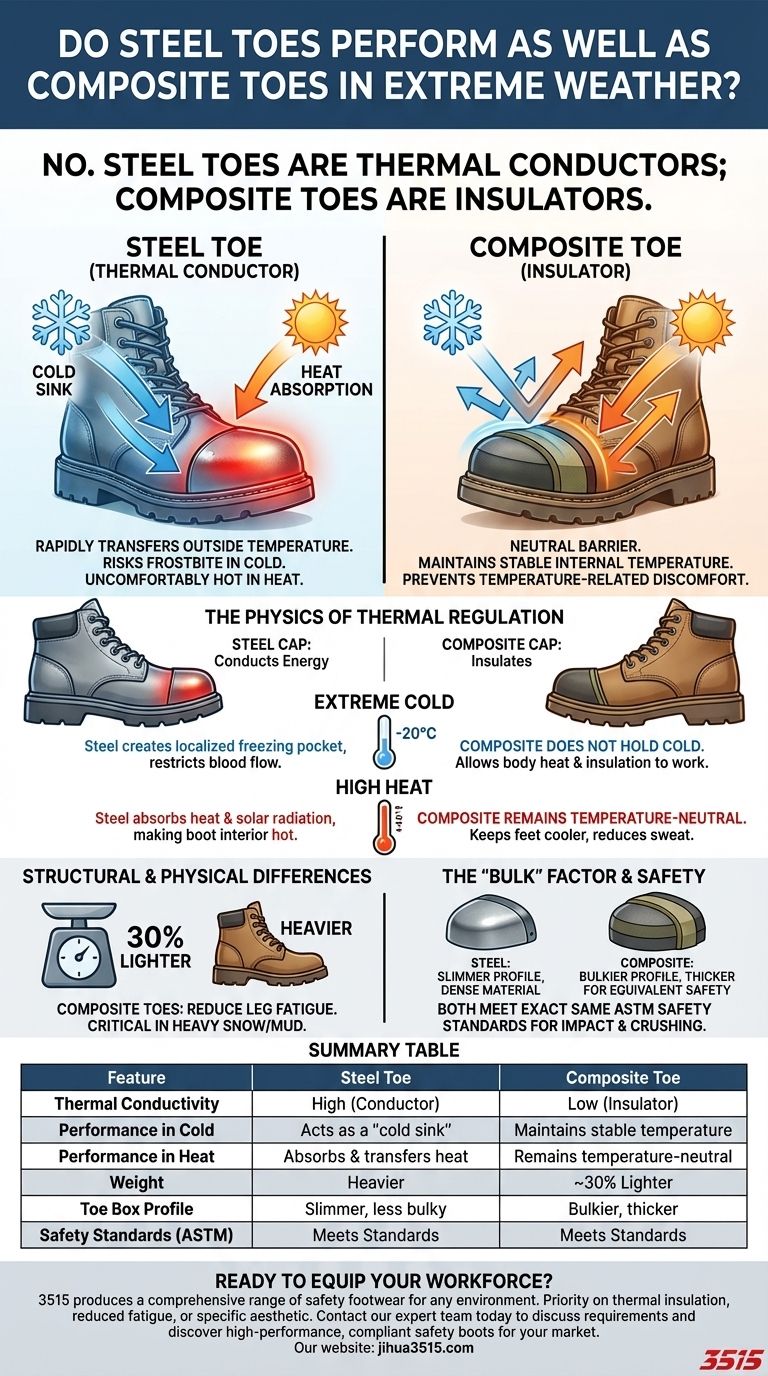

No, steel toes do not perform as well as composite toes in extreme weather conditions. While both materials meet the same impact safety standards, steel acts as a thermal conductor, rapidly transferring outside temperatures to your feet. Conversely, composite toes function as insulators, offering significantly superior thermal regulation in both freezing cold and blistering heat.

Core Takeaway: The "performance" of a safety toe is not just about impact resistance; it is about environmental adaptation. Steel toes act as a thermal bridge that can freeze or scorch your toes, while composite materials provide a neutral barrier that maintains a stable internal boot temperature.

