I'm thinking about it like this:

First, I need to get the audience's attention with a compelling opening that clearly answers the initial question: "Why did cowboy boots become work boots?" Then, I'll provide a concise, high-level summary as a blockquote, the critical takeaway, just to set the stage. The meat of the article will be a detailed breakdown of the evolution. I'm imagining a structure that emphasizes contrast and need. I'll describe the features of the original Western boot – the high shaft, the angled heel, the smooth sole – and explain how each was perfectly suited for horseback riding. Then, I'll shift gears to talk about the shift in work, the rise of industrialization, and how the original design proved inadequate and, even dangerous, in these new environments. This will be the need part. Finally, I'll detail the adaptations—the shift from angled to block heels, the change from smooth to lugged soles, the introduction of reinforced toes. I'll keep the whole tone authoritative yet accessible, using short paragraphs and bolding key terms. At the end, I'll offer a conclusion, providing actionable advice for choosing the right type of boot for different needs.

I want to empower the audience with a deeper understanding of the design principles at play. It's about explaining the logical connections between the original functionality, the change in working conditions, and the new design choices. I need to make the why as important as the what. This focus on the "why" will make the article stand out. The evolution from Western boot to work boot was driven entirely by necessity. As industrialization transformed the American landscape in the late 19th century, cowboys and ranchers increasingly moved into new occupations like mining, logging, and construction. The specialized riding boot, perfected for life in the saddle, was fundamentally unsuited for these hazardous environments, forcing a rapid adaptation in its design to prioritize safety and stability over equestrian performance.

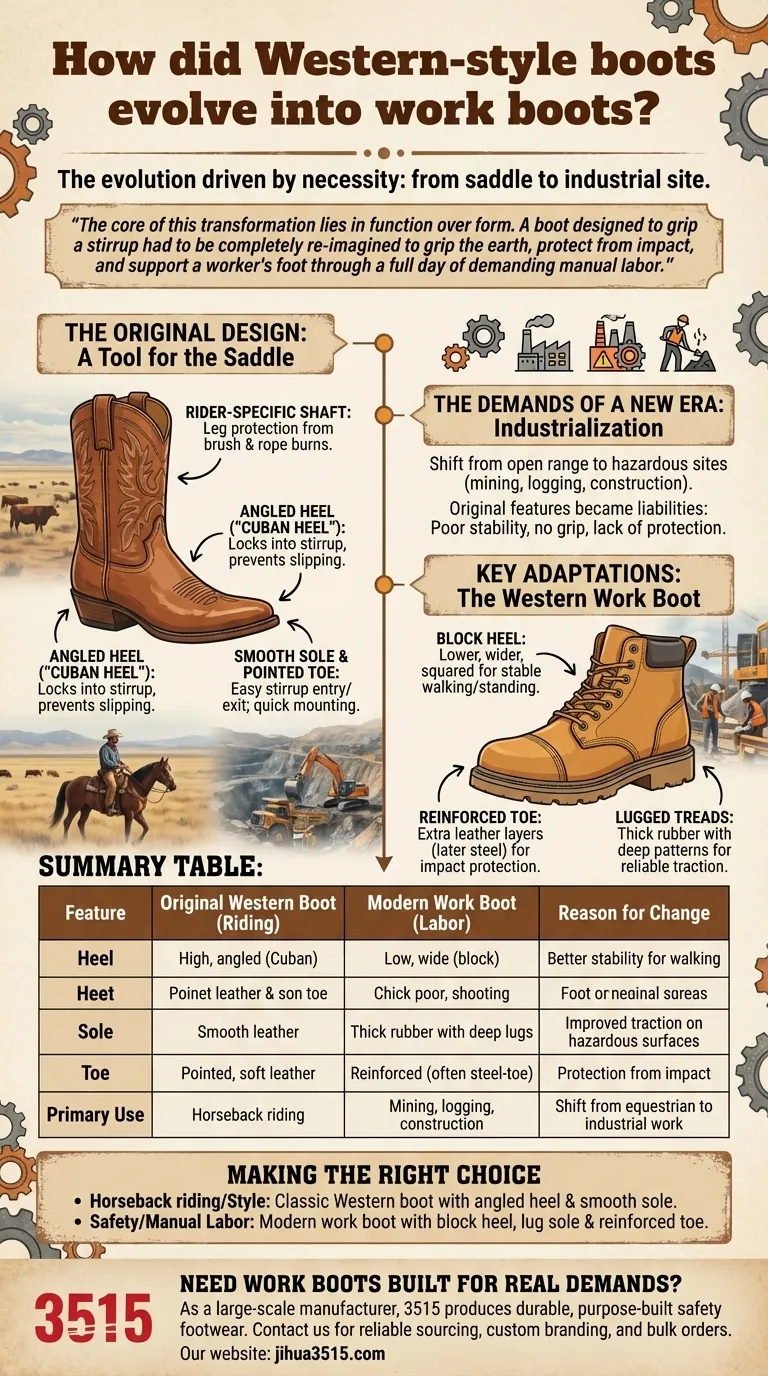

The core of this transformation lies in function over form. A boot designed to grip a stirrup had to be completely re-imagined to grip the earth, protect from impact, and support a worker's foot through a full day of demanding manual labor.

