Okay, here's the deal: you're trying to figure out if there's a real difference between "non-slip" and "slip-resistant" shoes, and ultimately, you want to make a safe purchase. Let's get right to it.

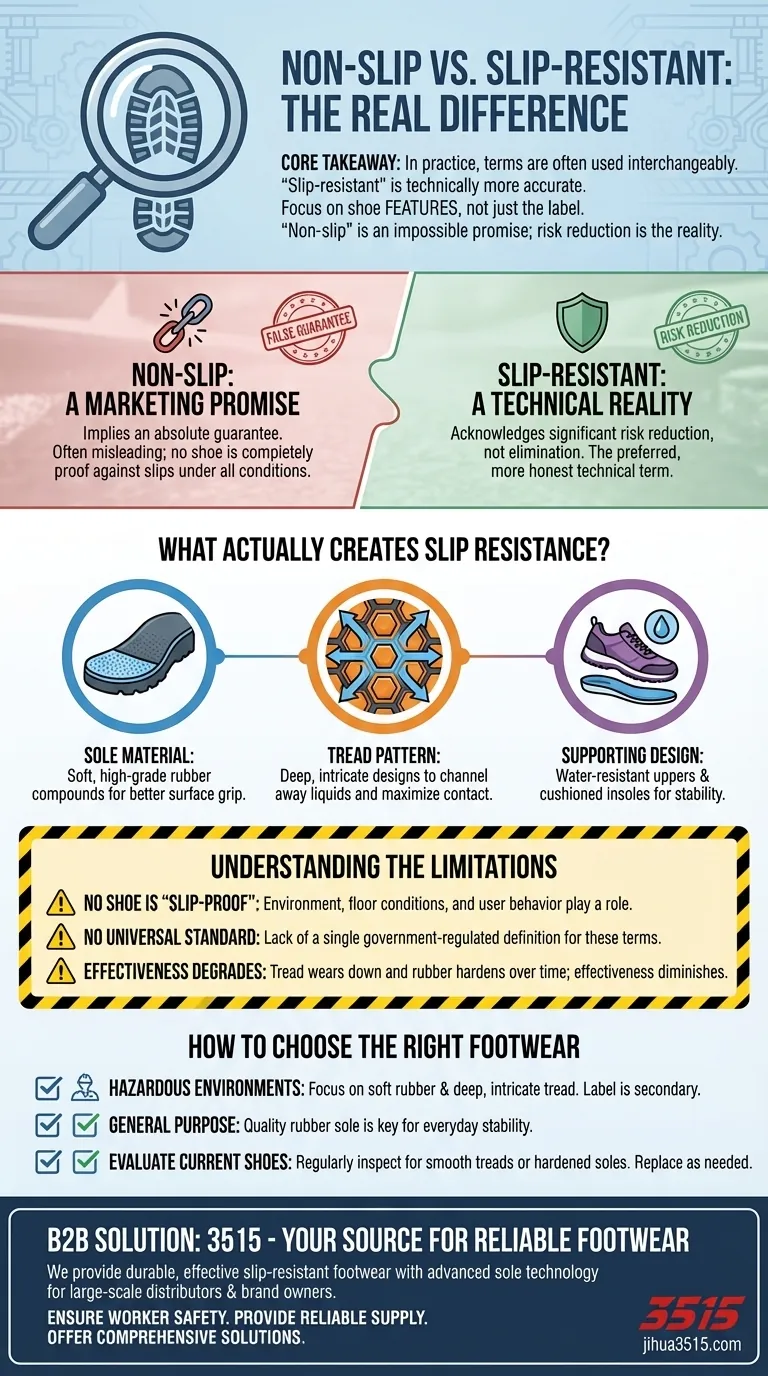

Core Takeaway: Honestly, the terms are pretty much used interchangeably in the industry, even though "slip-resistant" is the more technically accurate term. The real difference lies in the shoe's features, not the label. "Non-slip" is an impossible promise. Risk reduction is the name of the game.

Now, let's break this down.

Deconstructing the Terminology

The problem is, "non-slip" is marketing hyperbole. It implies a guarantee that just doesn't exist, no matter how good the shoe. "Slip-resistant" is the preferred term used by safety professionals because it acknowledges that we're talking about reducing the risk of slips and falls, not eliminating them entirely.

What Actually Makes a Shoe Slip-Resistant?

Forget the labels; what really matters?

- The Sole Material: Look for high-grade or synthetic rubber. Soft, grippy rubber is your best bet for maximizing traction.

- The Tread Pattern: Deep, intricate treads and hexagonal patterns are designed to channel away liquids like water and oil, increasing the contact surface area and grip.

- Beyond the Sole: Consider water-resistant uppers and cushioned insoles for added safety and stability.

Understanding the Trade-offs and Limitations

But hold on. No shoe is a magic bullet.

- No Shoe is "Slip-Proof": Even the best shoes can't completely eliminate the risk of a slip, especially with factors like floor conditions and user behavior.

- Lack of a Universal Standard: There's no single, regulated definition of "slip-resistant." You need to rely on your own judgment and critical thinking, not just a label.

- Wear and Tear Diminishes Effectiveness: Over time, the tread will wear down, and the rubber might harden. Regularly inspect your shoes and replace them when necessary.

