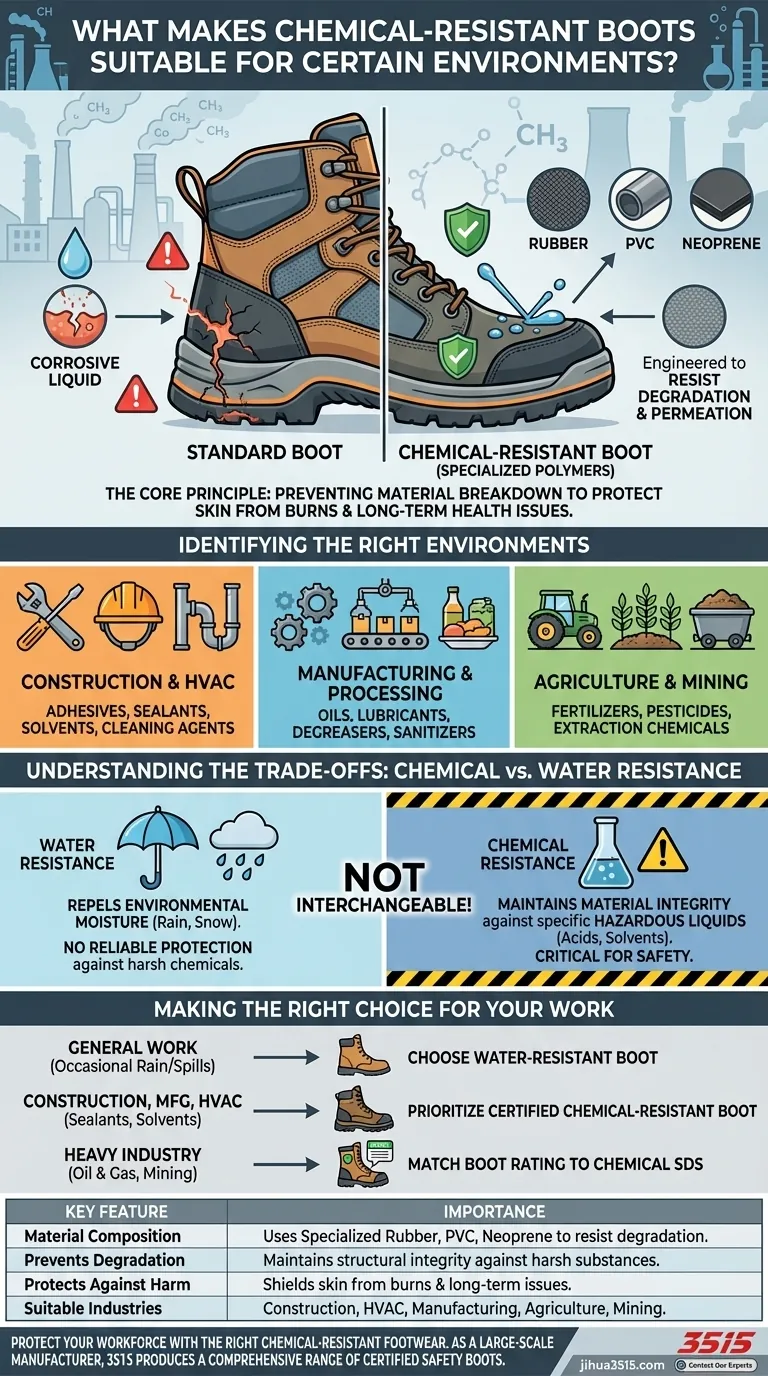

The fundamental quality that makes chemical-resistant boots suitable for certain environments is their material composition. They are constructed from specific polymers, like rubber or PVC, that are engineered to resist degradation, corrosion, and permeation when exposed to hazardous substances such as acids, solvents, sealants, and powerful cleaning agents.

The suitability of a safety boot isn't just about a single feature; it's about matching the boot's specific material and construction to the unique chemical hazards present in a given work environment. Choosing correctly is a critical safety decision.