The Original Design: A Tool for the Saddle

To understand the evolution, we must first appreciate that the classic Western boot was a highly specialized piece of equipment. Every one of its iconic features served a distinct purpose related to horseback riding.

The Rider-Specific Shaft

The tall leather shaft was not a fashion statement. It was essential protection for a rider's legs against thick brush, rope burns, and other hazards encountered on the trail.

The Angled Heel

The high, angled heel, often called a "Cuban heel," was the boot's most critical safety feature. It was designed to lock into a stirrup, preventing a rider's foot from slipping forward and getting dangerously caught in the event of a fall.

The Smooth Sole

A smooth, typically leather, sole and a pointed toe allowed a rider to easily slide their foot into and out of the stirrup. On the open range, quick mounting and dismounting were far more important than ground traction.

The Demands of a New Era: Industrialization

The shift from open-range cattle driving to industrial labor sites presented a radically different set of challenges. The very features that made the Western boot ideal for riding became significant liabilities.

From Plains to Hazardous Sites

Jobs in mining, logging, and construction required long hours on foot across treacherous, uneven, and often slick surfaces. The environment was no longer about interacting with a horse, but with the raw materials of industry.

The Need for Stability and Traction

The angled, narrow heel of a cowboy boot offered poor stability for walking, while the smooth sole provided almost no grip on mud, rock, or wooden scaffolding. This made the traditional design impractical and unsafe for industrial workers.

The Imperative of Protection

The new workplaces introduced threats the original boot never had to account for. Falling tools, heavy materials, and collapsing earth created a new, urgent need for foot protection, especially around the toes.

Understanding the Trade-offs: Key Adaptations

The Western work boot was born from a series of functional compromises. Each change sacrificed an equestrian feature to gain a crucial industrial advantage.

From Angled to Block Heels

The most immediate change was the move to a lower, wider, and more squared-off block heel. This provided a much more stable platform for walking and standing, drastically reducing the risk of twisted ankles.

From Smooth Soles to Lugged Treads

Smooth leather was replaced by thick rubber with deep, aggressive patterns known as lug soles. This innovation gave workers the reliable traction needed to navigate dangerous job sites with confidence.

The Introduction of Reinforced Toes

To guard against impact and compression injuries, bootmakers began reinforcing the toe box with extra layers of leather. This was the critical first step that would eventually evolve into the modern steel-toe cap, a hallmark of safety footwear.

Making the Right Choice for Your Needs

This functional evolution directly informs the distinct boot categories available today. Selecting the right one depends entirely on your intended use.

- If your primary focus is horseback riding or historical style: The classic Western boot, with its angled heel and smooth sole, remains the superior design for interacting with a stirrup.

- If your primary focus is safety and support for manual labor: The modern work boot, with its block heel, lug sole, and reinforced toe, is the purpose-built tool you require.

Ultimately, choosing the right boot is about matching its purpose-driven design to the demands of your environment.

Summary Table:

| Feature | Original Western Boot (Riding) | Modern Work Boot (Labor) | Reason for Change |

|---|---|---|---|

| Heel | High, angled (Cuban heel) | Low, wide (block heel) | Better stability for walking and standing |

| Sole | Smooth leather | Thick rubber with deep lugs | Improved traction on hazardous surfaces |

| Toe | Pointed, soft leather | Reinforced (often steel-toe) | Protection from impact and compression |

| Primary Use | Horseback riding | Mining, logging, construction | Shift from equestrian to industrial work environments |

Need Work Boots Built for Real Demands?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, purpose-built footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots, designed to meet the rigorous demands of modern industry—just as the original work boots evolved to do.

We can help you:

- Source reliable, high-quality work boots for your customers or workforce.

- Develop custom-branded footwear tailored to specific safety standards and aesthetic requirements.

- Secure bulk orders with consistent quality and competitive pricing.

Let's discuss your footwear needs. Contact our team today to get a quote or learn more about our manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are cowboy boots and what do they represent? A Symbol of Rugged Independence and Style

- What are the key features of workwear boots? A Guide to Certified Safety and Durability

- What are the potential drawbacks of pull-on work boots? Limited Ankle Support & Fit Issues

- What are the key features of safety boots? Essential Protection for Hazardous Workplaces

- What are the essential features of fire boots? A Guide to Maximum Safety & Performance

- What features make for good quality work boots? A Guide to Durable Construction & Safety

- What maintenance steps are recommended for outsoles on work boots? Extend Boot Life & Maximize Safety

- What protective functions do industrial-grade safety boots provide in construction and mining? Maximize Worker Safety