Beyond protecting your feet, a complete safety setup often requires additional equipment based on your specific work environment. The most common additions to work boots include eye protection, hearing protection, specialized work gloves, and respiratory masks.

Your work boots are the foundation, but true safety comes from viewing them as one part of an integrated Personal Protective Equipment (PPE) system designed to shield you from all potential workplace hazards.

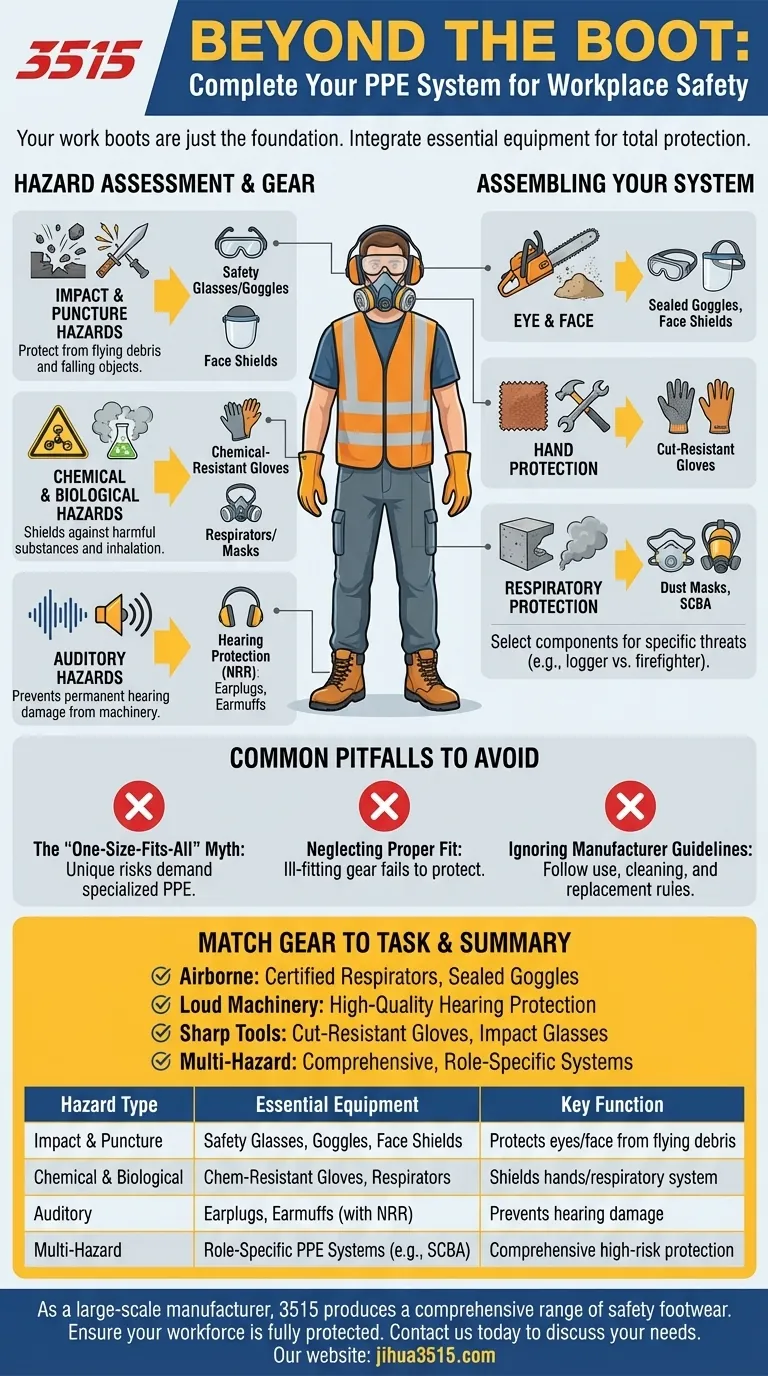

Beyond the Boot: Assessing Your Workplace Hazards

The equipment you need is dictated entirely by the risks you face. A proper assessment of your work environment is the critical first step before selecting any gear.

Impact and Puncture Hazards

Many job sites present a risk of flying debris from cutting, grinding, or demolition. You must also consider the danger of falling objects or sharp materials underfoot.

