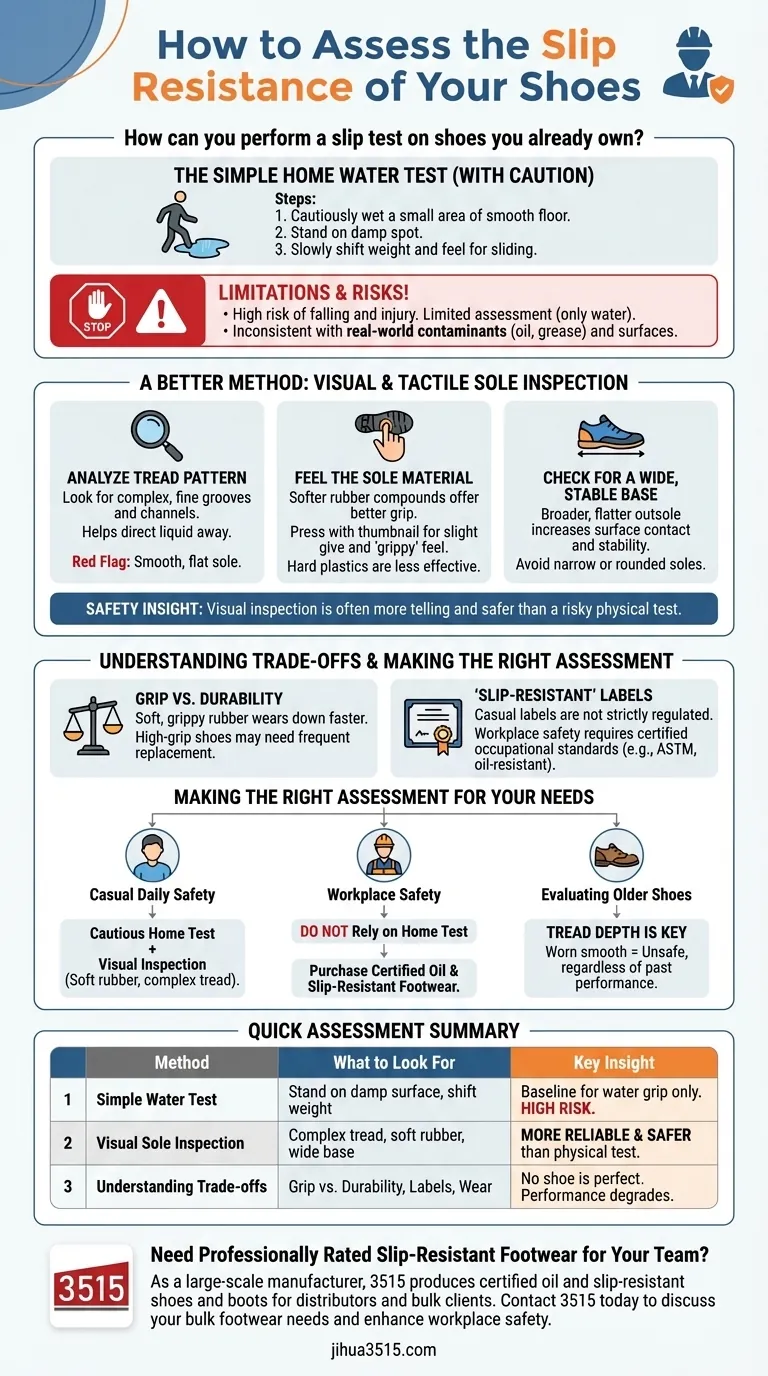

Testing the slip resistance of your shoes at home is a quick way to get a general sense of their grip. To do this, cautiously wet a small area of a smooth, non-porous floor, like tile or vinyl. Stand on the damp spot and slowly shift your weight from one foot to the other, feeling for any sliding or instability. If the soles hold firm without movement, they likely have decent grip on water.

While a simple home test can provide a baseline understanding, it's a very limited assessment. A visual inspection of the shoe's sole and understanding its design provides a far more reliable and safer indicator of its true slip-resistant capabilities.