The Core Principle of Chemical Resistance

To select the right footwear, you must first understand how it provides protection. The mechanism goes beyond simply being a barrier; it's about material science.

Material Composition is Key

The primary materials used in these boots—such as specialized rubber, PVC, or neoprene—are chosen for their non-reactive properties. These materials do not break down or lose their structural integrity when they come into contact with specific chemicals.

Preventing Degradation, Not Just Repelling

A standard boot might repel a splash of water, but a harsh chemical can cause its material to weaken, crack, or even dissolve over time. Chemical-resistant boots are designed to prevent this material degradation, ensuring the barrier between the worker and the hazard remains intact.

Protection Against Direct Harm

The ultimate goal is to prevent dangerous substances from reaching the skin. This protects workers from immediate harm like chemical burns and long-term health issues that can arise from absorption through the skin.

Identifying the Right Environments

While many jobs require safety footwear, only those with specific chemical hazards necessitate this level of protection. The key is to assess the substances a worker will encounter.

Construction and HVAC

Workers in these fields frequently handle adhesives, sealants, solvents, and industrial cleaning agents. Chemical-resistant boots are crucial for protecting against spills and splashes during application or cleanup.

Manufacturing and Processing

In environments like manufacturing, food processing, or foundries, workers are often exposed to oils, lubricants, degreasers, and sanitizing chemicals. The right boot ensures both safety and durability in these conditions.

Agriculture and Mining

These industries often use fertilizers, pesticides, and various extraction chemicals. Boots designed for this work must resist these specific substances to keep workers safe during daily operations.

Understanding the Trade-offs: Chemical vs. Water Resistance

A common point of confusion is the difference between chemical resistance and water resistance. These features are not interchangeable, and mistaking one for the other can be dangerous.

The Purpose of Water Resistance

Water-resistant or waterproof boots are designed to protect against environmental moisture like rain, puddles, or snow. Their materials are treated to repel water but offer no reliable protection against corrosive or reactive chemicals. They are suitable for general outdoor work where no chemical hazards are present.

The Purpose of Chemical Resistance

Chemical-resistant footwear is built for a much more aggressive type of exposure. The focus is on material integrity against specific hazardous liquids, which may or may not be water-based.

Why They Are Not Interchangeable

Using a water-resistant boot in an environment with chemical hazards provides a false sense of security. The chemicals can quickly compromise the boot material, leading to exposure and injury. Always match the boot's specific rating to the hazard.

Making the Right Choice for Your Work Environment

Selecting the proper boot requires a clear understanding of your daily tasks and potential exposures.

- If your primary focus is general work with occasional rain or spills: A standard water-resistant or waterproof boot is a suitable and effective choice.

- If your primary focus is construction, HVAC, or manufacturing: Prioritize certified chemical-resistant boots, as exposure to sealants, solvents, or cleaning agents is highly probable.

- If your primary focus is heavy industry with known hazards (oil & gas, mining): You must match the boot's specific resistance rating to the safety data sheets for the chemicals present in your workplace.

Ultimately, choosing the right safety boot is an essential part of your personal protective equipment, directly impacting your safety and well-being on the job.

Summary Table:

| Key Feature | Importance |

|---|---|

| Material Composition | Uses specialized rubber, PVC, or neoprene to resist degradation from chemicals. |

| Prevents Degradation | Maintains structural integrity against harsh substances, unlike standard boots. |

| Protects Against Harm | Shields skin from chemical burns and long-term health issues. |

| Suitable Industries | Construction, HVAC, Manufacturing, Agriculture, Mining. |

Protect your workforce with the right chemical-resistant footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of chemical-resistant footwear, designed to meet the specific hazards of your industry—from construction solvents to industrial cleaners.

We ensure durability, compliance, and worker safety. Let's discuss your needs and find the perfect protective solution for your team.

Contact our experts today for a consultation

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What protective functions do industrial safety shoes provide in petroleum environments? Secure Your Workers' Health

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- Why is the use of professional safety shoes critical for injection molding? Prevent Injuries with High-Impact Footwear