Proper outsole maintenance is a straightforward but critical process. The recommended steps involve daily cleaning with a soft brush and, when necessary, mild soap and warm water. It is essential to let the boots dry naturally away from direct heat and to conduct regular inspections for embedded objects or signs of excessive wear.

Maintaining your work boot outsoles is not merely cosmetic. It is a fundamental safety practice that directly preserves their grip, structural integrity, and protective capabilities, ensuring they function as intended in demanding environments.

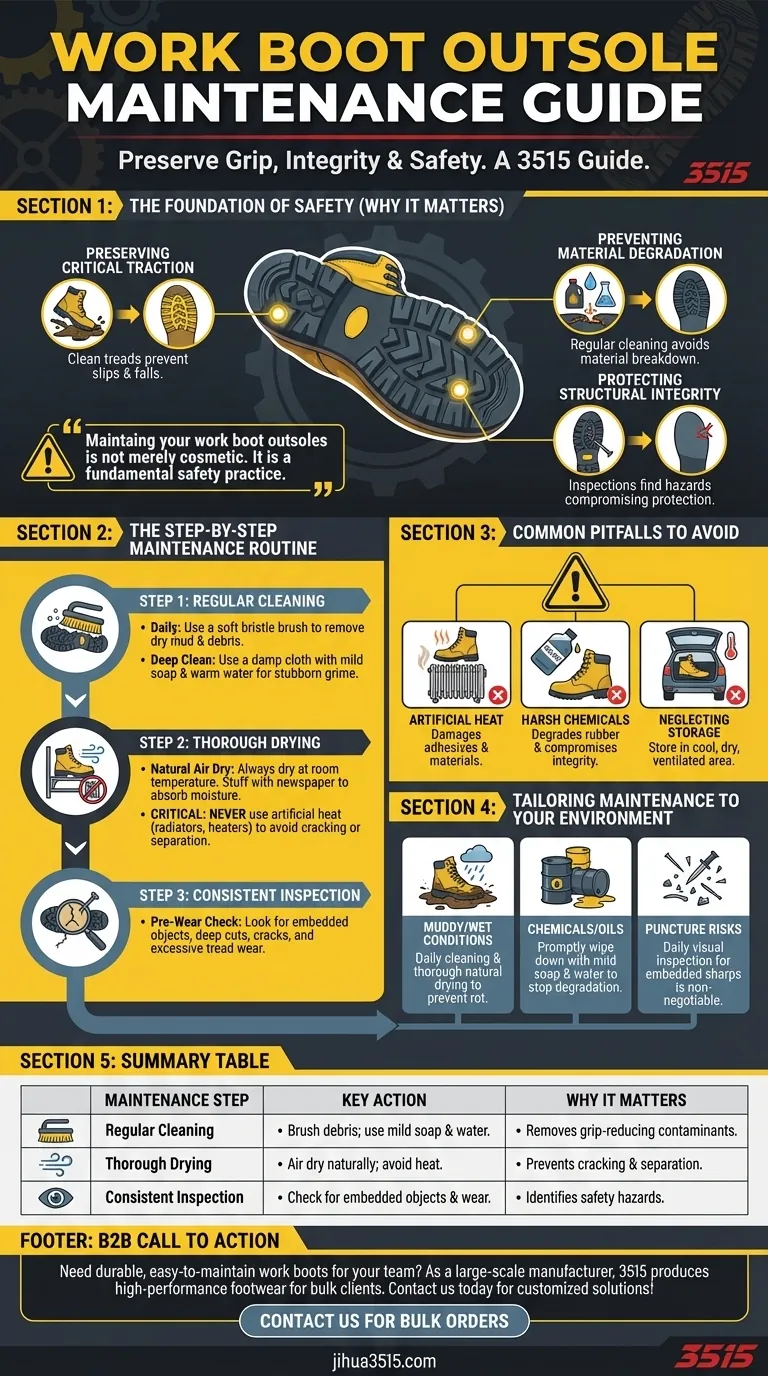

The Foundation of Safety: Why Outsole Care Matters

The outsole is your primary point of contact with your work surface, making its condition directly responsible for your safety and stability. Proper care is about preserving its core functions.

