The defining features of a true workwear boot are not just about style or material; they are a system of engineered components designed for safety, support, and durability. These boots are defined by certified protective elements like steel or composite toes, slip-resistant outsoles, and high-cut designs that provide crucial ankle support for demanding physical environments.

The most critical feature of any work boot is its safety certification. A boot without verified protection against job-specific hazards like impact, puncture, or electrical shock is not a work boot—it is simply a boot that fails to meet the fundamental requirement of its category.

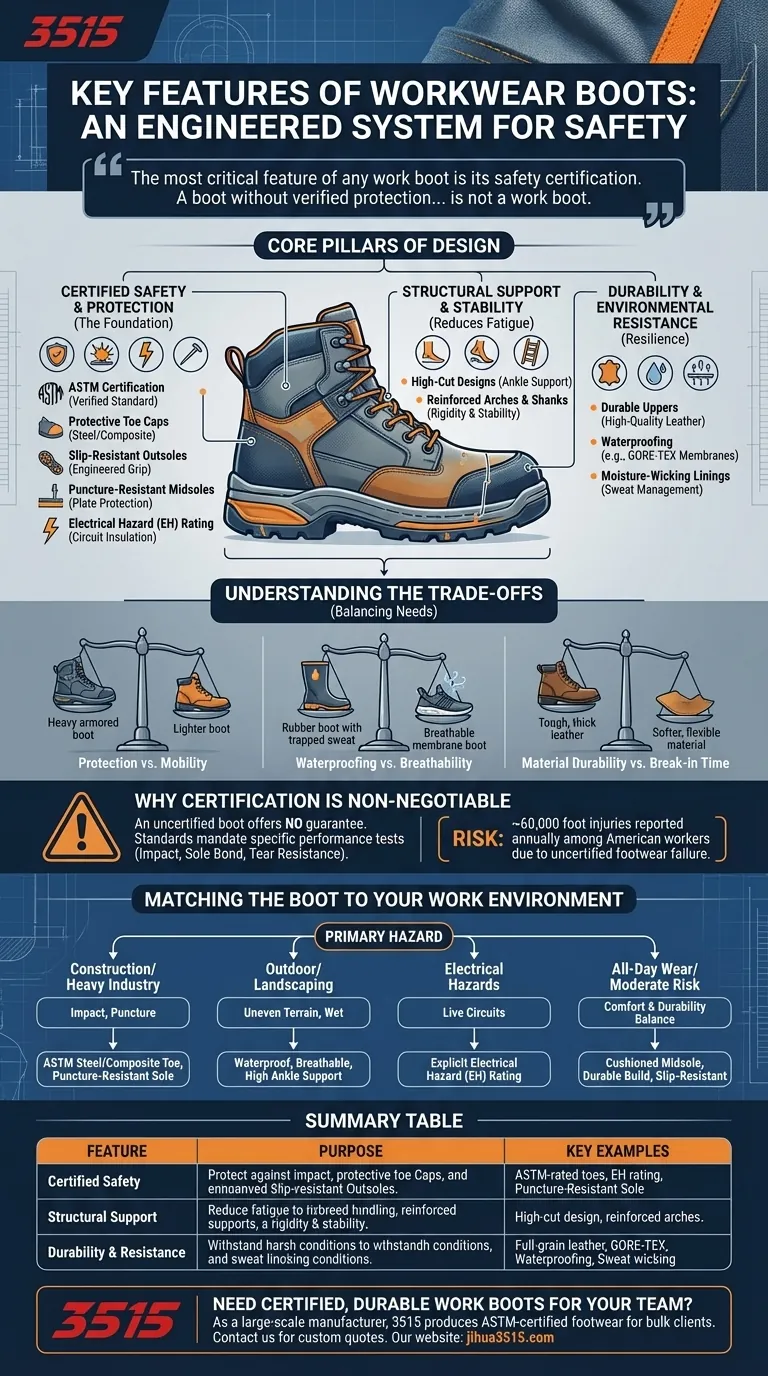

The Core Pillars of Work Boot Design

A work boot is a piece of personal protective equipment (PPE). Each feature serves a distinct purpose, working together to prevent injury and provide stability throughout the workday.

Certified Safety and Protection

This is the non-negotiable foundation of any work boot. These features are tested and rated against established industry standards.

ASTM Certification is the mark of a legitimate safety boot. It signifies that the boot has passed rigorous tests for impact resistance, compression, and other protective qualities outlined by organizations like the American Society for Testing and Materials.

Protective Toe Caps shield the foot from falling objects and compression. Steel toes offer maximum protection, while composite toes are lighter, do not conduct temperature, and are ideal for metal-free environments.

Slip-Resistant Outsoles are critical for preventing falls. They are engineered with specific tread patterns and materials to provide a solid grip on wet, oily, or uneven surfaces.

