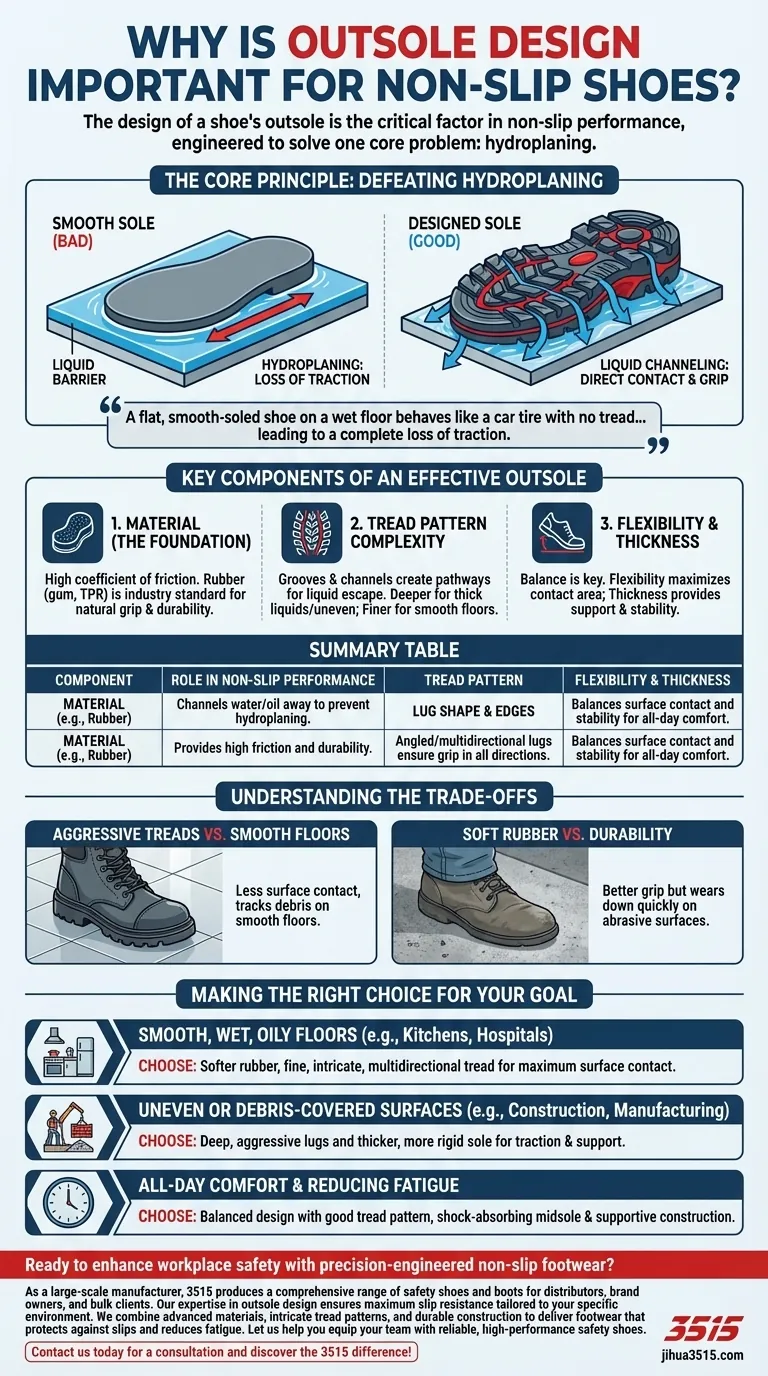

The design of a shoe's outsole is the single most critical factor in its non-slip performance because it is engineered to solve one core problem: hydroplaning. Angled edges and intricate tread patterns work together to actively channel water, oil, and other liquids out from underneath the sole, ensuring the shoe's material maintains direct contact with the ground for maximum grip.

A flat, smooth-soled shoe on a wet floor behaves like a car tire with no tread—it floats on a thin film of liquid, leading to a complete loss of traction. The specific design of a non-slip outsole creates an escape route for that liquid, which is the fundamental principle that prevents slips and falls.

The Core Principle: Defeating the Liquid Barrier

To understand why outsole design is so important, you must first understand the physics of a slip. It's rarely the surface itself that is slick; it's the liquid on top of it.

