slip protection.

Choosing the right safety boot is an active and essential part of your personal protective equipment strategy.

Summary Table:

| Hazard Type | Key Boot Features | Common Certifications |

|---|---|---|

| Impact & Compression | Reinforced toe box (steel/composite), Metatarsal guard | ASTM F2413-18 (I/75, C/75), Mt |

| Puncture & Cutting | Puncture-resistant midsole, cut-resistant uppers | ASTM F2413-18 (PR), Chainsaw Protection |

| Slips & Falls | High-traction outsoles, slip-resistant materials | ASTM F2913 (SATRA TM144) |

| Electrical Hazards | Insulating materials, static control | EH (Electrical Hazard), SD (Static Dissipative), Cd (Conductive) |

| Chemical & Thermal | Chemical-resistant uppers, insulated/waterproof construction | Varies by material (e.g., rubber, PVC) |

Need Safety Boots That Match Your Specific Hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, including impact-resistant, puncture-proof, electrical hazard-rated, and slip-resistant models—all tailored to meet your job site's unique demands.

Contact us today for a customized solution that ensures compliance, durability, and total protection for your workforce.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What safety boots are recommended for the oil and gas industry? Essential Features for Hazardous Sites

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- Why is the use of professional safety shoes critical for injection molding? Prevent Injuries with High-Impact Footwear

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What do the symbols on safety footwear indicate? A Guide to Decoding Boot Safety Ratings