A quality work boot is a purpose-built system combining durable materials, job-specific safety features, and foundational support. The best boots are defined by their construction, such as using full-grain leather and a Goodyear welt, and integrate certified safety components like protective toe caps and slip-resistant outsoles to ensure both longevity and user safety.

Choosing a work boot isn't about finding one with the most features; it's about matching the boot's construction and safety ratings to the specific demands of your work environment. The right boot is a calculated balance of protection, support, and long-term comfort for your daily tasks.

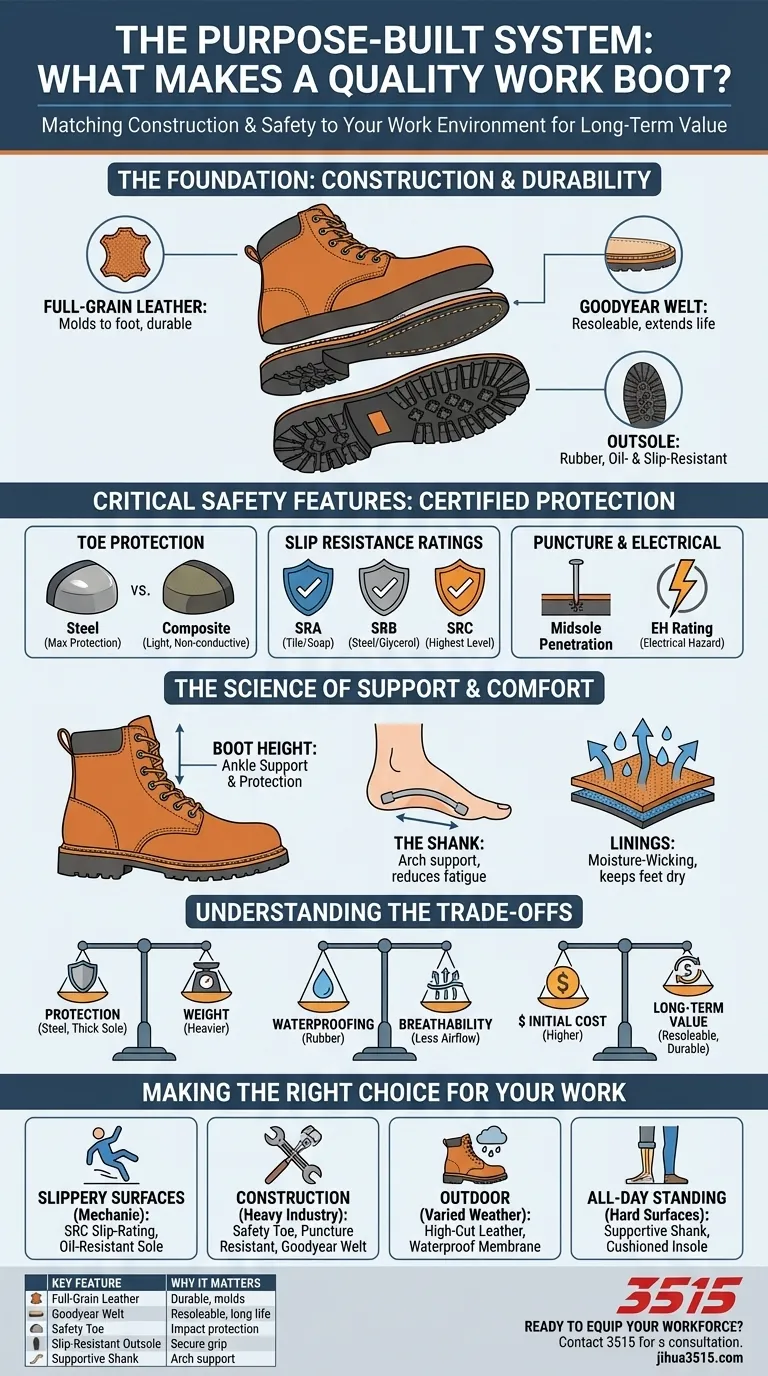

The Foundation: Construction and Durability

The materials and construction method determine a boot's lifespan and its ability to withstand daily abuse.

Full-Grain Leather: The Gold Standard

Full-grain leather is the highest quality grade available. It is prized for its exceptional durability, moisture resistance, and ability to mold to your foot over time for a custom fit.

Goodyear Welt Construction: A Sign of Longevity

This construction method stitches the boot's upper to the sole, creating a highly durable and water-resistant seam. Critically, it allows the boot to be resoled, dramatically extending its usable life far beyond boots with glued-on soles.

The Outsole: Your Connection to the Ground

The outsole should be made from a durable material like rubber, often with deep treads for traction. A key feature for many industries is an oil- and slip-resistant rating, which provides a secure grip on slick surfaces.