This is where safety glasses or goggles become essential to protect your vision. For more extreme risks, a full face shield may be required.

Chemical and Biological Hazards

If you work with chemicals, solvents, or biological materials, skin contact and inhalation are major concerns. Your boots may be chemically resistant, but this is only part of the solution.

In these cases, chemical-resistant gloves and respirators or safety masks are non-negotiable to protect your hands and respiratory system.

Auditory Hazards

Prolonged exposure to loud noise from machinery, power tools, or industrial processes can cause permanent hearing damage.

Hearing protection, such as earplugs or earmuffs with an appropriate Noise Reduction Rating (NRR), is crucial in these environments.

Assembling Your Complete PPE System

Once you understand the hazards, you can select the right components to build your safety system. Each piece of equipment is designed for a specific threat.

Eye and Face Protection

An arborist or logger using a chainsaw needs protection from flying wood chips. Standard safety glasses are a minimum, but sealed goggles offer superior defense against fine dust and particles.

Hand Protection

The same logger needs durable, often cut-resistant gloves for handling rough materials and operating dangerous tools. In contrast, someone in emergency medical services (EMS) will require disposable medical-grade gloves.

Respiratory Protection

A construction worker cutting concrete may only need a simple dust mask. However, a firefighter entering a burning structure requires a Self-Contained Breathing Apparatus (SCBA) for a breathable air supply, a far more advanced form of protection.

Common Pitfalls to Avoid

Simply owning safety equipment is not enough. To be effective, it must be chosen correctly and used properly.

The "One-Size-Fits-All" Myth

The gear required for a law enforcement officer is vastly different from that needed by a logger. Each role has a unique risk profile that demands a specialized PPE solution.

Neglecting Proper Fit

Ill-fitting equipment can be as dangerous as no equipment at all. Safety glasses that slip, gloves that are too loose, or a poorly sealed respirator will fail to provide adequate protection.

Ignoring Manufacturer Guidelines

Every piece of safety equipment has performance limits and maintenance requirements. Always follow the manufacturer's recommendations for use, cleaning, and replacement to ensure it functions as intended.

Matching Your Gear to Your Task

Use your specific work hazards to guide your choices.

- If your primary hazard is airborne particles or fumes: Your first priority after boots should be certified respiratory protection and sealed eye goggles.

- If your primary hazard is loud machinery: Invest in high-quality hearing protection that is comfortable for all-day wear.

- If your primary hazard involves sharp tools or materials: Cut-resistant gloves and impact-rated safety glasses are your most critical additions.

- If you work in a multi-hazard environment like logging or emergency services: A comprehensive, role-specific system is essential, and you must be trained on how each component works together.

Ultimately, workplace safety is a system, and your boots are just the starting point.

Summary Table:

| Hazard Type | Essential Additional Equipment | Key Function |

|---|---|---|

| Impact & Puncture | Safety Glasses, Goggles, Face Shields | Protects eyes and face from flying debris |

| Chemical & Biological | Chemical-Resistant Gloves, Respirators | Shields hands and respiratory system from harmful substances |

| Auditory | Earplugs, Earmuffs (with NRR) | Prevents hearing damage from loud machinery |

| Multi-Hazard (e.g., Logging, EMS) | Role-Specific PPE Systems (e.g., Cut-Resistant Gloves, SCBA) | Comprehensive protection for high-risk environments |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots.

Ensure your workforce is fully protected with a complete PPE system tailored to your specific hazards. Contact us today to discuss your safety footwear needs and benefit from our expertise in durable, reliable manufacturing for high-risk environments.

Visual Guide

Related Products

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the key characteristics of cowboy boots for farm work? Durable, Stable & Protective Footwear

- What are the essential features of fire boots? A Guide to Maximum Safety & Performance

- How do insulated boots provide long-term health benefits? Prevent Nerve Damage & Frostbite

- What is an alternative to waterproof wax for quick application? Aerosol Sprays for Instant Protection

- How do pull-on work boots compare to other types? Choose the Right Boot for Your Job

- How can you identify a waterproof boot? Look for the 'WR' Code for Guaranteed Protection.

- Why is it important to maintain waterproof leather boots? Extend Lifespan & Performance

- What makes chemical-resistant boots suitable for certain environments? Essential Protection for Hazardous Work