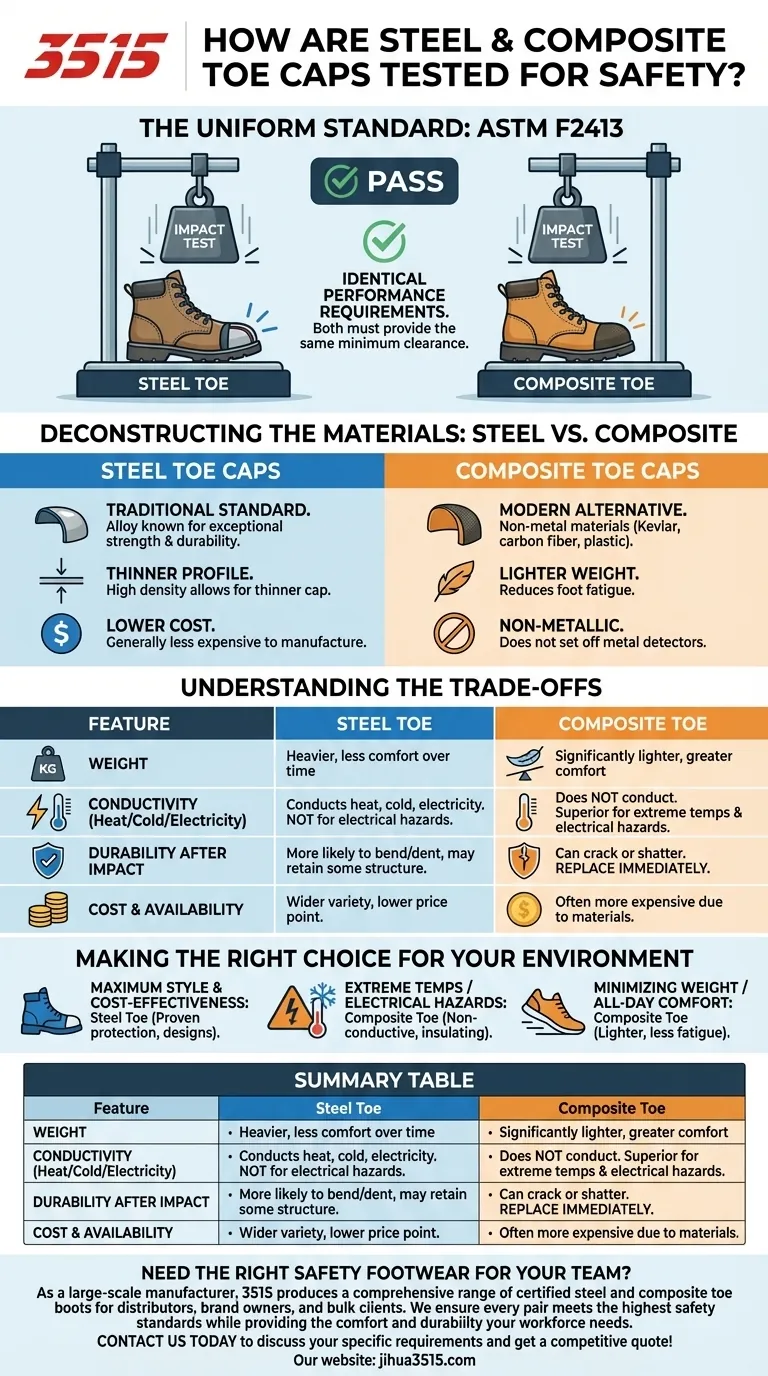

The short answer is this: Steel and composite toe caps are tested for safety using the exact same method. To be certified, both must meet the identical performance requirements for impact and compression resistance as defined by the ASTM F2413 standard.

The question isn't which toe cap passes a better safety test, because the test is identical for both. The real decision hinges on understanding the secondary characteristics of each material—like weight, conductivity, and cost—and matching them to your specific work environment.

The Uniform Standard: ASTM F2413

At the core of safety footwear certification is a single, unified standard. This ensures that no matter the material, the minimum level of protection is consistent and reliable.

Impact and Compression Ratings

The ASTM F2413 standard subjects toe caps to two primary tests. The first is an impact test, which measures the toe cap's ability to protect the foot from a heavy falling object.

