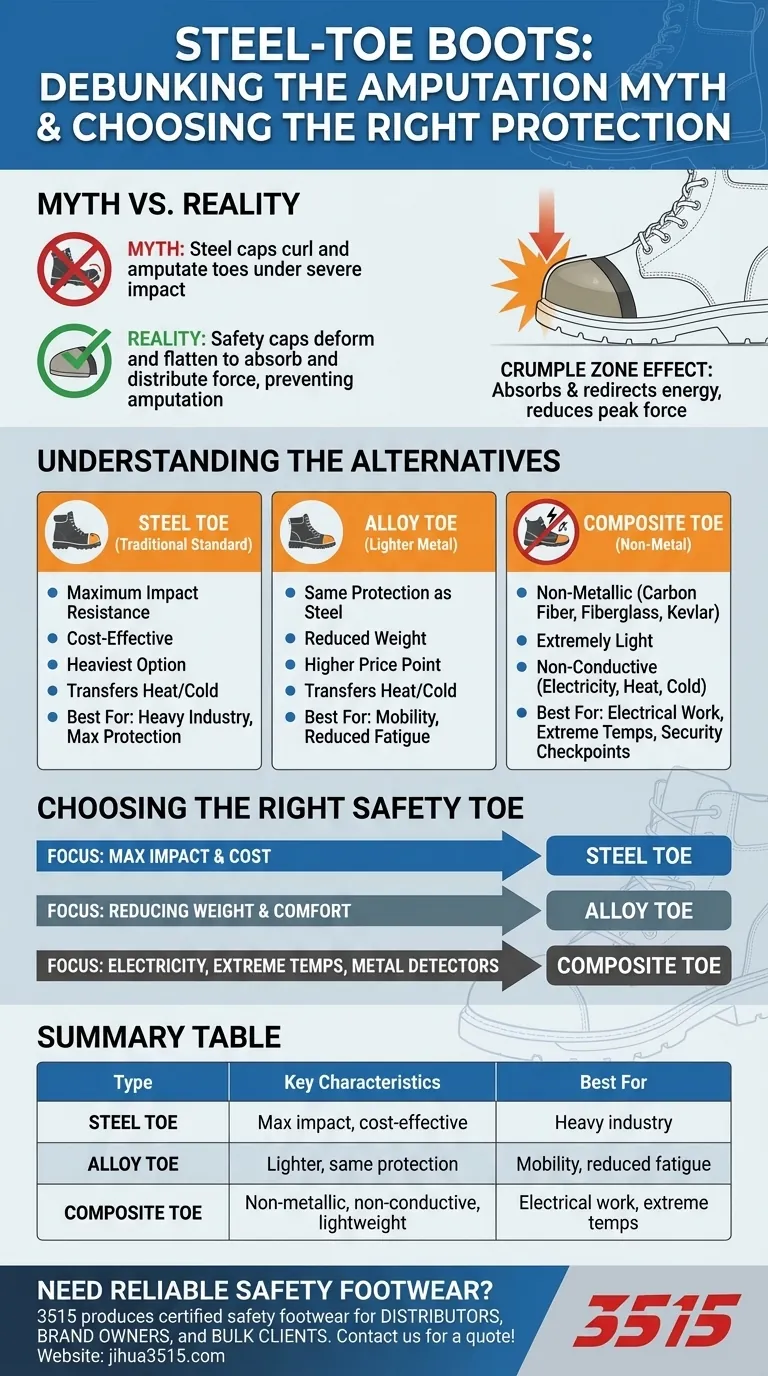

The enduring myth about steel-toe boots is that a severe impact can cause the protective cap to curl inwards and amputate your toes. This belief is unequivocally false. Safety footwear is engineered with the precise goal of preventing such a failure; the steel cap is designed to deform and flatten under extreme, catastrophic force, not to create a cutting hazard.

The core truth is that safety toe caps—whether steel, alloy, or composite—are designed to absorb and distribute impact. Under forces that exceed their design limits, they will flatten to protect the foot from the initial crushing blow, a mechanism that prevents the amputation scenario feared in the myth.

Deconstructing the Amputation Myth

How Steel Caps Actually Behave Under Stress

The idea of a steel cap curling into a blade is a fundamental misunderstanding of its design. The cap is a dome structure, one of the strongest shapes for resisting compressive force.

When an impact or compression force exceeds the boot's safety rating, the steel will begin to deform. However, it is engineered to bend and flatten outwards and downwards, increasing the surface area over the toes to distribute the load.

This action effectively creates a space, however small, to shield the toes from the full, direct force of the impact. While a severe crush injury is still possible in a catastrophic event, it is a far more survivable outcome than amputation.

The Physics of Impact Absorption

Think of a safety toe cap like the crumple zone on a car. Its primary job is to absorb and redirect energy during a collision.

The cap is designed to fail predictably and safely. By deforming, it absorbs a significant amount of the impact energy, slowing the object and reducing the peak force transferred to your foot.

Understanding the Alternatives to Steel

While steel is the traditional standard, modern safety boots offer other materials, each with a distinct profile.

Alloy Toe: Lighter Metal Protection

Alloy toes are typically made from lightweight materials like aluminum or titanium. They provide the same level of impact and compression resistance as steel.

The main advantage is a significant reduction in weight, which can decrease fatigue. However, this often comes at a higher price point.

Composite Toe: The Non-Metal Option

Composite toes are crafted from non-metal materials such as carbon fiber, fiberglass, or Kevlar. They are extremely light and have a key advantage: they do not conduct heat, cold, or electricity.

This makes them the superior choice for electricians or those working in extreme temperature environments. While they meet the same safety standards, some believe they may offer slightly less ultimate protection than metal caps under extreme, beyond-spec forces.

Understanding the Trade-offs

Choosing the right safety toe is not about finding the "best" one, but the right one for your specific environment and needs. There is no single perfect solution.

Protection vs. Weight

Steel provides maximum, time-tested protection but is the heaviest option. Alloy offers comparable protection at a reduced weight, while composite is the lightest of all.

For jobs requiring constant walking or movement, the weight savings from alloy or composite can be a significant factor in all-day comfort and reducing fatigue.

Environmental Factors

If you frequently pass through metal detectors or work near live electrical circuits, a composite toe is the only practical choice. Its non-conductive properties are a critical safety feature in these scenarios.

Likewise, in extreme cold or heat, a composite toe will not transfer thermal energy to your foot the way a metal cap will.

How to Choose the Right Safety Toe for Your Needs

Base your decision on the most common risks and requirements of your job.

- If your primary focus is maximum impact resistance and cost-effectiveness: A traditional steel toe remains the proven industry standard.

- If your primary focus is reducing footwear weight for comfort and mobility: An alloy toe provides steel-level protection in a lighter package.

- If your primary focus is working with electricity, in extreme temperatures, or passing through metal detectors: A composite toe is the safest and most logical choice.

Ultimately, understanding how a safety toe is engineered to protect you is the first step in selecting the right tool for the job.

Summary Table:

| Safety Toe Type | Key Characteristics | Best For |

|---|---|---|

| Steel Toe | Maximum impact resistance, cost-effective | Heavy industry, maximum protection needs |

| Alloy Toe | Lighter weight, same protection as steel | Jobs requiring mobility and reduced fatigue |

| Composite Toe | Non-metallic, non-conductive, lightweight | Electrical work, extreme temperatures, security checkpoints |

Need Reliable Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered to meet the highest standards of protection and comfort.

We can help you equip your workforce with the right safety solution. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How do composite toe boots compare to steel toe boots? A Guide to Maximum Safety & Comfort

- How much weight can steel toe boots typically withstand? 2,500 lbs of Crush Protection Explained

- Is it true that steel toe boots make your toes colder? The Truth About Cold-Weather Work Boots

- Why is it necessary to conduct mechanical strength evaluations on polycarbonate toecaps? Ensure Impact Safety & Comfort

- What types of steel are used in steel toe caps? Choose the Right Protection for Your Worksite

- How does the weight of steel-toe boots compare to composite-toe boots? Uncover the Real Trade-Offs

- How does composite toe compare to steel toe? Choose the Right Safety for Your Job

- Is there any truth to the myth about steel toe boots causing toe injuries upon impact? Debunking Common Safety Concerns