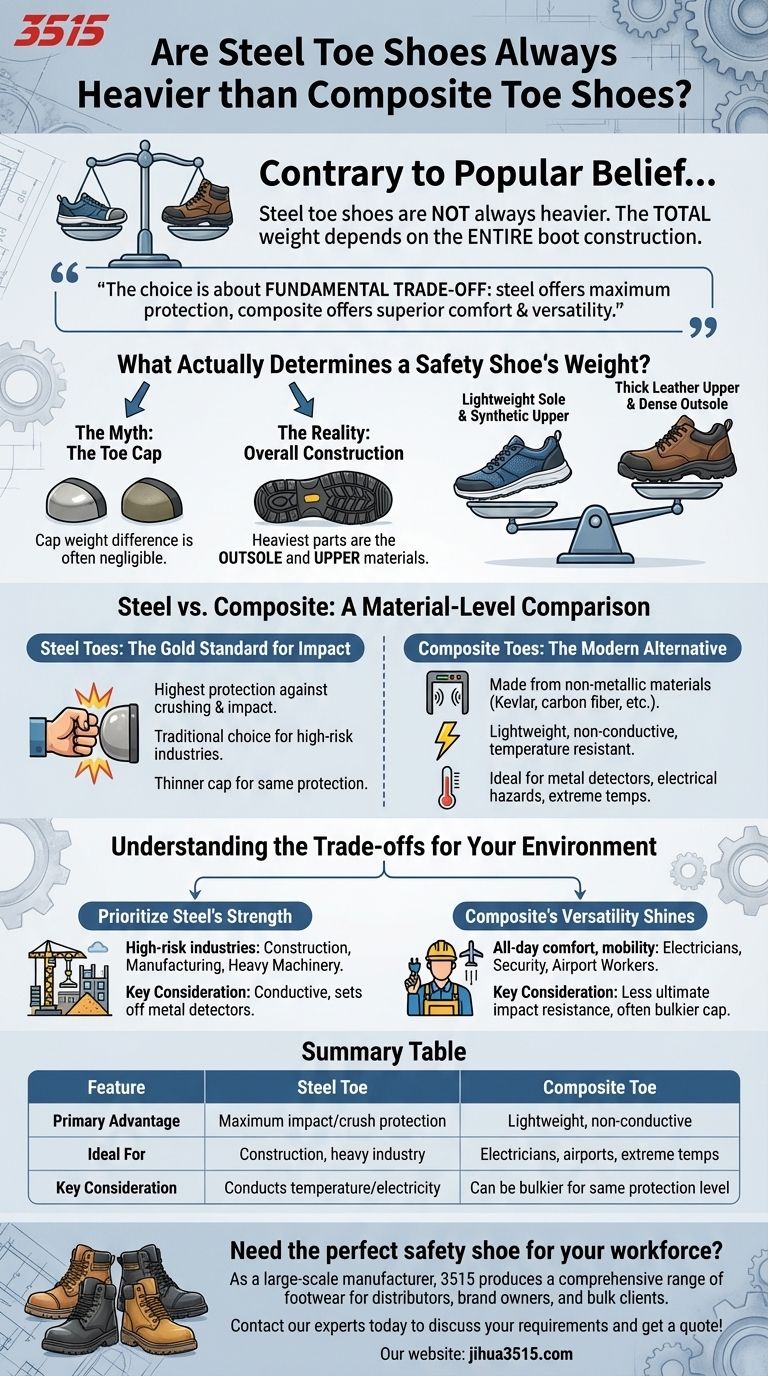

Contrary to popular belief, steel toe shoes are not always heavier than composite toe shoes. The total weight of a safety shoe is determined by the construction of the entire boot—including the sole, upper materials, and other features—not just the protective toe cap itself. A well-designed steel toe shoe can easily be lighter than a bulky composite toe shoe.

The choice between steel and composite toes is not about finding the lightest option, but about understanding the fundamental trade-off: steel offers maximum impact protection, while composite offers superior comfort and versatility for specific environments.

What Actually Determines a Safety Shoe's Weight?

Most people incorrectly assume the toe cap is the primary driver of a shoe's weight. The reality is that overall design and materials play a much larger role.

The Myth of the Toe Cap

The protective toe cap, whether steel or composite, represents only a small fraction of the shoe's total weight.

While steel is denser than composite materials, the difference in the cap alone is often negligible when considering the entire shoe.

The Role of Overall Construction

The heaviest parts of a work boot are typically the outsole and the upper materials. A thick, rugged rubber sole or a heavy-duty leather upper will add far more weight than the choice of toe cap.

Therefore, a steel toe shoe with a lightweight sole and synthetic upper could easily be lighter than a composite toe shoe built with thick leather and a dense outsole.

Steel vs. Composite: A Material-Level Comparison

The real difference between the two materials lies in their core properties and how they perform under specific conditions.

Steel Toes: The Gold Standard for Impact

Steel toes offer the highest available level of protection against crushing (compression) and impact hazards. They are the traditional choice for high-risk industries.

Because steel is so strong, the toe cap can be made thinner than a composite cap while still meeting safety standards, which can sometimes reduce its bulk.

Composite Toes: The Modern Alternative

Composite toes are made from non-metallic materials like Kevlar, carbon fiber, fiberglass, or plastic. Their primary advantage is that they are lightweight and do not conduct electricity or heat.

This makes them an excellent choice for professionals who must pass through metal detectors or work in environments with electrical hazards or extreme temperatures.

Understanding the Trade-offs for Your Environment

Choosing the right safety toe requires you to match the material's properties to the specific risks and demands of your workplace.

When to Prioritize Steel's Strength

Steel toes are the preferred choice in high-risk industries like construction, manufacturing, and heavy machinery operation.

The key trade-off is that steel is conductive and will set off metal detectors. This can be a significant inconvenience in certain jobs.

When Composite's Versatility Shines

Composite toes are ideal for roles where all-day comfort and mobility are critical, such as for electricians, security guards, or airport workers.

Their primary limitation is that they generally offer less ultimate impact resistance than steel, and composite caps must be bulkier to provide the same level of protection.

Environmental Factors: Temperature and Electricity

Because composite materials do not transfer temperature easily, they are far more comfortable in both very hot and very cold climates.

This non-conductive property is also a critical safety feature for anyone working with or around live electrical circuits.

Making the Right Choice for Your Goal

Select your safety shoe based on the primary demands of your job, not on a single factor like weight.

- If your primary focus is maximum impact protection: Choose steel toes for their unparalleled strength in high-risk industrial environments.

- If your primary focus is all-day comfort and mobility: Choose composite toes to reduce fatigue, especially if you walk several miles per day.

- If your primary focus is a specialized environment: Choose composite toes if you work around metal detectors, electrical hazards, or in extreme temperatures.

Ultimately, the best safety shoe is the one that provides the right protection for your specific task.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Primary Advantage | Maximum impact/crush protection | Lightweight, non-conductive |

| Ideal For | Construction, heavy industry | Electricians, airports, extreme temps |

| Key Consideration | Conducts temperature/electricity | Can be bulkier for same protection level |

Need the perfect safety shoe for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether your priority is the maximum protection of steel toes or the versatile comfort of composite toes, our production capabilities encompass all types of safety shoes and boots tailored to your specific industry needs.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is the myth about steel-toe boots, and is it true? Debunking the Amputation Risk

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection

- How does composite toe compare to steel toe? Choose the Right Safety for Your Job

- In which work environments are steel toe shoes particularly necessary? Essential for Construction, Warehousing & More

- What industries are safety toe work boots best suited for? Protect Your Feet in High-Risk Environments

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- What are key tips for fitting steel toe boots correctly? Ensure Safety and All-Day Comfort

- What are the benefits of wearing proper work socks with steel toe boots? Boost Comfort & Safety