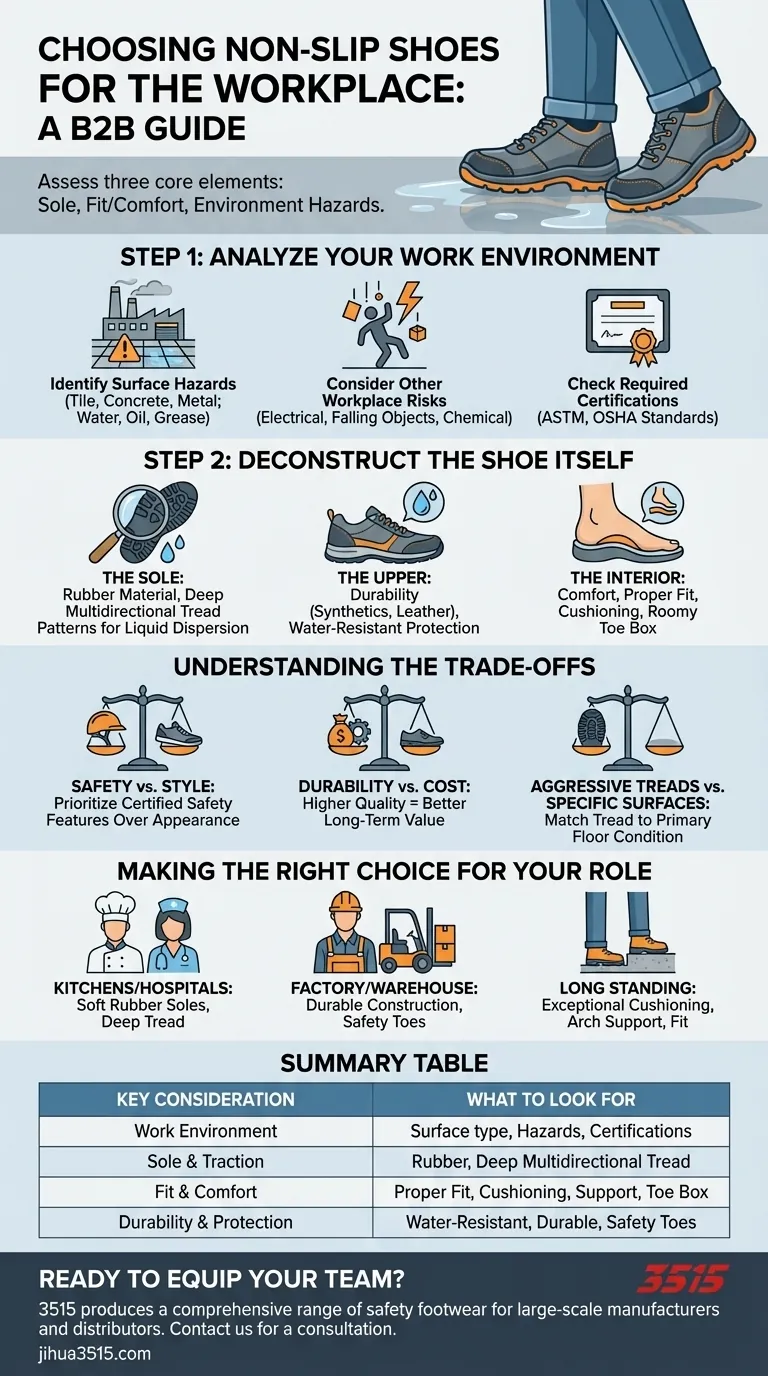

When choosing non-slip shoes for the workplace, you must look beyond the label and assess three core elements: the sole's material and tread pattern for traction, the overall fit and comfort for consistent wear, and the specific hazards of your unique work environment. A shoe that excels in one area may fail completely in another.

The most effective non-slip shoe is not simply the one with the best grip. It is a complete system where the tread design, material, fit, and comfort are correctly matched to the specific surfaces and daily demands of your job.

