In short, industries that require steel-toe safety boots are those where workers face a significant risk of foot injury from falling objects, heavy rolling equipment, or sharp materials. The most common sectors include construction, manufacturing, logging, logistics, and any work involving heavy machinery.

The need for a steel-toe boot is not determined by the industry itself, but by the specific hazards present in the work environment. The core principle is simple: match the level of protection to the level of risk.

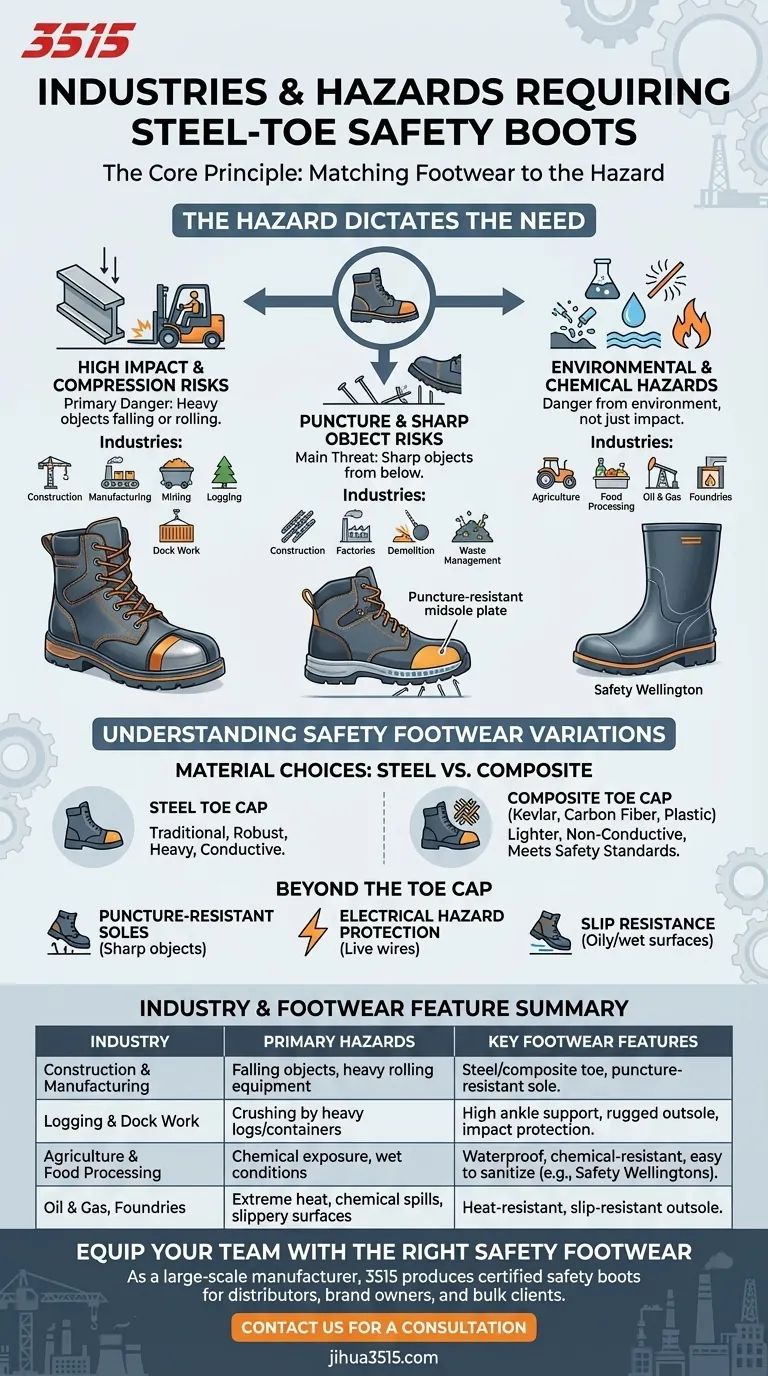

The Core Principle: Matching Footwear to the Hazard

A safety boot requirement is a direct response to predictable workplace dangers. While many industries share common risks, understanding the specific type of hazard is key to understanding why these boots are essential.

Industries with High Impact and Compression Risks

This is the classic scenario for steel-toe boots. The primary danger comes from something heavy falling on or rolling over the foot.

Sectors like construction, manufacturing, and mining are prime examples. Workers are constantly exposed to falling tools, building materials, and heavy equipment like forklifts or mining carts.