The Hydroplaning Effect

When you step on a wet or oily surface, a thin layer of liquid can become trapped between your shoe and the floor.

This trapped liquid can lift the sole, eliminating the friction needed to stay upright. This is hydroplaning, and it's the primary cause of slips on contaminated surfaces.

The Role of Tread Patterns

The grooves, channels, and lugs that make up a shoe's tread pattern are not for decoration. Their function is to create pathways for liquid to escape.

As you put weight on the shoe, the pressure forces the liquid into these channels and away from the sole's contact points, allowing the rubber to grip the floor directly.

Why Edge and Lug Shape Matters

Effective non-slip designs feature angled or rounded edges on their lugs. This prevents liquid from getting sealed under the sole's perimeter.

Multidirectional lugs provide grip no matter which way you move, turn, or pivot, which is essential in dynamic work environments.

Key Components of an Effective Outsole

While the principle is simple, executing it involves a careful combination of design, material, and construction.

Material Is the Foundation

The best design in the world won't work with the wrong material. Non-slip shoes rely on materials with a high coefficient of friction.

Rubber, particularly gum rubber or thermoplastic rubber (TPR), is the industry standard due to its excellent natural grip and durability.

Tread Pattern Complexity

Deeper, more aggressive tread patterns are excellent for channeling away thicker liquids or maintaining grip on uneven terrain.

Finer, more intricate patterns increase the surface area of the sole that can make contact with smooth floors, which is ideal for environments like commercial kitchens.

Flexibility and Thickness

An effective outsole must have a balance of flexibility and stability.

Flexibility allows the shoe to conform to the walking surface, maximizing the contact area for better grip. However, too much flexibility can compromise the support needed for long shifts, leading to fatigue.

Understanding the Trade-offs

There is no single "best" outsole design for every situation. The ideal choice always depends on the specific environment.

Aggressive Treads vs. Smooth Floors

A shoe with deep, rugged lugs designed for outdoor terrain may actually have less surface contact on a smooth tile floor, slightly reducing its grip. These deep treads can also track more dirt and debris.

Soft Rubber vs. Durability

Softer rubber compounds often provide the best possible grip, as they are more pliable and can create more friction.

The downside is that these softer materials wear down much more quickly, especially on abrasive surfaces like concrete.

Water Resistance vs. Breathability

While not part of the outsole itself, upper materials that are water-resistant keep your feet dry, which is critical for comfort and preventing skin issues. However, this can sometimes come at the cost of breathability, leading to heat and moisture buildup inside the shoe.

Making the Right Choice for Your Goal

Selecting the correct non-slip shoe requires matching the outsole's features to your specific work environment and daily tasks.

- If your primary focus is working on smooth, wet, or oily floors (e.g., kitchens, hospitals): Look for softer rubber soles with fine, intricate, and multidirectional tread patterns to maximize surface contact and channel away thin liquids.

- If your primary focus is stability on uneven or debris-covered surfaces (e.g., construction, manufacturing): Prioritize shoes with deep, aggressive lugs and a thicker, more rigid sole for maximum traction and foot support.

- If your primary focus is all-day comfort and reducing fatigue: Seek a balanced design that combines a good tread pattern with a shock-absorbing midsole and a supportive overall construction.

Ultimately, understanding the engineering behind an outsole empowers you to choose true safety, not just a label.

Summary Table:

| Key Component | Role in Non-Slip Performance |

|---|---|

| Tread Pattern | Channels water/oil away from sole to prevent hydroplaning. |

| Material (e.g., Rubber) | Provides high friction and durability for reliable grip. |

| Lug Shape & Edges | Angled/multidirectional lugs ensure grip in all directions. |

| Flexibility & Thickness | Balances surface contact and stability for all-day comfort. |

Ready to enhance workplace safety with precision-engineered non-slip footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our expertise in outsole design ensures maximum slip resistance tailored to your specific environment—whether for kitchens, hospitals, construction, or manufacturing.

We combine advanced materials, intricate tread patterns, and durable construction to deliver footwear that protects against slips and reduces fatigue. Let us help you equip your team with reliable, high-performance safety shoes.

Contact us today for a consultation and discover the 3515 difference!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management