Preserving Critical Traction

Caked-on mud, grease, or other debris fills the tread pattern of the outsole. This effectively smooths the surface, drastically reducing its ability to grip and increasing the risk of slips and falls.

Preventing Material Degradation

Outsoles are exposed to a variety of substances, from water and mud to oils and chemicals. Regular cleaning removes these contaminants, which can otherwise break down the rubber or synthetic compounds over time, making them brittle or soft.

Protecting Structural Integrity

Work boot soles are designed to be thick and durable to resist punctures. A quick inspection can reveal embedded nails, glass, or sharp metal fragments that compromise this protective barrier.

The Step-by-Step Maintenance Routine

Integrating a simple routine into your daily schedule is the most effective way to extend the life and performance of your boots.

Step 1: Regular Cleaning

After each use, use a soft bristle brush to dislodge any dry mud and debris from the tread.

For more stubborn grime, use a damp cloth with a solution of mild soap and warm water. This is effective for removing most common contaminants without damaging the sole material.

Step 2: Thorough Drying

If your boots get wet, always allow them to dry naturally at room temperature. Stuffing them with newspaper can help absorb internal moisture and maintain their shape.

This is a critical step. Never use artificial heat sources like radiators, heaters, or blow dryers, as intense heat can cause the sole materials to crack, harden, or separate from the boot upper.

Step 3: Consistent Inspection

Before putting on your boots, perform a quick visual inspection of the outsoles. Look for embedded objects, check for deep cuts or cracks, and note any areas where the tread is becoming excessively worn down.

Common Pitfalls to Avoid

Simple mistakes can significantly shorten the lifespan of your work boots. Being aware of them is as important as knowing the proper maintenance steps.

The Danger of Artificial Heat

This is the most common and damaging mistake. Direct heat compromises the adhesives that bond the sole to the boot and can irrevocably damage the sole's material composition.

Using Harsh Chemicals

Avoid cleaning your outsoles with industrial solvents, degreasers, or harsh detergents unless the boot manufacturer specifically states they are safe. These chemicals can degrade the rubber and compromise its integrity.

Neglecting Proper Storage

Do not store your boots in extreme temperatures, such as a hot vehicle trunk or a damp, unventilated locker. A cool, dry, and well-ventilated area is ideal for preserving all components of the boot.

Tailoring Maintenance to Your Environment

Your specific work conditions should guide your maintenance priorities.

- If you work in muddy or wet conditions: Make daily cleaning and thorough, natural drying your top priority to prevent material rot and maintain traction.

- If you work around chemicals or oils: Focus on wiping down the soles promptly with mild soap and water to stop chemical reactions that degrade the material.

- If your primary concern is puncture resistance: Make a daily visual inspection for embedded sharp objects a non-negotiable part of your routine.

A few minutes of consistent care ensures your boots can protect you effectively throughout their intended lifespan.

Summary Table:

| Maintenance Step | Key Action | Why It Matters |

|---|---|---|

| Regular Cleaning | Brush off debris; use mild soap & water. | Removes contaminants that reduce grip and degrade material. |

| Thorough Drying | Air dry naturally; avoid direct heat. | Prevents cracking, hardening, and sole separation. |

| Consistent Inspection | Check for embedded objects and wear. | Identifies potential safety hazards and structural damage. |

Need durable, easy-to-maintain work boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our expertise ensures your boots are built to last in any environment. Contact us today to discuss your specific needs and receive a customized solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are some ways to enhance an outfit with moc toe boots? Master Rugged, Smart-Casual & Modern Styles

- What are the main safety features of mining boots? Essential Protection for Harsh Environments

- How easy is it to maintain PVC work boots? The Ultimate Guide to Simple Care & Trade-offs

- Why should you avoid using products with lanolin on leather boots? Preserve Boot Structure and Durability

- Why are waterproof and breathable properties important in farming and gardening boots? The Key to All-Day Comfort and Foot Health

- How have cowboy boots evolved over time? From functional gear to fashion icon

- Why should employers require high-quality work-safe boots? Boost Safety & Productivity Now

- What industries is this boot designed for? Ideal for Oil & Gas and Chemical Manufacturing