Critical Safety Features Explained

Safety features are not optional accessories; they are certified components designed to protect you from specific workplace hazards.

Toe Protection: Steel vs. Composite

Protective toe caps are essential in environments with a risk of impact or compression. Steel toes offer maximum protection, while composite toes (made from materials like Kevlar or carbon fiber) are lighter and do not conduct electricity or cold. Both must meet standardized safety ratings, such as a 200-joule impact resistance.

Slip Resistance Ratings

A sole's slip resistance is tested and certified. Look for these ratings:

- SRA: Tested and passed on ceramic tile wetted with soap solution.

- SRB: Tested and passed on smooth steel with glycerol.

- SRC: Passed both SRA and SRB tests, offering the highest level of slip resistance.

Puncture and Electrical Hazard Protection

For protection against sharp objects from below, look for midsole penetration resistance. For electricians or those working near live circuits, boots with an Electrical Hazard (EH) rating provide crucial insulation.

The Science of All-Day Support and Comfort

Protection is meaningless if the boot is too uncomfortable to wear. Key structural elements are designed to fight fatigue and provide stability.

Boot Height and Ankle Support

A higher-cut boot, or longer shaft, provides essential support to the ankle. This helps prevent twists and sprains while also protecting the lower leg from abrasions.

The Shank: The Unseen Backbone

A shank is a rigid piece of material (often steel) placed between the insole and outsole. It provides crucial arch support, distributes weight evenly, and reduces the strain on your feet, especially when climbing ladders or standing for long periods.

Linings and Moisture Management

Feet sweat, which can lead to blisters and discomfort. A quality boot uses moisture-wicking linings to pull perspiration away from the skin, keeping your feet dry and comfortable throughout the day.

Understanding the Trade-offs

No single boot is perfect for every job. Choosing the right one requires understanding the inherent compromises.

Protection vs. Weight

Features like steel toes and thick rubber outsoles add significant protection but also increase the boot's weight. For jobs requiring constant movement, a lighter composite toe and more flexible sole might be a better, albeit less protective, choice.

Waterproofing vs. Breathability

Fully waterproof boots, like those made of rubber, are excellent for wet and muddy conditions but offer almost no breathability. A boot with a waterproof membrane and leather upper offers a compromise, keeping water out while allowing some perspiration to escape.

Initial Cost vs. Long-Term Value

A boot with a Goodyear welt and full-grain leather will cost more upfront. However, its durability and ability to be resoled often make it a more economical choice over several years compared to replacing cheaper, glued-sole boots annually.

Making the Right Choice for Your Work

Match the features directly to the hazards and demands of your job.

- If your primary focus is working on slippery surfaces (e.g., mechanic, factory floor): Prioritize a boot with an SRC slip-rating and an oil-resistant rubber outsole.

- If your primary focus is construction or heavy industry: A certified steel or composite toe, midsole puncture resistance, and a durable Goodyear welt are non-negotiable.

- If your primary focus is outdoor work in varied weather: Look for a high-cut leather boot with a waterproof membrane and moisture-wicking linings.

- If your primary focus is all-day standing on hard surfaces: A supportive shank and a high-quality, cushioned insole are critical for preventing foot fatigue.

Investing in the right features ensures your boots will work as hard as you do, providing the protection and comfort you need day after day.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| Full-Grain Leather | Superior durability, moisture resistance, and molds to your foot. |

| Goodyear Welt | Allows for resoling, dramatically extending the boot's lifespan. |

| Safety Toe (Steel/Composite) | Certified protection from impact and compression hazards. |

| Slip-Resistant Outsole (SRA/SRB/SRC) | Provides a secure grip on slick, oily, or wet surfaces. |

| Supportive Shank | Offers crucial arch support and reduces foot fatigue. |

Ready to equip your workforce with purpose-built footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-performance work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, from construction-grade boots with steel toes to lightweight composite options for electricians.

We ensure every pair meets the highest standards of protection, comfort, and longevity. Let us help you find the perfect boot for your specific industry needs.

Contact us today for a consultation and discover the 3515 difference!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- How do composite toe work boots provide protection without the weight of steel? Achieve Lighter, Safer Footwear

- What is metatarsal guard protection in mining boots? Essential Safety for Heavy Industry

- How does rebuildability extend the life of fire boots? Maximize Your Gear's Lifespan & ROI

- What are the different styles of women's work boots available? Find Your Perfect Fit for Safety & Comfort

- What should be considered regarding stiffness after wax treatment? A Trade-Off for Durability

- What are the key roles of work boots in labor-intensive jobs? Essential for Safety, Performance & Comfort

- What type of boots are recommended for proximity and structural firefighters? Secure Fit for Maximum Stability

- Why are lace-to-toe boots popular among wildland firefighters? Achieve Unmatched Stability and Safety