How to Choose the Right Footwear

Here's a quick checklist:

- Maximum Safety in Hazardous Environments: Focus on shoes with soft, high-grade rubber soles and deep, intricate treads. The "non-slip" vs. "slip-resistant" label is secondary.

- General Purpose with Added Security: A slightly less aggressive tread might be fine, but a quality rubber sole is still key.

- Evaluating Your Current Shoes: Regularly check for worn-down treads or hardened soles. Replace them when the grip diminishes.

Ultimately, your goal is to make an informed decision based on the shoe's function, not just flashy marketing. In practice, there is no functional difference. The terms "non-slip" and "slip-resistant" are used interchangeably by manufacturers and marketers to describe footwear designed to reduce the risk of slipping. However, the term slip-resistant is more accurate and is preferred by safety professionals, as no shoe can completely eliminate the possibility of a slip.

The core issue is not the label on the box, but the technology in the sole. Instead of getting caught up in the "non-slip" vs. "slip-resistant" debate, your focus should be on the specific features—like sole material and tread design—that actually provide grip.

Deconstructing the Terminology

The confusion between these terms stems from a conflict between marketing language and physical reality. Understanding this distinction is the first step toward making an informed choice.

"Non-Slip": A Marketing Promise

The term non-slip suggests an absolute guarantee—that a shoe will prevent slips under any condition. This is an impossible claim.

Because this term implies a level of safety that cannot be delivered, it is best viewed as a marketing descriptor rather than a technical specification.

"Slip-Resistant": A Technical Reality

Slip-resistant is the more precise and honest term. It acknowledges that while the footwear is engineered to significantly reduce the likelihood of slipping, it cannot eliminate the risk entirely.

This is the term you will see used by scientific and consumer protection organizations because it accurately frames the shoe's purpose: risk minimization, not risk elimination.

What Actually Creates Slip Resistance?

Since the label itself isn't a reliable guide, you must evaluate the shoe's physical characteristics. True slip resistance comes from the engineering of the outsole.

The Role of Sole Material

The material of the outsole is the foundation of its grip. Look for shoes made with high-grade, soft rubber compounds.

Softer rubber creates more friction against a surface, allowing it to conform better to microscopic imperfections in the flooring and maintain a stronger hold, especially on wet or greasy surfaces.

The Importance of Tread Pattern

The design of the tread is engineered to manage contaminants like water and oil. Effective slip-resistant shoes feature small, intricate tread patterns, often in hexagonal or circular shapes.

These patterns work by channeling liquids away from the point of contact between the sole and the floor. This maximizes the surface area of the rubber touching the ground, which is essential for maintaining traction.

Supporting Design Features

While the outsole does the heavy lifting, other features contribute to overall stability.

A water-resistant upper keeps the foot dry and secure, while a cushioned insole and a slightly wider toe box provide a stable base, preventing your foot from shifting inside the shoe.

Understanding the Limitations

Even the best-designed shoe is a tool, not a magic solution. Acknowledging the limitations is crucial for maintaining safety.

No Shoe is "Slip-Proof"

It must be repeated: no shoe can prevent 100% of slips. The type and amount of contaminant on the floor, the floor's surface material, and how a person walks all play a significant role. Slip-resistant shoes provide a powerful safety advantage, but they do not make you invincible.

The Lack of a Regulated Standard

A key source of confusion is that there is no single, government-regulated definition for "non-slip" or "slip-resistant" in consumer footwear. This is why you must learn to identify the physical features yourself rather than relying solely on the product's marketing claims.

Effectiveness Degrades Over Time

The effectiveness of a slip-resistant shoe is not permanent. As the soft rubber sole hardens with age and the tread pattern wears down, the shoe's ability to grip and channel liquids diminishes significantly. Worn-out safety shoes are no longer safe.

How to Choose the Right Footwear

Your final choice should be guided by your specific environment and safety needs.

- If your primary focus is maximum safety in hazardous environments (e.g., commercial kitchens, hospitals): Ignore the marketing terms and inspect the outsole for soft rubber and a deep, intricate tread pattern designed to channel liquids.

- If your primary focus is general stability for everyday use (e.g., walking on rainy sidewalks): A shoe with a quality rubber sole will suffice, even if the tread pattern is less aggressive.

- If you are evaluating your current shoes: Check the tread depth and press on the sole. If the treads are smooth or the rubber feels hard and inflexible, it's time for a replacement.

Ultimately, empowering yourself with knowledge of what makes a shoe effective is the only reliable way to ensure your safety.

Summary Table:

| Feature | Non-Slip (Marketing Term) | Slip-Resistant (Technical Term) |

|---|---|---|

| Meaning | Implies an absolute guarantee | Acknowledges risk reduction |

| Accuracy | Misleading, no shoe is slip-proof | More precise and honest |

| Focus | Marketing promise | Engineering and safety reality |

Need High-Quality, Reliable Slip-Resistant Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear designed for real-world hazards. We provide durable, effective slip-resistant shoes and boots with the advanced sole technology discussed in this article.

We help distributors, brand owners, and bulk clients by:

- Ensuring Worker Safety: Our footwear is engineered with high-grade rubber and effective tread patterns to minimize slip risks.

- Providing Reliable Supply: As a major manufacturer, we guarantee consistent quality and volume for your business needs.

- Offering Comprehensive Solutions: Our production capabilities encompass all types of safety shoes and boots for various industries.

Protect your team and your business with footwear you can trust. Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health