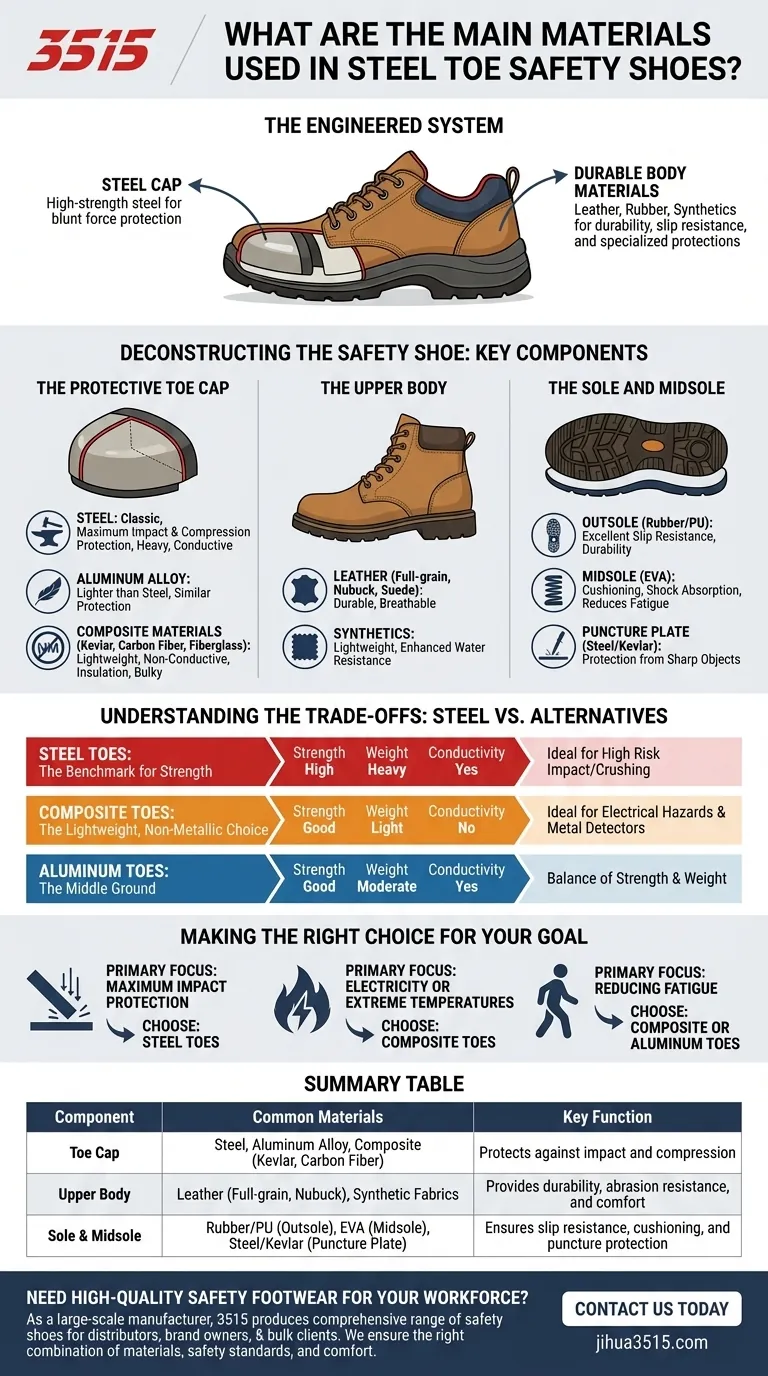

At its core, a steel toe safety shoe is constructed from two primary material groups: a high-strength steel cap for protection and a combination of durable materials like leather, rubber, and synthetics for the shoe's body. The specific materials are chosen to meet demanding safety standards for impact, compression, and traction.

The critical insight is that a safety shoe is an engineered system. The steel toe provides blunt force protection, while the materials of the upper and sole are chosen to provide durability, slip resistance, and specialized protections like electrical hazard resistance.

