At its core, safety footwear is critical for compliance because it is a legally mandated form of Personal Protective Equipment (PPE) designed to meet specific, enforceable industry standards. Providing certified safety shoes is a non-negotiable requirement in high-risk environments, and failure to do so directly exposes an organization to legal sanctions, fines, and liability in the event of an incident.

While meeting regulatory requirements is the immediate trigger, the true function of a safety footwear program is to fundamentally mitigate operational risk. It serves as a critical control that protects against costly injuries, lost productivity, and the legal consequences that follow workplace accidents.

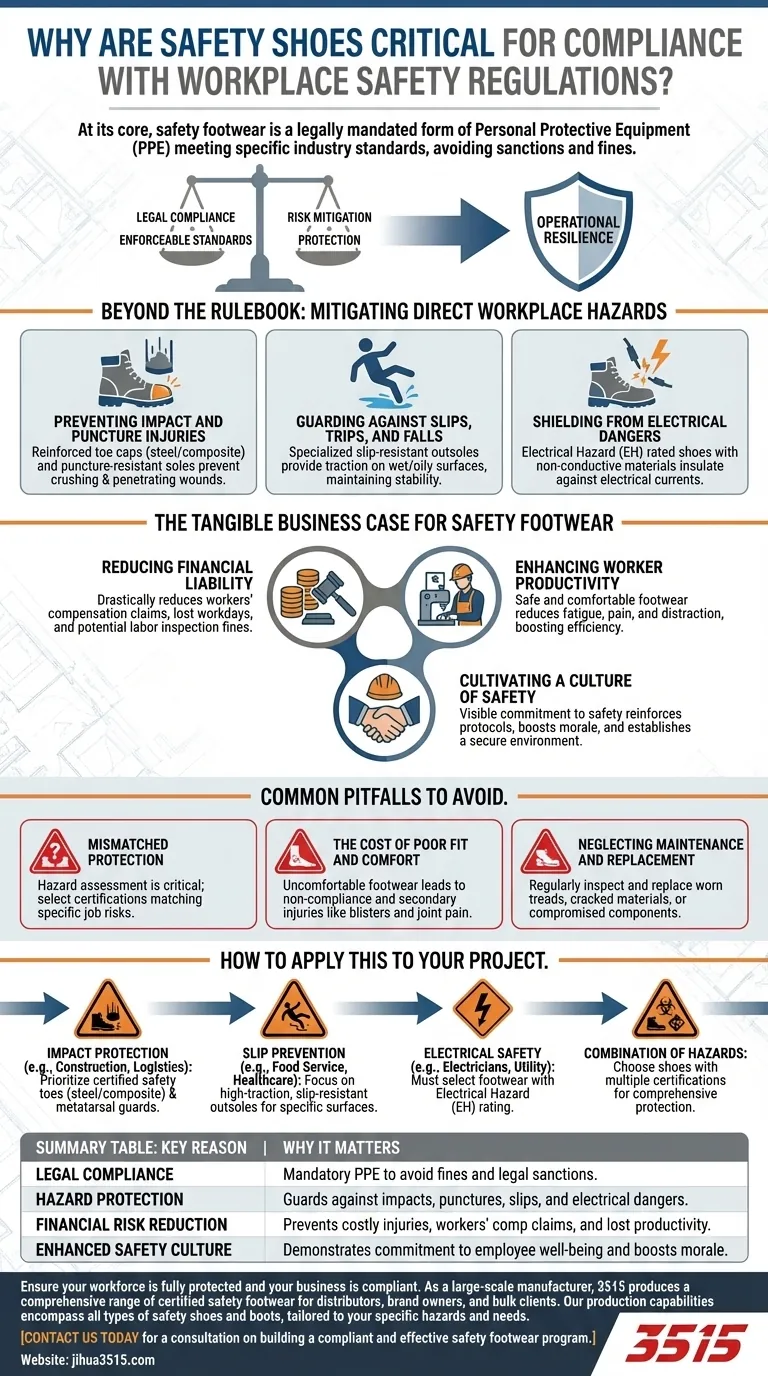

Beyond the Rulebook: Mitigating Direct Workplace Hazards

Regulations exist to address tangible dangers. Safety shoes are the frontline defense against common and severe foot-related injuries that can halt operations and permanently affect an employee's well-being.

