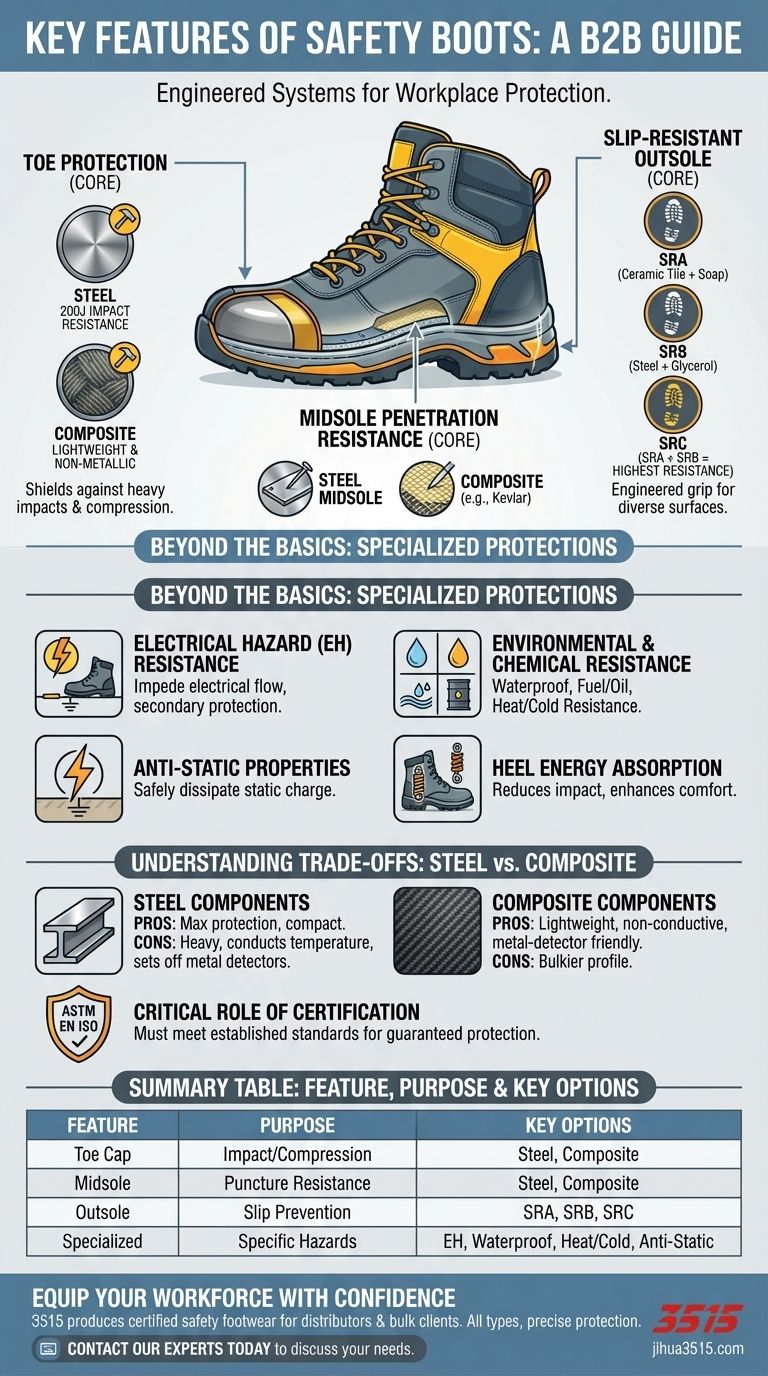

At their core, safety boots are defined by three primary features: a protective toe cap, a penetration-resistant midsole, and a slip-resistant outsole. These components are engineered to shield the wearer from the most common and severe workplace foot injuries, such as crushing impacts, punctures from below, and dangerous falls.

The key to understanding safety boots is to see them not as a single product, but as a system of specialized protections. The right boot is the one whose features directly counter the specific hazards present in your work environment.

Core Protective Components Explained

Every certified safety boot is built upon a foundation of non-negotiable protective elements. These features address the most immediate and universal risks to foot safety in hazardous workplaces.

Toe Protection: The First Line of Defense

The most recognizable feature is the protective toe cap, designed to resist a 200-joule impact. This is the standard for protection against heavy falling objects and compression hazards.

These caps are typically made from steel or composite materials. Both must meet the same rigorous safety standards to be certified.

Midsole Penetration Resistance

To protect against sharp objects piercing the boot from below, a protective plate is embedded in the midsole. This is crucial on sites with nails, screws, or other sharp debris.