Deconstructing the Safety Shoe: Key Components

A safety shoe's effectiveness comes from the specific materials used in each of its critical parts. Each component serves a distinct protective function.

The Protective Toe Cap

The defining feature of a steel toe shoe is its reinforced toe cap, designed to protect the foot from falling objects and compression. While steel is the traditional standard, modern options exist.

- Steel: This is the classic material, offering maximum protection against impact and compression. It's exceptionally strong and durable.

- Aluminum Alloy: A lighter alternative to steel, aluminum toes provide similar protection levels but reduce the overall weight of the shoe.

- Composite Materials: These non-metallic options are made from materials like Kevlar, carbon fiber, and fiberglass. They are significantly lighter than steel and do not conduct electricity or temperature.

The Upper Body

The upper part of the shoe must withstand abrasion, chemicals, and daily wear while providing a level of comfort.

- Leather: Full-grain, nubuck, and suede leather are common for their exceptional durability and breathability.

- Synthetics: Modern synthetic fabrics are also used to offer lighter weight and enhanced water resistance.

The Sole and Midsole

The sole is the foundation of the shoe, responsible for traction, support, and protection from ground-level hazards.

- Outsole: Typically made of rubber or polyurethane (PU) for their excellent slip resistance and durability.

- Midsole: Often made of EVA (ethylene vinyl acetate) to provide cushioning and absorb shock, reducing foot fatigue.

- Puncture Plate: For protection against sharp objects from below, a protective plate made of steel or a flexible woven material like Kevlar is often inserted between the midsole and outsole.

Understanding the Trade-offs: Steel vs. Alternatives

Choosing the right toe cap material involves balancing protection, weight, and environmental factors. There is no single "best" material; the right choice depends on the job.

Steel Toes: The Benchmark for Strength

Steel remains the industry standard for jobs with a high risk of severe impact or crushing from heavy objects. Its primary advantage is its immense strength. However, it is the heaviest option and will conduct heat, cold, and electricity if not properly insulated.

Composite Toes: The Lightweight, Non-Metallic Choice

Composite toes are ideal for workplaces with electrical hazards or where employees must pass through metal detectors. Their lightweight nature significantly reduces foot fatigue over a long shift. The main trade-off is that they can be slightly bulkier than steel to achieve the same safety rating.

Aluminum Toes: The Middle Ground

Aluminum offers a balance between the two. It provides the strength of a metal toe cap but at a much lighter weight than steel. This makes it a popular choice for workers who want robust protection without the fatigue associated with heavier steel toe boots.

Making the Right Choice for Your Goal

Your specific work environment and daily tasks should dictate your choice of material.

- If your primary focus is maximum impact protection: Steel toes offer the highest level of defense against compression from heavy equipment or falling debris.

- If your primary focus is working around electricity or in extreme temperatures: Non-metallic composite toes provide superior insulation and are inherently non-conductive.

- If your primary focus is reducing fatigue from walking or standing all day: Composite or aluminum toes offer significant weight savings over traditional steel.

Understanding these core materials empowers you to select safety footwear that provides the precise protection you need for your environment.

Summary Table:

| Component | Common Materials | Key Function |

|---|---|---|

| Toe Cap | Steel, Aluminum Alloy, Composite (Kevlar, Carbon Fiber) | Protects against impact and compression |

| Upper Body | Leather (Full-grain, Nubuck), Synthetic Fabrics | Provides durability, abrasion resistance, and comfort |

| Sole & Midsole | Rubber/PU (Outsole), EVA (Midsole), Steel/Kevlar (Puncture Plate) | Ensures slip resistance, cushioning, and puncture protection |

Need high-quality safety footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring your team gets the right combination of materials, safety standards, and comfort.

Contact us today to discuss your custom or bulk safety shoe requirements!

Visual Guide

Related Products

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What are the advantages of steel toe work boots? Maximum Protection for Heavy-Duty Work

- What are some misconceptions about the weight differences between safety toe materials? The Truth About Heavy Boots

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- What is the purpose of steel toe shoes? Essential Protection for Hazardous Workplaces