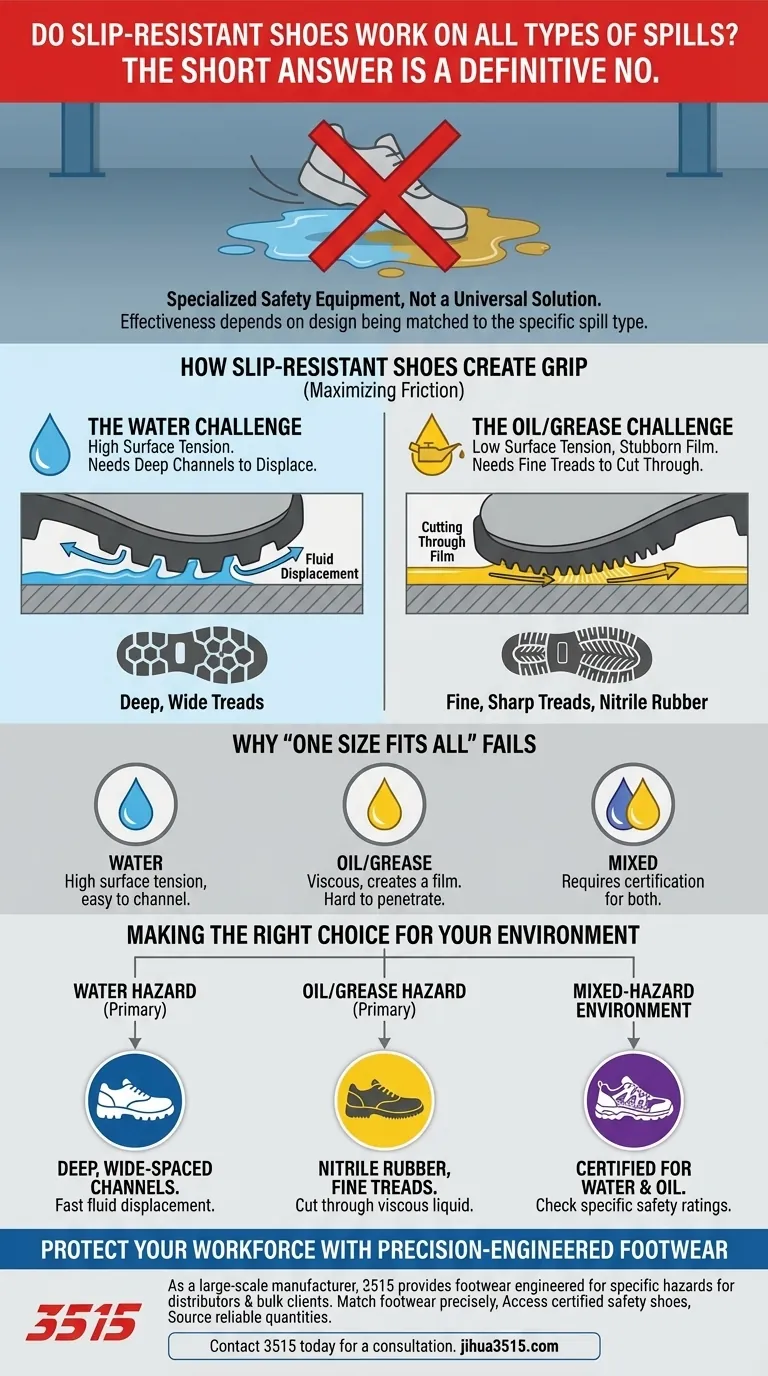

The short answer is a definitive no. Slip-resistant shoes are highly specialized safety equipment, not a universal solution. Their effectiveness is entirely dependent on the shoe's design being matched to the specific type of spill. A shoe engineered to grip on water may fail completely on a greasy or oily surface.

True slip resistance is not a generic feature but a specific design solution. The key is to understand the physics of the hazard you face—whether it's water, oil, or food—and to select a shoe with a sole material and tread pattern engineered specifically for that challenge.

How Slip-Resistant Shoes Create Grip

The Principle of Friction

At their core, slip-resistant shoes work by maximizing friction, which is the force that resists motion when two surfaces rub against each other. The more friction a shoe's sole can generate against the floor, the less likely you are to slip.

The Role of the Sole Material

These shoes are not made from standard polymers. They utilize high-grade, soft synthetic rubber compounds that are designed to provide a stronger grip on slick surfaces compared to the harder soles of typical footwear.

The Importance of Tread Design

The pattern of the grooves, or tread, is not accidental. Intricate patterns, often using hexagonal or circular shapes, are engineered to function like tire treads. They actively channel liquid out and away from the sole of the shoe.

Why Groove Depth Matters

This design ensures that the rubber makes direct contact with the floor surface, rather than hydroplaning on a thin layer of fluid. Deeper grooves are more effective at displacing larger amounts of liquid and increasing the overall friction.

Why "One Size Fits All" Fails

The Water vs. Oil Problem

This is the most critical distinction. Water has high surface tension and is relatively easy for a well-designed tread to channel away.

Oils and greases, however, are more viscous and have lower surface tension. They create a stubborn film that is much harder to break through. Shoes designed for oil need a different rubber compound and tread pattern to effectively "cut" through the spill and make contact with the floor.

Matching the Shoe to the Hazard

A shoe tested and proven effective on water is not guaranteed to work on oil. This is why environments like commercial kitchens, garages, and industrial plants require footwear specifically rated for oil and chemical resistance, not just general wet conditions.

Common Pitfalls to Avoid

Assuming All "Safety Shoes" Are Equal

The term "safety shoe" is broad. It can refer to features like a steel toe or puncture resistance, neither of which guarantees slip resistance. You must look for the specific slip-resistant certification relevant to your environment.

Relying on Temporary Solutions

Aftermarket sprays and disposable shoe covers are not reliable substitutes for properly engineered footwear. They may offer a minor, short-term benefit, but they cannot provide the certified protection needed in a professional setting.

Ignoring Shoe Maintenance and Wear

The effectiveness of a slip-resistant shoe degrades over time. As the tread wears down, its ability to channel away fluid diminishes significantly. A worn-out sole is no longer a safe sole.

Making the Right Choice for Your Environment

To ensure safety, you must match your footwear directly to the most common hazards in your workspace.

- If your primary hazard is water: Look for shoes with deep, wide-spaced channels and tread patterns designed to quickly displace fluid.

- If your primary hazard is oil or grease: Prioritize footwear with nitrile rubber soles and a finer tread pattern that can cut through viscous liquids.

- If you work in a mixed-hazard environment: Choose a shoe explicitly tested and certified for both water and oil-based slips, and check its specific safety ratings.

Choosing the right slip-resistant shoe isn't about finding a single solution; it's about making an informed engineering decision for your safety.

Summary Table:

| Spill Type | Key Challenge | Recommended Shoe Feature |

|---|---|---|

| Water | High surface tension, easy to hydroplane | Deep, wide-spaced treads for fast fluid displacement |

| Oil/Grease | Low surface tension, creates a stubborn film | Nitrile rubber soles with fine treads to cut through the film |

| Mixed Hazards | Combination of water, oil, and other liquids | Shoes explicitly tested and certified for both water and oil resistance |

Protect Your Workforce with Precision-Engineered Footwear

Choosing the wrong slip-resistant shoe can compromise safety and lead to costly workplace accidents. As a large-scale manufacturer, 3515 produces a comprehensive range of footwear engineered for specific hazards. We provide the right solution for distributors, brand owners, and bulk clients, ensuring maximum safety and durability.

We help you:

- Match footwear precisely to your unique environmental hazards (water, oil, grease).

- Access certified safety shoes with the correct sole compounds and tread patterns.

- Source reliable, bulk quantities for your entire team with consistent quality.

Don't gamble with safety—get footwear designed for your specific risks.

Contact 3515 today for a consultation and let our expertise guide you to the safest choice.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What features make safety clogs suitable for hygienic environments? Slip-Resistant, Easy-to-Clean Design

- What is the difference between non-slip and slip-resistant shoes? The Truth About Safety Footwear

- What type of midsoles are used in men's work shoes to prevent foot injuries? Steel vs. Composite for Ultimate Safety

- What is the primary function of integrated physiological monitoring systems? Tracking ANS Health in Professional Shoes

- What should be considered when choosing non-slip shoes for the workplace? Select the Right Safety Footwear

- Why are clogs suitable for healthcare and culinary professionals? Unlock Superior Safety & Comfort

- What should you consider when choosing slip-resistant shoes? Ensure Maximum Safety and Comfort

- What role do specialized anti-slip cleats on the soles of professional footwear play in preventing injuries? Stability