The Limits of a Home Slip Test

A quick test on your kitchen floor can be informative, but it's crucial to understand its limitations before you rely on the results. Real-world slips happen under conditions that are difficult to replicate safely at home.

Inconsistent Surfaces and Conditions

The tile in your home is different from the polished concrete at a store or the greasy floor of a commercial kitchen. A shoe that holds on one surface may fail on another.

The Danger of Different Contaminants

The most dangerous slips often involve substances like oil, grease, or soap, not just water. A shoe's performance can change dramatically when these elements are introduced, something you should not test at home.

The Risk of the Test Itself

The most obvious flaw is the inherent risk. Attempting to make your shoe slip to test its resistance can easily lead to an actual fall and injury. Caution is paramount.

A Better Method: How to Inspect the Sole

A visual and tactile inspection of your shoe's outsole (the part that contacts the ground) is often more telling than a risky physical test. Know what to look for.

Analyze the Tread Pattern

Effective slip-resistant shoes have complex tread patterns with many fine grooves and channels. These are designed to direct water and other liquids away from the bottom of the shoe, allowing the sole to make direct contact with the ground. A flat, smooth sole is a significant red flag.

Feel the Sole Material

The material of the sole is critical. Softer rubber compounds tend to offer better grip than hard, rigid plastics. Gently press your thumbnail into the sole; if it has a slight give and feels "grippy" to the touch, it's more likely to provide good traction.

Check for a Wide, Stable Base

A wider, flatter outsole provides a larger surface area to contact the floor, which increases stability. Shoes with a broad, stable base are generally safer than those with narrow or rounded soles.

Understanding the Trade-offs

No shoe design is perfect for every situation. Understanding the inherent compromises in slip-resistant footwear helps you make a more informed judgment.

Grip vs. Durability

The soft rubber compounds that provide the best traction often wear down more quickly than harder, more durable materials. This means the most effective non-slip shoes may need to be replaced more frequently, especially with heavy use.

"Slip-Resistant" is Not a Universal Standard

For casual footwear, the term "slip-resistant" is not strictly regulated. If your safety at work is the primary concern, you must look for shoes that are explicitly rated for occupational use, often marked as "oil and slip-resistant" or compliant with specific safety standards (e.g., ASTM).

Performance Can Degrade Over Time

Even a high-quality slip-resistant shoe will lose its effectiveness as the tread wears down. If the intricate patterns on the sole have become smooth, the shoe's ability to channel water is gone, and so is its grip.

Making the Right Assessment for Your Needs

Use your knowledge to evaluate your shoes based on how you intend to use them.

- If your primary focus is casual daily safety: A cautious home water test combined with a visual inspection for soft rubber and complex tread is a reasonable assessment for walking on rainy sidewalks.

- If your primary focus is workplace safety: Do not rely on a home test. Purchase footwear specifically rated for oil and slip resistance that meets certified occupational standards.

- If your primary focus is evaluating older shoes: The most important factor is tread depth. If the sole is worn smooth, it is no longer safe on wet surfaces, regardless of how well it performed when new.

By combining a cautious physical check with a knowledgeable visual inspection, you can make a much more reliable judgment about your footwear's ability to keep you safe.

Summary Table:

| Assessment Method | What to Look For | Key Insight |

|---|---|---|

| Simple Water Test | Stand on a damp, smooth surface and shift weight. | Provides a baseline for water grip only. High risk of falling. |

| Visual Sole Inspection | Complex tread patterns, soft rubber material, wide base. | More reliable and safer than a physical test. |

| Understanding Trade-offs | Grip vs. durability, 'slip-resistant' labels, tread wear. | No shoe is perfect for all conditions; performance degrades over time. |

Need Professionally Rated Slip-Resistant Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of occupational footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified oil and slip-resistant shoes and boots designed to meet strict safety standards, ensuring your workforce is protected from hazardous conditions.

Contact 3515 today to discuss your bulk footwear needs and enhance workplace safety.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection