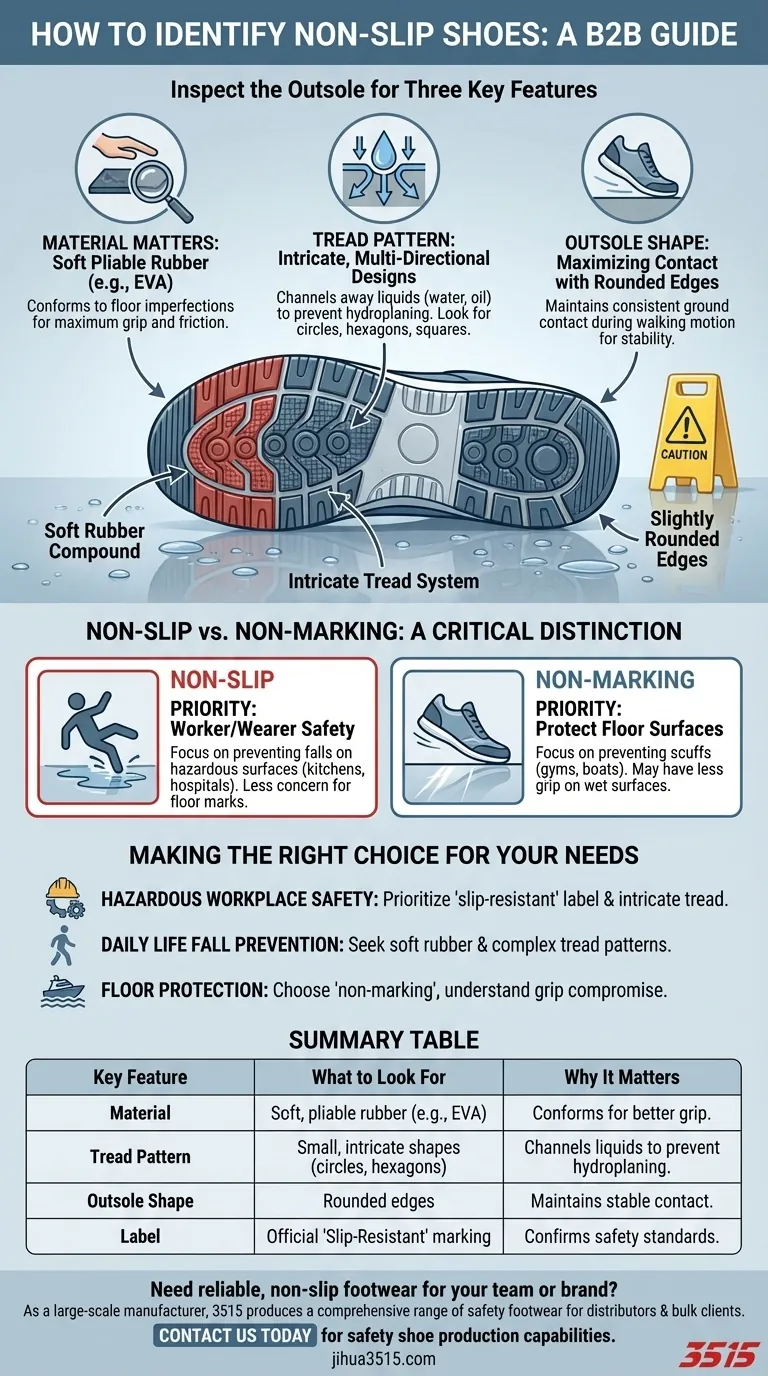

To identify non-slip shoes, you must inspect the outsole for three key features. Look for an official "slip-resistant" label, examine the tread for small, intricate patterns like circles or hexagons, and confirm the sole is made of a soft, pliable rubber designed to grip surfaces. These elements work together to provide stability on wet or oily floors.

True slip resistance is not a single feature but a system. It relies on the interplay between the sole's material, its tread pattern, and its overall shape to actively channel away liquids and maximize contact with the ground.

The Anatomy of a Slip-Resistant Sole

Understanding why certain features create grip empowers you to look beyond marketing claims and assess a shoe's true safety potential. The magic happens entirely in the outsole, the part of the shoe that contacts the floor.

