Choosing the right slip-resistant shoes involves evaluating three core areas: the specific design of the outsole for grip, the overall construction for durability and support, and a precise fit for all-day comfort and safety. These factors work together to protect you in demanding work environments where falls are a significant risk.

The "slip-resistant" label on a shoe is only the starting point. True safety comes from understanding how a shoe's outsole design—its material, tread pattern, and groove depth—interacts with your specific work environment, while proper fit ensures the shoe remains effective and comfortable throughout your shift.

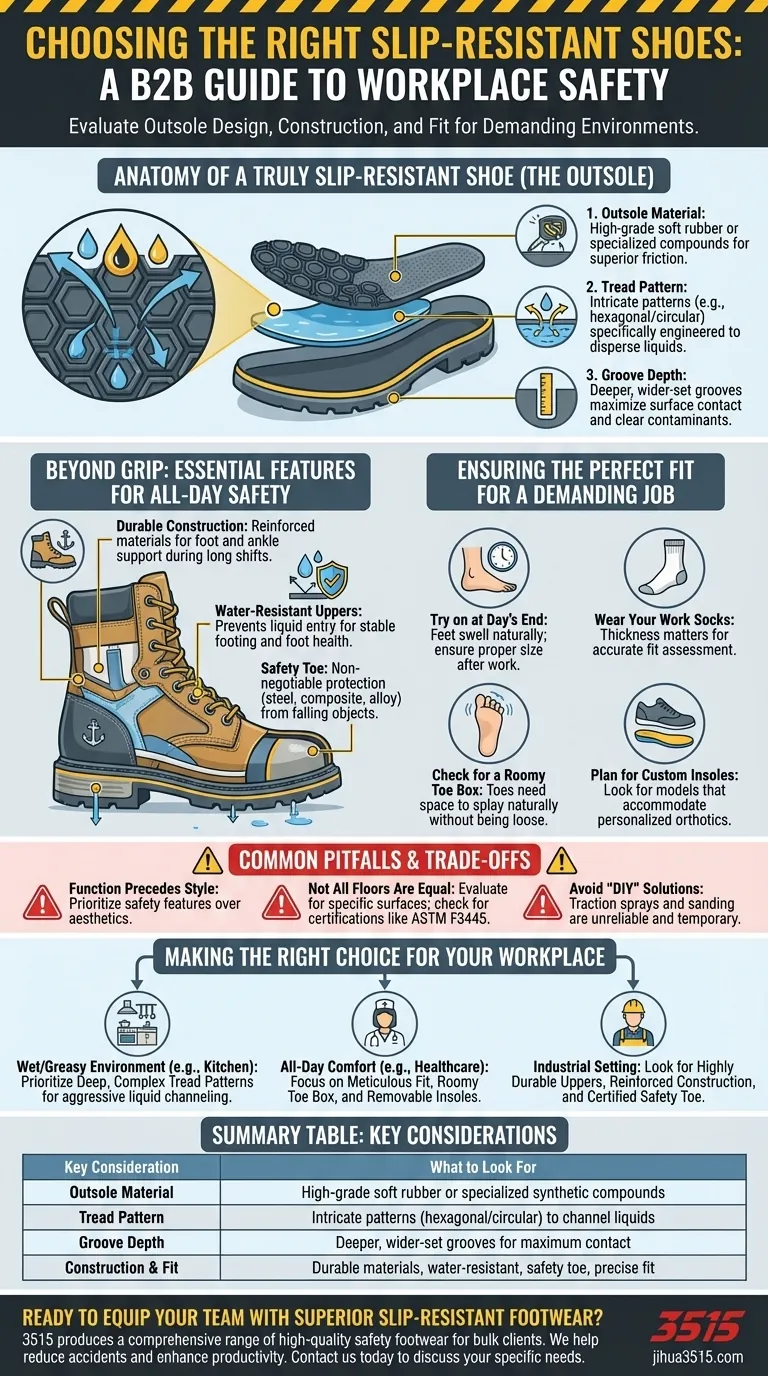

The Anatomy of a Truly Slip-Resistant Shoe

To make an informed decision, you must look beyond marketing claims and understand the specific design elements that provide reliable traction. These features are engineered to combat common workplace hazards like water, oil, and grease.

Outsole Material: The Foundation of Grip

The outsole is the part of the shoe that contacts the floor, and its material is critical. High-grade soft rubber or specialized synthetic compounds are used because they create more friction than the materials found in standard footwear.

Tread Pattern: Channeling Away Hazards

The pattern of the tread is engineered to disperse liquids. Look for intricate patterns, often hexagonal or circular, which act like tire treads on a wet road. They create channels that push fluids out from under the shoe, allowing the sole to make direct contact with the floor.

Groove Depth: Maximizing Surface Contact

The depth of the grooves in the outsole significantly impacts performance. Deeper, wider-set grooves provide more edges to grip the floor surface and are more effective at clearing away contaminants, which is especially important in environments with thick or greasy spills.

Beyond Grip: Essential Features for All-Day Safety

While the outsole is the key to preventing slips, other features determine whether a shoe is truly suitable for a professional setting. Durability, protection, and comfort are just as important for long-term use.

Durable and Supportive Construction

Slip-resistant shoes are built to withstand heavy-duty tasks. They feature reinforced materials and sturdy construction that provide essential foot and ankle support, which is critical for long shifts spent standing or walking.

Water-Resistant Uppers

Keeping your feet dry is not just a matter of comfort. Water-resistant upper materials prevent liquids from seeping into the shoe, which helps maintain a stable footing inside the shoe and supports overall foot health.

The Importance of a Safety Toe

For many industrial, construction, or warehouse environments, toe protection is a non-negotiable safety feature. Whether steel, composite, or alloy, a reinforced toe cap protects you from falling objects and compression injuries.

Understanding the Trade-offs and Common Pitfalls

Choosing the right shoe also means recognizing potential downsides and avoiding common mistakes that can compromise your safety.

Function Must Precede Style

The most effective slip-resistant shoes are built for a specific purpose. This often means their design prioritizes function and safety over aesthetics. Accepting this trade-off is the first step toward finding genuinely protective footwear.

Not All Floors Are Created Equal

A shoe that performs well on a wet, polished floor may not be effective on a greasy kitchen tile. You must evaluate the shoe's suitability for the specific surfaces you encounter daily. Check for certifications like ASTM F3445, which indicates the shoe has passed standardized slip-resistance tests.

Avoid Unreliable "DIY" Solutions

Applying traction sprays, scuffing soles with sandpaper, or using other home remedies are temporary and highly unreliable fixes. They cannot replace the engineered grip of a properly designed slip-resistant outsole and may create a false sense of security.

Ensuring the Perfect Fit for a Demanding Job

An ill-fitting shoe, no matter how well-designed, can cause pain, blisters, and fatigue, ultimately becoming a safety hazard itself.

Try Shoes at the End of the Day

Your feet naturally swell over the course of the day. To ensure a proper fit, always try on new work shoes after your shift or in the late afternoon.

Wear Your Work Socks

The thickness of your socks can significantly alter how a shoe fits. Always wear your typical work socks when trying on shoes to get an accurate sense of the size and width you need.

Check for a Roomy Toe Box

Your toes need space to splay naturally as you walk. Ensure there is enough room in the toe box to wiggle your toes freely without the shoe feeling loose.

Plan for Custom Insoles

If you use custom orthotics for support, look for shoes with removable insoles. This allows you to insert your own for personalized comfort without compromising the shoe's fit.

Making the Right Choice for Your Workplace

Your final decision should be guided by the unique demands of your job.

- If your primary focus is a wet or greasy environment (like a kitchen): Prioritize shoes with deep, complex outsole tread patterns designed to aggressively channel liquids away.

- If your primary focus is all-day comfort during long shifts (like in healthcare): Pay meticulous attention to fit, ensuring a roomy toe box and considering models with removable insoles for custom support.

- If your primary focus is durability in an industrial setting: Look for shoes with highly durable upper materials, reinforced construction, and a certified safety toe.

Investing in the right footwear is a direct investment in your daily safety and well-being.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Outsole Material | High-grade soft rubber or specialized synthetic compounds for superior grip. |

| Tread Pattern | Intricate patterns (hexagonal/circular) to channel away liquids effectively. |

| Groove Depth | Deeper, wider-set grooves for maximum surface contact and contaminant clearance. |

| Construction & Fit | Durable materials, water-resistant uppers, safety toes, and a precise fit for all-day comfort. |

Ready to equip your team with superior slip-resistant footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the precise outsole designs, durable construction, and comfortable fits detailed in this article.

We help you protect your workforce, reduce workplace accidents, and enhance productivity. Contact our experts today to discuss your specific needs and discover how 3515 can be your reliable partner in safety.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security