Puncture-Resistant Midsoles, often made of steel or composite plates, protect the bottom of the foot from sharp objects like nails or scrap metal.

Electrical Hazard (EH) Rating indicates the boot provides a secondary source of protection from live electrical circuits, insulating the wearer from the ground.

Structural Support and Stability

Proper support reduces fatigue and prevents common injuries like sprains and twists, which are frequent on uneven job sites.

High-Cut Designs are standard for work boots because they wrap around the ankle, providing essential support and protecting against abrasions.

Reinforced Arches and shanks offer rigidity to the midfoot. This is especially important for tasks that involve climbing ladders, as it prevents the boot from collapsing under your weight.

Durability and Environmental Resistance

Work boots must withstand harsh conditions day after day. The materials and construction methods are chosen for resilience.

Durable Uppers, typically made from high-quality leather, resist moisture and abrasions while conforming to the foot over time.

Waterproofing is essential for outdoor work. Technologies like GORE-TEX membranes create a barrier that keeps feet dry from external elements like rain and mud.

Moisture-Wicking Linings manage sweat on the inside of the boot, pulling moisture away from the skin to keep feet dry and prevent blisters.

Understanding the Trade-offs

Choosing the right boot involves balancing competing needs. No single boot is perfect for every task, and understanding the trade-offs is key to making an informed decision.

Protection vs. Mobility

Heavily armored boots with thick soles and steel components offer maximum protection but can be heavy and stiff, potentially reducing agility. Lighter boots may offer more flexibility at the cost of some protective features.

Waterproofing vs. Breathability

Fully waterproof boots, such as those made of rubber, are excellent at keeping water out but can also trap sweat and heat, leading to discomfort. Breathable waterproof membranes are a common solution, but a trade-off still exists.

Material Durability vs. Break-in Time

Tough, thick leather boots provide exceptional durability but often require a significant break-in period. Softer, more flexible materials may be comfortable out of the box but may not hold up as long under intense use.

Why Certification Is Non-Negotiable

The importance of official safety ratings cannot be overstated. An uncertified boot offers no guarantee of protection, regardless of its appearance.

The Role of PPE Standards

Official standards mandate specific performance tests. These include impact tests for the toe cap, sole bond testing to ensure the boot doesn't fall apart, and tear resistance tests for the upper material.

The Risks of Uncertified Footwear

With approximately 60,000 foot injuries reported annually among American workers, wearing uncertified footwear is a significant gamble. These boots can fail under stress, leading directly to the punctures, broken bones, or electrical shocks they are meant to prevent.

Matching the Boot to Your Work Environment

Use the primary hazards of your job to guide your selection.

- If your primary focus is construction or heavy industry: Prioritize an ASTM-certified steel or composite toe for impact protection and a puncture-resistant sole.

- If your primary focus is outdoor work like landscaping: Emphasize a waterproof and breathable design with excellent ankle support for navigating uneven terrain.

- If your primary focus is work around electrical hazards: Ensure the boot has a specific Electrical Hazard (EH) rating clearly stated by the manufacturer.

- If your primary focus is all-day wear with moderate risk: Look for a balance of comfort, such as a cushioned midsole, with a durable build and a reliable slip-resistant outsole.

Investing in the right certified work boot is a direct investment in your personal safety and daily performance.

Summary Table:

| Feature | Purpose | Key Examples |

|---|---|---|

| Certified Safety | Protect against impact, puncture, and electrical hazards | ASTM-rated steel/composite toes, EH rating, puncture-resistant midsoles |

| Structural Support | Reduce fatigue and prevent ankle injuries | High-cut ankle design, reinforced arches, rigid shanks |

| Durability & Resistance | Withstand harsh conditions and extend boot life | Full-grain leather uppers, waterproof membranes (e.g., GORE-TEX), moisture-wicking linings |

Need certified, durable work boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure safety, comfort, and long-lasting performance tailored to your industry's demands. Contact us today to discuss your bulk order requirements and get a custom quote!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What materials are used in Chemical Resistant boots for additional protection? Choose the Right Defense for Your Workplace

- What makes moc toe boots suitable for workers with wide feet? Superior Comfort for Wide Feet

- Why is electrical hazard protection required on some job sites? Essential Safety for High-Risk Environments

- What is the purpose of the midsole in work boots? Enhance Comfort, Safety & Durability

- What is Thinsulate and how does it function in insulated boots? Achieve Superior Warmth Without Bulk

- What is the impact of improper boot lacing on boot longevity? Maximize Durability with Proper Care

- How are women's work boots designed differently? Engineered for a Woman's Foot Anatomy

- What distinguishes heavy duty work boots from regular boots? Safety, Durability & Purpose Explained