Like toe caps, these midsoles can be made of steel or flexible composite materials like Kevlar.

Slip-Resistant Outsoles

Slips, trips, and falls are among the most frequent workplace accidents. Safety boot outsoles are rated for their grip on specific surfaces.

The ratings indicate performance:

- SRA: Tested and passed on ceramic tile wetted with a soap solution.

- SRB: Tested and passed on smooth steel with glycerol.

- SRC: Passed both SRA and SRB tests, offering the highest level of slip resistance.

Beyond the Basics: Specialized Protections

Beyond the core components, many safety boots incorporate features designed for specific environmental or electrical hazards, tailoring the protection to the job.

Electrical Hazard (EH) Resistance

EH-rated boots are designed to impede the flow of electricity through the boot to the ground. This feature offers a secondary source of protection against accidental contact with live electrical circuits.

Environmental and Chemical Resistance

Many boots are designed to handle specific environmental challenges. This includes waterproof membranes for wet conditions and resistance to substances like fuel and oil.

For extreme temperatures, boots can be made with heat-resistant outsoles or include cold insulation for work in freezers or winter conditions.

Anti-Static Properties

In environments where a buildup of static electricity could damage sensitive electronic components or ignite flammable materials, anti-static boots are essential. They safely dissipate static charge into the ground.

Heel Energy Absorption

This feature reduces the force of impact on the wearer's heel when walking. It significantly enhances comfort and reduces fatigue and the risk of musculoskeletal injury over a long shift.

Understanding the Trade-offs: Steel vs. Composite

The choice between steel and composite materials for toe caps and midsoles is a critical decision based on your specific needs and environment.

The Case for Steel

Steel components offer maximum protection in a thin, compact profile. They are often the standard in heavy construction and manufacturing where the risk of severe impact and crushing is highest.

However, steel is heavy and conducts temperature, making it potentially uncomfortable in extreme hot or cold environments. It will also set off metal detectors.

The Case for Composite

Composite materials (like fiberglass, carbon fiber, or Kevlar) are significantly lighter than steel, reducing fatigue. They do not conduct electricity or temperature, making them ideal for electricians or those working outdoors.

Because they are non-metallic, they are the preferred choice for high-security environments with metal detectors, such as airports or government facilities.

The Critical Role of Certification

Regardless of the material, the most important feature is official certification. A boot must be tested to meet established safety standards (like ASTM or EN ISO standards). Uncertified footwear offers no guaranteed protection.

How to Select the Right Safety Boot

Choosing the correct boot means matching its features directly to the hazards you face.

- If your primary focus is heavy industry or construction: You need a boot with a certified steel or composite toe cap and a penetration-resistant midsole.

- If your primary focus is working on wet or oily surfaces: Prioritize a boot with an SRC-rated slip-resistant outsole.

- If your primary focus is working near live electrical circuits: You must select a boot that is explicitly EH-rated.

- If your primary focus is comfort, temperature extremes, or security checkpoints: Choose a boot made with lightweight composite protective components.

Ultimately, selecting the right safety boot is a critical risk assessment that treats your footwear as an essential piece of specialized equipment.

Summary Table:

| Feature | Purpose | Key Options |

|---|---|---|

| Toe Cap | Protects against impact and compression. | Steel, Composite (e.g., fiberglass). |

| Midsole | Resists punctures from sharp objects. | Steel, Composite (e.g., Kevlar). |

| Outsole | Prevents slips and falls. | SRA, SRB, SRC slip resistance ratings. |

| Specialized | For specific hazards like electricity or extreme temperatures. | EH Rating, Waterproofing, Heat/Cold Resistance, Anti-Static. |

Equip Your Workforce with Confidence

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, ensuring your team has the precise protection they need.

Let us help you mitigate workplace risks. Contact our experts today to discuss your specific requirements and discover how 3515 can be your reliable partner in safety.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What styles can safety toe work boots come in? From Classic to Casual, Find Your Perfect Fit

- What are the common materials used in the upper part of light work boots? Find the Perfect Balance of Durability & Comfort

- What should be considered when sizing and fitting engineer boots? Master the Laceless Fit for Maximum Comfort

- What are the advantages of specialty protective boots in emergency rescue? Optimize Rail Transit Safety & Command

- How do work boots impact the physiological heat load of laborers? Understanding Heat Stress in High Temperatures

- Why is high-quality leather a common material for firefighter boots? Unmatched Protection & Durability

- What are the requirements for wildland firefighter boots? Ensure NFPA 1977 Compliance for Ultimate Safety

- How do men's winter work boots differ from casual boots? Choose the Right Footwear for Safety & Style