When you are unsure about a shoe's slip resistance, your best first step is to consult a professional shoe retailer. An expert can assess the sole's material and tread based on experience and advise you on its suitability for specific slippery environments, such as those with grease or water.

Relying on looks alone is a gamble with your safety. True confidence in a shoe's grip comes from either expert assessment or a careful, comparative physical test on a relevant surface.

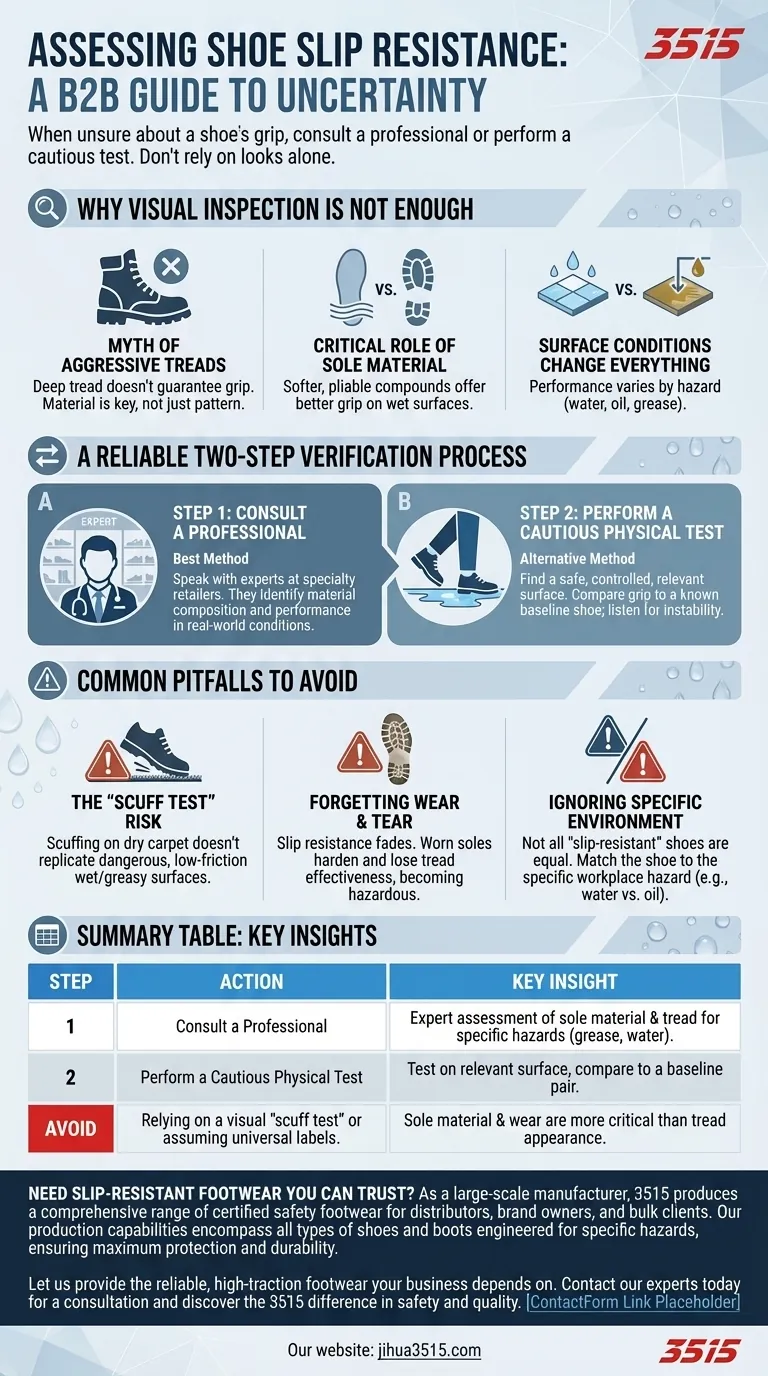

Why Visual Inspection Is Not Enough

Many people believe they can judge a shoe's grip by its appearance. However, the most important factors determining slip resistance are often invisible to the untrained eye.

The Myth of Aggressive Treads

A deep, rugged tread pattern does not automatically guarantee good slip resistance. While tread helps channel water away, the actual grip comes from the material itself.

The Critical Role of Sole Material

The specific rubber or synthetic compound used for the outsole is the single most important factor. Softer, more pliable materials tend to offer better grip on smooth, wet surfaces than hard, rigid ones.

How Surface Conditions Change Everything

A shoe that performs well on a wet tile floor may be dangerously slick on an oily or greasy surface. The specific hazard in your environment dictates what kind of sole you truly need.

A Reliable Two-Step Verification Process

To properly assess a shoe's safety, you need to go beyond a simple glance. Follow this methodical approach to get a clear and reliable answer.

Step 1: Consult a Professional

The most reliable method is to speak with an expert at a specialty shoe store, particularly one that services professional industries. They have seen which brands and materials hold up in real-world conditions.

These professionals can identify the sole's composition and explain how it is engineered to perform on specific surfaces, providing context that a product tag cannot.

Step 2: Perform a Cautious Physical Test

If you cannot consult an expert, you can perform a careful test. Find a controlled, safe area with a surface similar to your work environment, such as a polished or wet tile floor.

First, wear a pair of shoes you know has good (or bad) traction to establish a baseline. Then, switch to the shoes you are testing and cautiously shift your weight, paying close attention to any slipping or instability. A secure grip should feel immediate and firm.

Common Pitfalls to Avoid

Making an assumption about your footwear can lead to a false sense of security, which is often more dangerous than knowing your shoes are inadequate.

The Risk of a Quick "Scuff Test"

Simply scuffing the sole on a dry carpeted floor in a store tells you very little. This action doesn't replicate the dangerous, low-friction conditions of a wet or greasy hard surface.

Forgetting About Wear and Tear

Slip resistance is not permanent. As a shoe's sole wears down, its material hardens and the tread becomes less effective, significantly reducing its grip. An old, worn-out work shoe is a safety hazard.

Ignoring Your Specific Environment

Never assume a shoe labeled "slip-resistant" is appropriate for all conditions. Resistance to water is very different from resistance to oil. Always match the shoe's capability to your specific workplace hazard.

How to Apply This to Your Goal

Your final decision should be guided by the level of risk you face.

- If your primary focus is maximum safety in a hazardous workplace: Always prioritize professional consultation and purchase footwear certified for your specific environmental risks (e.g., oil and slip resistance).

- If your primary focus is evaluating an existing pair of shoes for general use: Perform a cautious comparative test on a wet surface, and if you feel any instability, it is time to replace them.

Ultimately, investing the time to verify your shoe's grip is a direct investment in your personal safety and well-being.

Summary Table:

| Step | Action | Key Insight |

|---|---|---|

| 1 | Consult a Professional | An expert can assess the sole's material and tread for your specific environment (e.g., grease, water). |

| 2 | Perform a Cautious Physical Test | Test the shoe on a similar, safe surface and compare the grip to a baseline pair. |

| Avoid | Relying on a visual 'scuff test' or assuming 'slip-resistant' labels are universal. | Sole material and wear & tear are more critical than tread appearance. |

Need Slip-Resistant Footwear You Can Trust?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots engineered for specific hazards, ensuring maximum protection and durability for your workforce.

Let us provide the reliable, high-traction footwear your business depends on. Contact our experts today for a consultation and discover the 3515 difference in safety and quality.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments