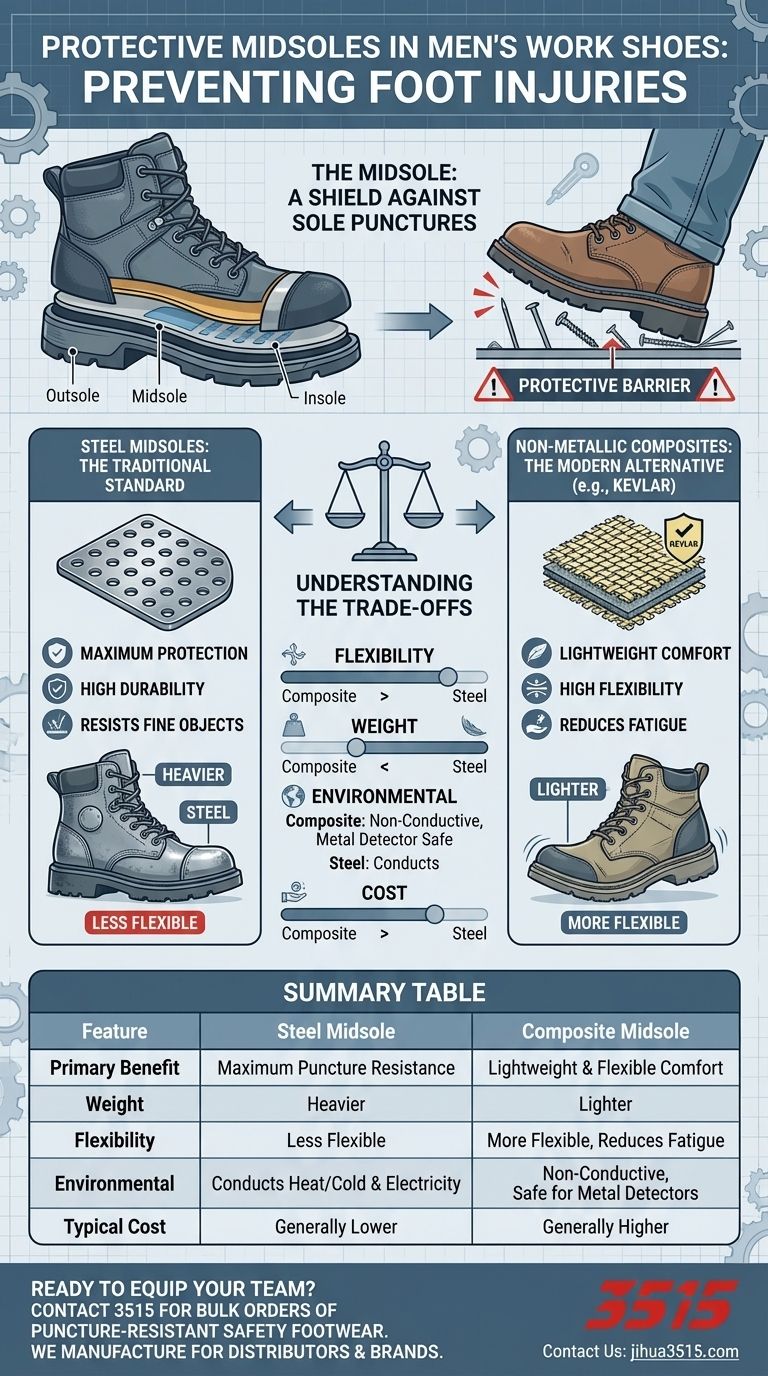

To prevent foot injuries from sole punctures, men's work shoes primarily use two types of protective midsoles: steel and non-metallic composites, such as Kevlar. These specialized midsoles are engineered to act as a shield between your foot and sharp objects on the ground, such as nails, screws, or glass.

The choice of a protective midsole is a critical decision that balances the absolute puncture resistance of steel against the lightweight flexibility and comfort offered by modern composite materials like Kevlar.

The Role of the Midsole in Foot Protection

The midsole is a layer located between the part your foot rests on (the insole or footbed) and the part that touches the ground (the outsole). While many midsoles are designed for shock absorption, protective work shoes add a crucial puncture-resistant plate to this layer.