Step 1: Analyze Your Work Environment

Before looking at any shoe, you must first understand the specific challenges you face daily. The environment dictates the necessary features.

Identify Surface Hazards

The primary factor is the type of floor you walk on. Is it tile, concrete, or metal?

Most importantly, what substances create the slip risk? Water, oil, grease, and cleaning fluids all interact differently with shoe soles.

Consider Other Workplace Risks

Your job may have risks beyond slipping. Consider if you need protection from electrical discharges, falling objects, or chemical splashes.

These additional requirements will narrow your options to shoes that offer composite safety features, not just a non-slip sole.

Check for Required Certifications

Many industries have specific safety regulations (like ASTM or OSHA standards) that footwear must meet.

Consult with your employer or safety manager to ensure the shoes you consider carry the necessary certifications for your sector.

Step 2: Deconstruct the Shoe Itself

Once you understand your environment, you can evaluate a shoe’s specific components to see if they meet the demand.

The Sole: Material and Design

The foundation of a non-slip shoe is its outsole. Rubber is the most effective material for wet and oily surfaces due to its high coefficient of friction.

Look for a tread pattern with deep, multidirectional grooves. These channels are designed to push liquids out from under the shoe, allowing the sole to make direct contact with the floor.

The Upper: Durability and Protection

The upper part of the shoe must be durable enough for your job's demands. Materials like high-quality synthetics or leather offer longevity and protection.

If you work in wet conditions, a water-resistant upper is critical for keeping your feet dry and preventing discomfort.

The Interior: Comfort and Support

Safety features are useless if the shoe is too uncomfortable to wear correctly. Prioritize a proper fit over style.

Look for features like supportive insoles, adequate cushioning, and a roomy toe box. Your feet can swell throughout a long shift, and a tight fit can cause significant pain and distraction.

Understanding the Trade-offs

No single shoe is perfect for every situation. Choosing the right pair involves balancing competing priorities.

Safety vs. Style

The most common mistake is prioritizing aesthetics. True work shoes are tools designed for a function. Always place certified safety features and a secure fit above appearance.

Durability vs. Initial Cost

A higher-quality shoe with a durable sole and strong construction may have a higher upfront cost but provides better value over time.

Cheaper shoes can wear out quickly, losing their slip-resistant properties and requiring frequent, costly replacement.

Aggressive Treads vs. Specific Surfaces

An extremely aggressive tread designed for liquids might be less effective or even a tripping hazard on dry, smooth surfaces. Match the tread to your primary floor condition.

Making the Right Choice for Your Role

Your specific job function should be the final filter for your decision.

- If your primary focus is working in kitchens or hospitals with frequent spills: Prioritize soft rubber soles with deep, intricate tread patterns that channel liquids away effectively.

- If your primary focus is on a factory or warehouse floor: Look for durable construction and consider additional safety features like a steel or composite toe.

- If your primary focus is standing for long periods on hard surfaces: Emphasize exceptional cushioning, strong arch support, and a comfortable fit to prevent fatigue and long-term injury.

Investing in the right footwear is a direct investment in your daily safety and well-being.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Work Environment | Surface type (tile, concrete), hazards (water, oil), required certifications (ASTM, OSHA). |

| Sole & Traction | Rubber material, deep and multidirectional tread patterns for effective liquid dispersion. |

| Fit & Comfort | Proper fit, cushioning, arch support, and a roomy toe box for all-day wear. |

| Durability & Protection | Water-resistant uppers, durable construction, and additional safety toes if needed. |

Ready to equip your team with the right non-slip footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We understand that the right shoe is a complete system, and our production capabilities encompass all types of non-slip shoes and boots tailored to your specific industry hazards—from kitchens and hospitals to warehouses and factories.

Let us help you enhance workplace safety and comfort. Contact 3515 today for a consultation and discover how our expertise can benefit your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health