The Physics of Thermal Regulation

Understanding Conductivity

The primary difference between the two materials is thermal conductivity.

Steel is a metal, meaning it naturally absorbs and transfers energy. In a work boot, the steel cap effectively pulls the outside temperature into the toe box, bypassing the boot's leather or synthetic insulation.

Performance in Extreme Cold

In sub-zero environments, a steel toe cap acts as a "cold sink."

It creates a localized pocket of freezing air directly against your toes, which restricts blood flow and increases the risk of frostbite. Composite materials do not hold the cold, allowing your body heat and the boot’s insulation to work efficiently without fighting against a freezing metal plate.

Performance in High Heat

The same principle applies to hot environments, such as asphalt paving or desert field work.

Steel absorbs ambient heat and solar radiation, potentially making the inside of the boot uncomfortably hot. Composite toes remain temperature-neutral, keeping your feet cooler and reducing sweat accumulation.

Structural and Physical Differences

Equivalent Safety Standards

Do not confuse thermal performance with safety capability.

Despite the difference in materials, composite toes meet the exact same ASTM safety ratings as steel toes. They provide equivalent protection against crushing and impact injuries, ensuring your compliance with job site safety regulations.

The Weight Advantage

Composite safety toes are approximately 30% lighter than their steel counterparts.

In extreme weather conditions—such as trudging through heavy snow or thick mud—this weight reduction is critical. A lighter boot reduces leg fatigue, allowing for greater agility and endurance over a long shift.

Understanding the Trade-offs

The "Bulk" Factor

While composite toes are excellent insulators, the material itself is generally not as dense or strong as steel pound-for-pound.

To achieve the same safety rating as steel, composite caps must be physically thicker. This often results in a "bulbous" or bulkier toe profile, which may not appeal to workers who prefer a streamlined look or need to fit their feet into tight mechanical spaces.

Material Options

Not all non-metallic toes are created equal.

Some manufacturers use standard plastics, which contribute to the bulk issue mentioned above. However, advanced options like carbon fiber allow for a thinner profile that rivals steel while maintaining the thermal benefits of a composite.

Making the Right Choice for Your Environment

To select the correct equipment, you must prioritize your environmental constraints over tradition.

- If your primary focus is extreme cold or heat: Choose composite toes. They act as an insulator to keep your feet warm in winter and cool in summer, preventing temperature-related discomfort.

- If your primary focus is reducing fatigue: Choose composite toes. The 30% weight reduction makes a significant difference during long shifts in difficult terrain.

- If your primary focus is a slim profile: Choose steel or alloy toes. If you do not work in extreme temperatures, steel offers a thinner wall and a less bulky silhouette.

Your safety gear should protect you from the elements, not expose you to them.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Thermal Conductivity | High (Conductor) | Low (Insulator) |

| Performance in Cold | Acts as a "cold sink" | Maintains stable temperature |

| Performance in Heat | Absorbs and transfers heat | Remains temperature-neutral |

| Weight | Heavier | ~30% Lighter |

| Toe Box Profile | Slimmer, less bulky | Bulkier, thicker |

| Safety Standards (ASTM) | Meets Standards | Meets Standards |

Ready to equip your workforce with the right safety boots for any environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether your priority is superior thermal insulation for extreme weather, reduced fatigue from lighter materials, or a specific aesthetic profile, we have the production capabilities to meet your needs.

Contact our expert team today to discuss your requirements and discover how we can deliver high-performance, compliant safety boots for your market.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What are the common safety toe types available in work shoes? Steel, Composite & Alloy Explained

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- What are the advantages of wearing steel toe shoes? Maximum Protection for Your Workforce

- What are the key features of steel toe footwear? Maximum Impact Protection for Demanding Work

- How do steel toe boots compare to composite toe boots? Choose the Right Toe for Your Job

- How much weight can steel toe work boots withstand? Unpacking the 3,372 lb. Safety Standard

- What is the purpose of men's safety toe work boots? Complete Foot Protection for Hazardous Work

- What are the advantages of alloy toe work shoes? Lighter Weight, Superior Comfort