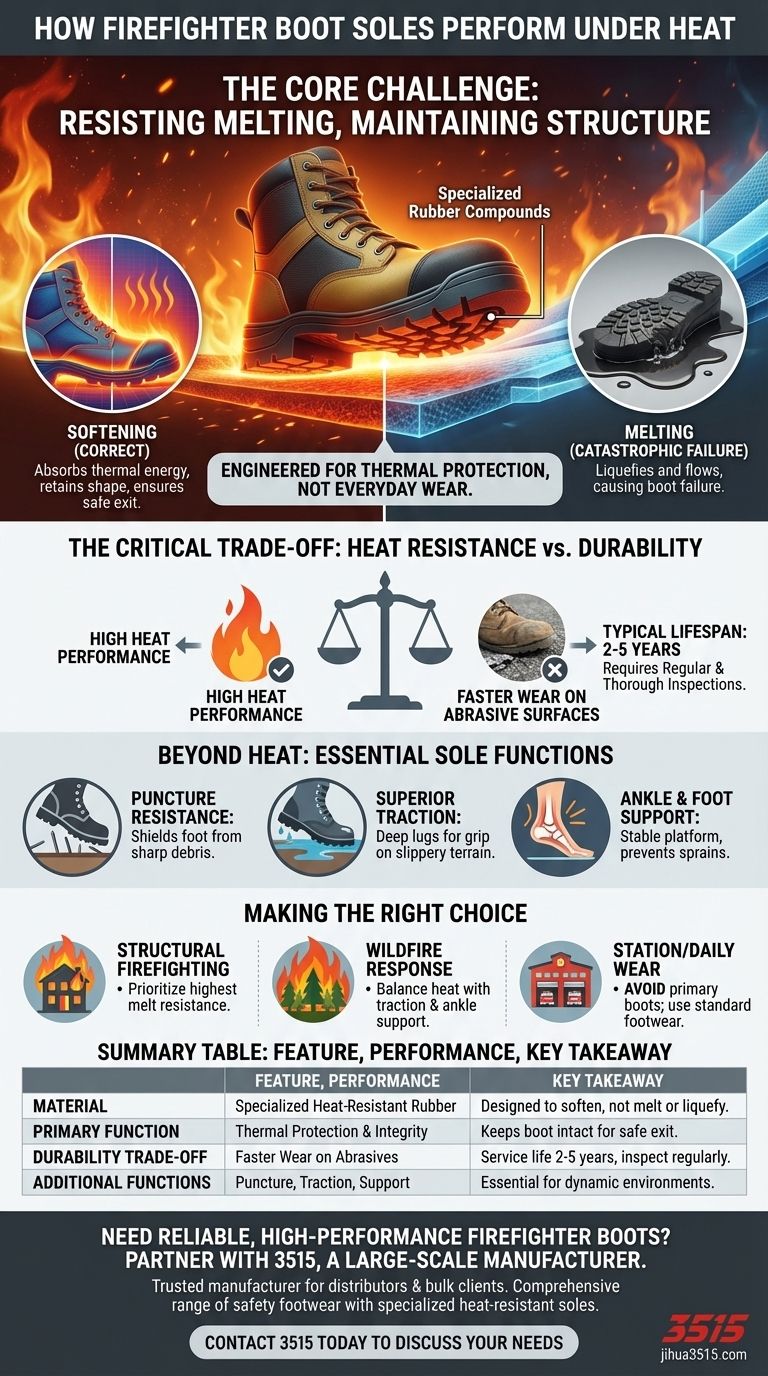

At its core, a firefighter boot sole is engineered to resist melting under extreme heat, maintaining its structure to protect the wearer. Specialized, melt-resistant lug soles, such as the Vibram Red X, are designed to soften when exposed to high temperatures but will not liquefy or flow, preventing catastrophic failure in a hazardous environment.

The primary function of a firefighter's boot sole is thermal protection. This is achieved through specialized rubber compounds that prioritize melt resistance over long-term wear durability, a critical trade-off for safety.

The Engineering Behind Heat Resistance

The performance of a firefighter's boot sole in high heat is not an accident; it's the result of specific material science and design choices intended to function under the most demanding conditions.