Preventing Impact and Puncture Injuries

In environments like construction sites or manufacturing plants, the risk of heavy objects falling or sharp materials underfoot is constant. Safety shoes with reinforced toe caps (steel or composite) and puncture-resistant soles directly prevent crushing injuries and penetrating wounds.

Guarding Against Slips, Trips, and Falls

Slips, trips, and falls are among the most frequent causes of workplace injuries, especially on wet or oily surfaces common in kitchens, healthcare, and industrial settings. Specialized slip-resistant outsoles provide the necessary traction to maintain stability and prevent these incidents.

Shielding from Electrical Dangers

For electricians or maintenance personnel working near live circuits, electrical shock is a life-threatening risk. Electrical Hazard (EH) rated shoes are built with non-conductive materials that insulate the wearer, acting as a crucial barrier against electrical currents.

The Tangible Business Case for Safety Footwear

Implementing a compliant safety shoe program is not just an expense; it is an investment in operational stability and financial health. The costs associated with a single foot injury often far exceed the cost of prevention.

Reducing Financial Liability

According to the National Safety Council, foot trauma accounts for tens of thousands of work-related injuries annually. Each incident can trigger significant costs, including workers' compensation claims, lost workdays, and potential fines from labor inspections. Proper footwear drastically reduces this financial exposure.

Enhancing Worker Productivity

A worker who feels safe and comfortable is more focused and efficient. The right safety shoes prevent the pain and distraction caused by inadequate footwear, reducing fatigue and allowing employees to concentrate fully on their tasks.

Cultivating a Culture of Safety

Providing high-quality PPE is one of the most visible ways an employer can demonstrate a genuine commitment to worker safety. This act reinforces safety protocols, boosts morale, and helps establish a secure environment where every team member feels valued and protected.

Common Pitfalls to Avoid

Simply providing "safety shoes" is not enough to ensure compliance or effective protection. A successful program requires careful consideration and management.

Mismatched Protection for the Hazard

Not all safety shoes are created equal. A steel-toe boot offers no protection from electrical currents, and a slip-resistant shoe may not prevent a puncture wound. It is critical to perform a hazard assessment and select footwear with the specific certifications that match the risks of the job.

The Cost of Poor Fit and Comfort

If footwear is uncomfortable, employees are less likely to wear it correctly or may even avoid wearing it altogether, rendering the entire program useless. An ill-fitting shoe can also create secondary problems like blisters, joint pain, and fatigue, negatively impacting productivity.

Neglecting Maintenance and Replacement

Safety shoes are not permanent. Worn-out treads, cracked materials, or compromised safety toes can fail at a critical moment. Employers are responsible for ensuring footwear is properly maintained and replaced when it no longer meets safety standards.

How to Apply This to Your Project

Your choice of safety footwear should be dictated by a clear understanding of your specific work environment and its associated risks.

- If your primary focus is impact protection (e.g., construction, logistics): Prioritize footwear with certified safety toes (steel or composite) and, if necessary, metatarsal guards.

- If your primary focus is slip prevention (e.g., food service, healthcare): The single most important feature is a high-traction, slip-resistant outsole designed for the specific surface conditions.

- If your primary focus is electrical safety (e.g., electricians, utility workers): You must select footwear explicitly designated with an Electrical Hazard (EH) rating.

- If your primary focus is a combination of hazards: Choose a shoe that carries multiple certifications to provide comprehensive, all-in-one protection.

Ultimately, investing in the correct safety footwear is a foundational pillar of a responsible and resilient operation.

Summary Table:

| Key Reason | Why It Matters |

|---|---|

| Legal Compliance | Mandatory PPE to avoid fines and legal sanctions. |

| Hazard Protection | Guards against impacts, punctures, slips, and electrical dangers. |

| Financial Risk Reduction | Prevents costly injuries, workers' comp claims, and lost productivity. |

| Enhanced Safety Culture | Demonstrates commitment to employee well-being and boosts morale. |

Ensure your workforce is fully protected and your business is compliant. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, tailored to your specific hazards and needs.

Contact us today for a consultation on building a compliant and effective safety footwear program.

Visual Guide

Related Products

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What is the purpose of puncture-resistant boots? Essential Protection for Hazardous Workplaces

- What is puncture resistance in safety footwear? Your Guide to Essential Foot Protection

- How does toe box design differ between men's and women's work boots? Fit for a Woman's Foot Anatomy

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the construction-specific OSHA footwear requirements? Choose the Right Boots for Job Site Safety