Material Matters: The Role of Soft Rubber

The material of the outsole is your first clue. Effective non-slip shoes use a soft rubber compound, sometimes specified as EVA rubber.

Unlike hard, rigid plastics, soft rubber can better conform to microscopic imperfections in a floor's surface. This flexibility creates more surface area for contact, which in turn generates greater friction and grip.

Tread Pattern: The Key to Channeling Liquid

The tread pattern is the most critical visual indicator of a non-slip shoe. It is engineered to prevent hydroplaning, where a layer of liquid gets trapped between the shoe and the floor.

Look for small, intricate, and multi-directional patterns. Small circles, squares, or hexagons are common. These small shapes create an open-channel system that quickly pushes water, oil, and other liquids out from under the shoe, allowing the rubber to make direct, solid contact with the floor.

Outsole Shape: Maximizing Contact

The overall design of the outsole also contributes to stability. Many slip-resistant soles feature slightly rounded edges.

This design helps maintain consistent contact with the ground as your foot rolls forward during a normal walking motion. Flat, hard edges can create a tipping point, whereas a rounded design provides a smoother and more stable transfer of weight.

A Common Point of Confusion: Non-Slip vs. Non-Marking

It is crucial to understand that "non-slip" and "non-marking" are two entirely different features that are often confused. Choosing the wrong one can compromise either safety or floor integrity.

What "Non-Slip" Prioritizes

A non-slip shoe is designed for one primary purpose: worker or wearer safety. Its entire design focuses on preventing falls on hazardous surfaces like wet kitchen floors, oily garage bays, or slick hospital corridors.

What "Non-Marking" Prioritizes

A non-marking shoe is designed to protect floor surfaces. These are common for boating, racquetball, or gym use where black scuff marks are undesirable. Their soles are typically made of a softer material that doesn't leave residue, but they often feature minimal treads, which makes them less effective on wet or slippery surfaces.

Making the Right Choice for Your Needs

Use this framework to select the appropriate shoe based on your primary requirement.

- If your primary focus is safety in a hazardous workplace: Prioritize shoes explicitly labeled "slip-resistant" and verify they have an intricate, multi-channel tread pattern.

- If your primary focus is preventing falls in daily life: Look for shoes with soft rubber outsoles and a tread pattern that is more complex than simple straight lines.

- If your primary focus is protecting floors (e.g., for a gym or boat): Seek out shoes specifically labeled "non-marking" and understand that this may come at the cost of maximum grip on wet surfaces.

By evaluating a shoe's fundamental design rather than just its label, you can make an informed choice that truly meets your safety needs.

Summary Table:

| Key Feature | What to Look For | Why It Matters |

|---|---|---|

| Material | Soft, pliable rubber (e.g., EVA) | Conforms to floor surfaces for better grip and friction. |

| Tread Pattern | Small, intricate shapes (circles, hexagons) | Channels liquids away to prevent hydroplaning. |

| Outsole Shape | Rounded edges | Maintains ground contact during movement for stability. |

| Label | Official "Slip-Resistant" marking | Confirms the shoe meets specific safety standards. |

Need reliable, non-slip footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear designed for maximum slip resistance. We provide durable, compliant shoes and boots for distributors, brand owners, and bulk clients, ensuring safety and performance in demanding environments.

Contact us today to discuss your specific needs and explore our production capabilities for all types of safety shoes and boots.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- What are the durability features of slip-resistant shoes? A Guide to Long-Lasting Safety Footwear

- How do non-slip shoes benefit restaurant workers' health and finances? A Vital Investment for Safety and Stability

- Why is outsole design important for non-slip shoes? Unlock the Key to Ultimate Slip Resistance

- Why are chemical cleaners containing surfactants used in slip-resistant footwear research? Achieve Critical Safety.

- What should you do if you're unsure about a shoe's slip resistance? Ensure Your Safety with Expert Verification

- How can you perform a slip test on shoes you already own? A Guide to Safer Footwear

- Why is friction coefficient testing on wet surfaces essential? Science-Backed Slip Resistance Secrets

- What are the risks of not wearing slip-resistant shoes? Avoid Costly Injuries and Lost Productivity