Logging and dock work also fall into this category. The immense weight of logs or shipping containers means that any foot injury could be catastrophic, making impact and compression protection non-negotiable.

Industries with Puncture and Sharp Object Risks

In these environments, the main threat comes from below. Workers risk stepping on sharp objects that could pierce a standard boot sole.

While common in construction (nails, rebar) and factories (metal shavings), this risk is also prevalent in demolition, waste management, and ditch digging.

Many safety boots designed for these risks include a puncture-resistant plate in the midsole in addition to the protective toe cap.

Industries with Environmental and Chemical Hazards

Sometimes, the danger isn't from impact but from the environment itself. This is where specialized safety footwear, like Safety Wellingtons, becomes critical.

Agriculture and food processing require boots that are waterproof, easy to sanitize, and resistant to organic materials.

In the oil and gas industry or on foundry floors, workers need protection from chemical spills, extreme heat, and slippery surfaces, all features integrated into specialized safety footwear.

Understanding the Trade-offs and Variations

The term "steel-toe" is often used as a catch-all, but modern safety footwear is more nuanced. Understanding these differences is crucial for selecting the right protection.

Material Choices: Steel vs. Composite

While steel is the traditional material, many modern safety boots use composite toe caps made from materials like Kevlar, carbon fiber, or plastic.

Composite toes are lighter, do not conduct cold or electricity, and still meet the same safety standards for impact and compression. This makes them a better choice for certain environments.

Beyond the Toe Cap: Other Protective Features

True foot protection involves more than just the toe. Many jobs require additional safety features built into the footwear.

These can include puncture-resistant soles, protection against electrical hazards, and outsoles designed for slip resistance on oily or wet surfaces.

The Importance of Fit and Terrain

A boot's design also matters. Loggers, for example, often prefer taller boots for shin protection and an elevated heel for better stability on uneven forest floors.

An uncomfortable or improperly fitted boot can create its own safety hazards by causing fatigue, blisters, or distractions, undermining its protective purpose.

Making the Right Choice for Your Goal

Selecting the right boot means looking past the industry label and focusing on the specific tasks and hazards you will face.

- If your primary focus is heavy industry (Construction, Manufacturing, Mining): Your non-negotiable feature is a certified steel or composite toe cap for impact and compression resistance.

- If your primary focus is a wet or hazardous environment (Agriculture, Food Processing): Prioritize waterproof, chemical-resistant, and easily sanitized footwear, such as Safety Wellingtons.

- If your primary focus involves specialized tasks (Logging, Welding): You must look for features beyond the toe cap, such as puncture-resistant soles, enhanced ankle support, or heat-resistant materials.

Ultimately, the goal of safety footwear is to proactively eliminate a known risk, ensuring you can focus on the job at hand.

Summary Table:

| Industry | Primary Hazards | Key Footwear Features |

|---|---|---|

| Construction & Manufacturing | Falling objects, heavy rolling equipment | Steel/composite toe cap, puncture-resistant sole |

| Logging & Dock Work | Crushing by heavy logs/containers | High ankle support, rugged outsole, impact protection |

| Agriculture & Food Processing | Chemical exposure, wet conditions | Waterproof, chemical-resistant, easy to sanitize (e.g., Safety Wellingtons) |

| Oil & Gas, Foundries | Extreme heat, chemical spills, slippery surfaces | Heat-resistant materials, slip-resistant outsole |

Equip your team with the right safety footwear for their specific hazards.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and footwear for distributors, brand owners, and bulk clients. Whether your team needs classic steel-toe boots for construction, chemical-resistant footwear for processing plants, or specialized logging boots, our production capabilities encompass all types of safety shoes and boots designed to meet rigorous standards.

Contact us today for a consultation to find the perfect protective footwear solution for your industry's unique challenges.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do aluminum safety toes compare to steel toes? A Guide to Lighter, Safer Footwear

- How can calluses be prevented when wearing steel toe boots? A Guide to Lasting Foot Comfort

- What are the primary purposes of steel toe shoes? Essential Foot Protection for Hazardous Workplaces

- Does allowing employees to wear steel-toe rubber boots offsite exempt the employer from payment? Understand OSHA's specialty PPE rules.

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- How do steel toe and composite toe boots differ in thermal insulation? Composite Toes Are Superior Insulators

- What are the advantages of steel toe shoes? Unmatched Protection for Industrial Work

- Why is it important to check the labels on steel cap work boots? Ensure Genuine, Certified Foot Protection