Specialized Rubber Compounds

The soles are not made from standard rubber. They utilize proprietary, heat-resistant compounds specifically formulated to withstand the thermal loads encountered during firefighting operations.

Softening vs. Melting

A key distinction is that these soles are designed to soften, not melt. This softening allows the material to absorb thermal energy without losing its fundamental shape, ensuring the boot remains a protective barrier.

Maintaining Structural Integrity

The ultimate goal is to keep the boot intact long enough for a firefighter to work and, more importantly, exit a superheated environment safely. The sole must not delaminate or disintegrate when it matters most.

Understanding the Trade-offs

Engineering a material for extreme heat performance inevitably involves compromises in other areas. This balance is critical to understanding the boot's overall function and lifespan.

The Durability Compromise

The softer material required for high heat resistance leads to faster wear compared to a standard work boot. Walking on abrasive surfaces like asphalt or concrete will degrade a firefighter's sole much more quickly.

Lifespan and Inspection

Due to this accelerated wear, high-quality firefighter boots typically have a service life of 2 to 5 years. This makes regular and thorough inspections for wear, cuts, or heat damage absolutely essential for ensuring continued safety.

Beyond Heat: Other Critical Sole Functions

While heat resistance is paramount, a firefighter's boot sole must perform several other functions to be truly effective and safe in a dynamic, unpredictable environment.

Puncture Resistance

The sole must be thick and robust enough to protect the foot from nails, glass, and other sharp debris commonly found in fire and rescue scenes.

Superior Traction

A deep, aggressive lug pattern is essential. The sole needs to provide a solid grip on wet, oily, or uneven surfaces to prevent slips and falls.

Ankle and Foot Support

The sole is the foundation of the boot's support system. It must be stable enough to help prevent sprains and provide a secure platform, especially for wildland firefighters navigating rough terrain.

Making the Right Choice for Your Needs

Selecting the right boot means aligning its specific features with the primary demands of your role.

- If your primary focus is structural firefighting: Prioritize boots with the highest-rated melt-resistant soles to ensure maximum protection against extreme interior temperatures.

- If your primary focus is wildfire response: Balance heat resistance with features like superior traction for loose surfaces and robust ankle support for uneven terrain.

- If you need a boot for station or daily wear: Avoid using your primary firefighting boots for routine tasks, as their specialized, softer soles will wear out prematurely.

Ultimately, a firefighter's boot sole is a purpose-built piece of safety equipment where life-saving heat performance is correctly prioritized over everyday durability.

Summary Table:

| Feature | Performance Under Heat | Key Takeaway |

|---|---|---|

| Material | Specialized heat-resistant rubber compounds | Designed to soften, not melt or liquefy |

| Primary Function | Thermal protection and structural integrity | Keeps the boot intact for safe exit from superheated environments |

| Durability Trade-off | Faster wear on abrasive surfaces | Service life is typically 2-5 years; requires regular inspection |

| Additional Functions | Puncture resistance, superior traction, ankle support | Essential for safety on wet, oily, or debris-filled terrain |

Need Reliable, High-Performance Firefighter Boots? Partner with 3515, a Large-Scale Manufacturer.

As a trusted manufacturer for distributors, brand owners, and bulk clients, 3515 produces a comprehensive range of safety footwear. Our production capabilities encompass all types of professional boots, including those engineered with the specialized, heat-resistant soles detailed in this article. We ensure your teams are equipped with footwear that prioritizes safety without compromising on critical features like traction and support.

Contact 3515 today to discuss your specific needs and discover how our manufacturing expertise can provide the durable, life-saving footwear your customers depend on.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why is the ISO 5349 standard used instead of ISO 2631-1 for high-frequency foot vibration? Protect Your Feet Today

- Why are safety shoes critical for compliance? Essential for Risk Mitigation & Legal Protection

- What role does simulation and prototype design software play in safety shoe manufacturing? Optimize Your Production

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- Are composite toe boots puncture resistant? No, and here's why toe protection and sole safety are different.

- How does the shock absorption of industrial-grade footwear protect the knee? Essential Safety Guide

- How should professional functional footwear, such as safety shoes and tactical boots, be optimized based on load-bearing gait research? For Enhanced Stability & Performance

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety