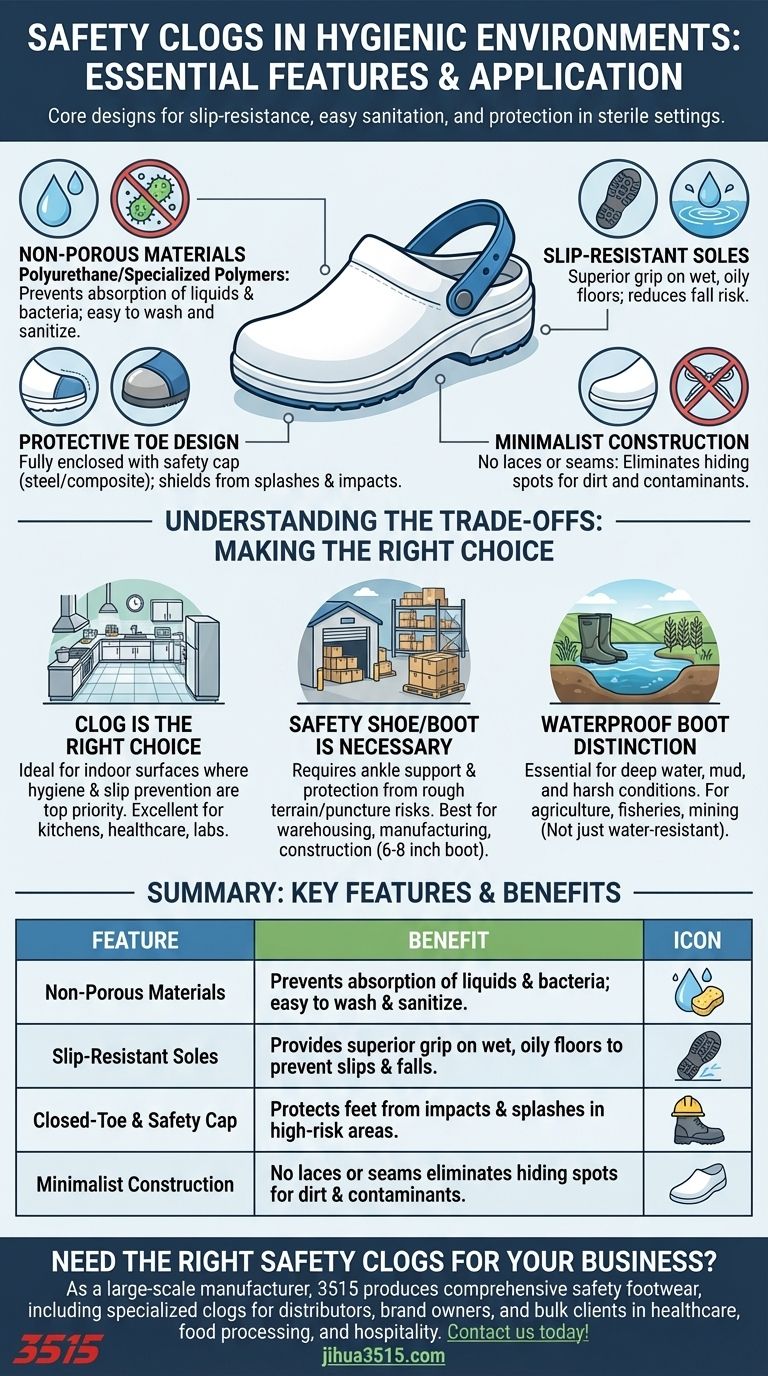

At their core, safety clogs are designed for hygienic environments through a combination of three key features: slip-resistant soles for wet or greasy floors, non-porous and easy-to-sanitize materials like polyurethane, and a closed-toe design that often includes a protective safety cap.

The suitability of a safety clog comes from its minimalist design. By eliminating features like laces and fabric seams where contaminants can hide, it offers a surface that is exceptionally easy to clean and disinfect while still providing essential protection against slips and impacts.

Core Features for Hygienic Safety

To understand why clogs are a mainstay in environments like hospitals, kitchens, and food processing plants, we need to analyze how their specific features address the unique risks of these workplaces.

Non-Porous, Easy-to-Clean Materials

The primary material used in safety clogs, such as polyurethane or specialized polymers, is non-porous.

This is a critical feature because it means the material will not absorb liquids, chemicals, or biological matter. This prevents the growth of bacteria and makes the entire clog simple to wash and sanitize at the end of a shift.

Superior Slip Resistance

Hygienic environments frequently have floors that are wet, oily, or otherwise slick.

Safety clogs feature specially designed slip-resistant outsoles with tread patterns engineered to channel away liquids and maintain a firm grip on smooth surfaces, significantly reducing the risk of falls.

Protective Toe Design

Spills are not the only hazard. Dropped tools, equipment, or sharp objects are common risks.

Clogs provide a fully enclosed toe box to shield the foot from splashes and impacts. Many models are also rated for safety with built-in steel or composite toe caps, offering certified protection against heavy falling objects.

Minimalist Construction

The absence of features is just as important as their presence. Safety clogs lack laces, complex stitching, or fabric panels.

These areas are notorious for trapping dirt, food particles, and microbes, making them difficult to clean. The smooth, seamless design of a clog eliminates these harborages for contaminants.

Understanding the Trade-offs: Clogs vs. Other Footwear

While ideal for their intended purpose, safety clogs are a specialized tool. Choosing the wrong footwear can introduce new risks, so understanding their limitations is crucial.

When a Clog is the Right Choice

Clogs excel on flat, indoor surfaces where hygiene and slip prevention are the top priorities. Their ease of cleaning and comfort for long periods of standing make them the superior choice for kitchens, healthcare facilities, and laboratories.

When a Safety Shoe or Boot is Necessary

Clogs offer minimal ankle support and are not designed for rough terrain or environments with significant puncture risks from below.

Warehousing, manufacturing, or general construction work demands the added support and durability of a 6-inch or 8-inch safety boot, which provides better stability and protection against a wider range of physical hazards.

The Waterproof Boot Distinction

While clogs are water-resistant, they are not designed for submersion or heavy outdoor water exposure.

Professions in agriculture, fisheries, or mining require a dedicated waterproof boot. These are built for deep water, mud, and harsh conditions, a level of protection a clog simply cannot provide.

Making the Right Choice for Your Environment

Your choice must be dictated by a clear assessment of your daily tasks and the primary hazards you face.

- If your primary focus is hygiene and slip resistance on indoor surfaces: The easy-to-sanitize, non-slip design of a safety clog is the ideal solution.

- If your primary focus is general protection in a warehouse or factory: A safety shoe or 6-inch boot provides the necessary impact protection and ankle support.

- If your primary focus is protection from the elements or heavy-duty hazards: An 8-inch or specialized waterproof boot is essential for maximum safety and durability.

Ultimately, selecting the correct safety footwear is a foundational step in managing workplace risk effectively.

Summary Table:

| Feature | Benefit for Hygienic Environments |

|---|---|

| Non-Porous Materials | Prevents absorption of liquids & bacteria; easy to wash and sanitize. |

| Slip-Resistant Soles | Provides superior grip on wet, oily floors to prevent slips and falls. |

| Closed-Toe & Safety Cap | Protects feet from impacts and splashes in high-risk areas. |

| Minimalist Construction | No laces or seams eliminates hiding spots for dirt and contaminants. |

Need the right safety clogs for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear, including specialized clogs perfect for distributors, brand owners, and bulk clients in the healthcare, food processing, and hospitality sectors. Our production capabilities ensure you get high-quality, hygienic footwear designed for durability and safety.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- How do slip-resistant shoes benefit older individuals? Prevent Falls and Enhance Stability

- What are the essential features for restaurant and food service work shoes? Ensure Safety and Comfort for Your Team

- Why are chemical cleaners containing surfactants used in slip-resistant footwear research? Achieve Critical Safety.

- What is the difference between oil resistance and slip resistance in footwear? Protect Your Boots and Your Safety

- What are oil-resistant shoes and boots designed for? Protect Your Footwear from Oil Damage

- What are the main components of a slip-resistant shoe? Unpacking the Anatomy of Workplace Safety

- What is the purpose of standardized anti-slip socks in stability experiments? Unlock Precise Footwear R&D Data

- What is the purpose of a digital surface profilometer in footwear testing? Master Surface Roughness & Slip Resistance