Beyond Cushioning: The Protective Barrier

In a standard shoe, the midsole provides cushioning and support. In a safety-rated work shoe, a puncture-resistant plate is embedded within this layer to create a physical barrier against hazards.

The Primary Threat: Puncture Wounds

The specific goal of these midsoles is to prevent sharp objects from piercing the sole of the shoe and causing serious injury to the foot. This is a common risk in construction, demolition, and industrial waste environments.

A Breakdown of Puncture-Resistant Materials

The decision between the two main categories of protective midsoles—steel and composite—depends entirely on the demands of your job and your personal comfort priorities.

The Traditional Standard: Steel Midsoles

Steel midsoles are the classic, time-tested solution for puncture protection. They consist of a thin, durable plate of steel engineered to resist penetration.

They are known for being highly durable and offer excellent protection against even the finest sharp objects.

The Modern Alternative: Non-Metallic Composites

Non-metallic midsoles are made from layers of high-strength woven materials, with Kevlar being the most well-known. These fibers are tightly interlaced to stop sharp objects.

This technology provides a lighter and more flexible alternative to steel, bending more easily with the natural movement of your foot.

Understanding the Trade-offs

Neither material is universally "better"; they simply serve different needs. Understanding their core differences is key to choosing the right boot.

Flexibility and Fatigue

Composite midsoles offer significantly more flexibility than steel. This can reduce foot fatigue over a long workday, as the shoe moves more naturally with your stride.

Weight and Comfort

The most noticeable difference is weight. Composite midsoles are substantially lighter than steel, which contributes directly to all-day comfort and reduces the overall strain on your legs.

Environmental Factors

Non-metallic midsoles do not conduct heat, cold, or electricity. This makes them the superior choice for work in extreme temperatures or in environments requiring passage through metal detectors.

Cost Considerations

Generally, work shoes featuring advanced composite midsoles like Kevlar tend to be more expensive than their traditional steel-soled counterparts.

Making the Right Choice for Your Work Environment

Your specific job site and daily tasks should guide your decision.

- If your primary focus is maximum protection in a heavy-duty construction zone: Steel midsoles provide a proven and highly reliable barrier against fine-pointed objects.

- If your primary focus is all-day comfort, flexibility, and reduced fatigue: Non-metallic composite midsoles are the ideal choice, especially if you walk long distances.

- If your primary focus is working in secure areas or extreme temperatures: Non-metallic midsoles are essential, as they will not set off metal detectors or conduct heat and cold.

Ultimately, understanding the material in your midsole is a critical step in building the right foundation for your safety and comfort on the job.

Summary Table:

| Feature | Steel Midsole | Composite Midsole (e.g., Kevlar) |

|---|---|---|

| Primary Benefit | Maximum puncture resistance | Lightweight & flexible comfort |

| Weight | Heavier | Lighter |

| Flexibility | Less flexible | More flexible, reduces fatigue |

| Environmental | Conducts heat/cold & electricity | Non-conductive, safe for metal detectors & extreme temps |

| Typical Cost | Generally lower | Generally higher |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of puncture-resistant work shoes and boots for distributors, brand owners, and bulk clients. Whether your priority is the absolute protection of steel midsoles or the advanced comfort of composite materials like Kevlar, we have the production capabilities and expertise to meet your needs.

Contact 3515 today to discuss your requirements and get a quote for durable, safety-compliant footwear.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- How do slip resistant shoes contribute to productivity at work? Boost Focus & Efficiency with Secure Footing

- Why are slip resistant shoes important in the workplace? Prevent Costly Accidents & Protect Your Team

- What should be considered when choosing non-slip shoes for the workplace? Select the Right Safety Footwear

- What are the characteristics of server shoes that make them non-slip? Essential Features for Maximum Safety

- How can scuffing the outsoles of shoes improve traction? Prevent slips with simple physics.

- How does the comfort of specialized work shoes influence biosecurity compliance? Drive Adherence in Agriculture

- What key features make a shoe slip-resistant? The Essential Guide to Safer Footwear

- How do slip-resistant shoes contribute to comfort and peace of mind? Enhance Safety and Reduce Fatigue