The second is a compression test, which measures its ability to withstand a heavy rolling object. To pass, both steel and composite versions must provide the same minimum clearance inside the boot after each test.

What Certification Means for You

This uniform testing means that a certified composite toe boot offers the same fundamental level of protection from impact and compression as a certified steel toe boot. One is not inherently "safer" than the other in a pass/fail scenario. The difference lies in their material properties.

Deconstructing the Materials: Steel vs. Composite

While they meet the same safety benchmark, the materials themselves have very different properties. These differences are what should guide your decision.

Steel Toe Caps: The Traditional Standard

Steel is the original material for safety toes. It is an alloy known for its exceptional strength and durability.

Because of its high density, it can be formed into a thinner cap, sometimes resulting in a less bulky boot profile. It is also generally less expensive to manufacture.

Composite Toe Caps: The Modern Alternative

Composite toe caps are made from non-metal materials like Kevlar, carbon fiber, fiberglass, or plastic.

Their primary advantage is their lighter weight, which can reduce foot fatigue over a long day. They are also completely non-metallic.

Understanding the Trade-offs

Choosing between steel and composite is a matter of balancing their inherent advantages and disadvantages against the demands of your job.

Weight and Comfort

Composite materials are significantly lighter than steel. This reduction in weight can lead to greater comfort and less fatigue, especially during long shifts that involve a lot of walking or climbing.

Conductivity and Environment

This is a critical distinction. Steel conducts heat, cold, and electricity. In extreme temperatures, a steel toe can become uncomfortably hot or cold. Crucially, it is not suitable for environments with certain electrical hazards.

Composite materials do not conduct heat, cold, or electricity. This makes them the superior choice for workers who need insulation from extreme temperatures or operate near live electrical circuits.

Durability After Impact

While both must pass the initial certification tests, their behavior after a significant impact can differ. Steel is more likely to bend or dent but may retain some structural integrity.

Composite materials can crack or shatter upon a severe impact. For this reason, any composite toe boot should be replaced immediately after a significant incident, as its protective capability may be compromised.

Cost and Availability

Steel toe boots have been the industry standard for decades. This has led to a wider variety of styles and, generally, a lower price point.

Composite toe boots are often more expensive due to the higher cost of the materials and manufacturing process.

Making the Right Choice for Your Environment

Your specific workplace hazards and daily tasks should be the ultimate guide for your decision.

- If your primary focus is cost-effectiveness and maximum style options: Steel toe boots offer proven protection at a lower price point and in a wider variety of designs.

- If you work in extreme temperatures or near electrical hazards: Composite toe boots are the definitive choice for their non-conductive, insulating properties.

- If your primary focus is minimizing weight to reduce foot fatigue: The lighter composite toe cap will provide a noticeable advantage in all-day comfort.

Ultimately, choosing the right safety boot comes from a clear understanding of your own protection and comfort needs.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Primary Safety Standard | ASTM F2413 (Identical) | ASTM F2413 (Identical) |

| Key Material Property | Durable, Cost-Effective | Lightweight, Non-Conductive |

| Best For | General use, Cost-conscious buyers | Electrical hazards, Extreme temperatures, All-day comfort |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified steel and composite toe boots for distributors, brand owners, and bulk clients. We ensure every pair meets the highest safety standards while providing the comfort and durability your workforce needs.

Contact us today to discuss your specific requirements and get a competitive quote!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- Do steel toes perform as well as composite toes in extreme weather? A Guide to Thermal Regulation

- What are the main materials used in steel toe safety shoes? A Guide to Protective Footwear Construction

- What are the recommended uses for steel toe safety shoes? Essential Protection for High-Risk Industries

- What are the two safety standards for steel cap boots in Australia and New Zealand? Choose the Right Protection

- When should steel toe boots not be used? Avoid Electrical Hazards and Choose the Right PPE

- What are the primary purposes of steel toe shoes? Essential Foot Protection for Hazardous Workplaces

- Is it true that steel toe boots make your toes colder? The Truth About Cold-Weather Work Boots

- What industries require steel-toe boots? Protect Your Workforce from Common Hazards