Ultimately, safety toe work boots are essential for any job where your feet are at risk from impact or compression. They are most commonly required in industries like construction, warehouse and distribution, manufacturing, maintenance, and farming or ranching due to the daily presence of heavy objects and machinery.

The decision to wear a safety toe boot is not about the industry title, but about a realistic assessment of the hazards present in your specific work environment. If there's a risk of something heavy falling on or rolling over your foot, a safety toe is a fundamental requirement.

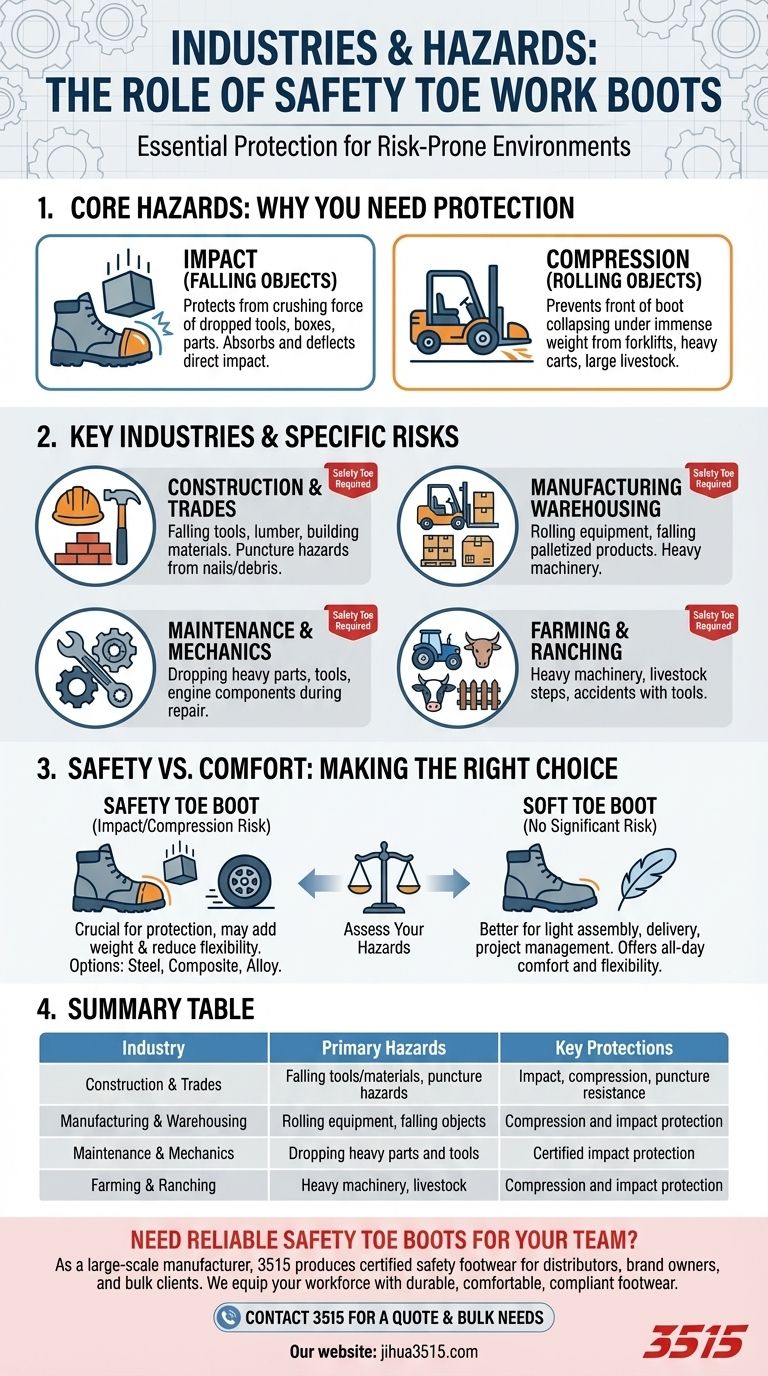

The Core Hazards That Demand a Safety Toe

Understanding why certain industries require safety toe boots is more important than simply listing them. The need is dictated by the presence of two primary, non-negotiable risks.

Hazard 1: Impact from Falling Objects

This is the most common reason for a safety toe. It protects your toes from being crushed by the force of something heavy falling from above.

Think of dropped tools on a construction site, a box falling from a high shelf in a warehouse, or a heavy part slipping during maintenance. The hardened cap in the boot is designed to absorb and deflect this direct impact.

Hazard 2: Compression from Rolling Objects

This hazard involves objects that can roll over or press down on the foot. The structural integrity of the safety toe prevents the front of the boot from collapsing under immense weight.

This is a critical risk in environments with forklifts, pallet jacks, heavy carts, or even large livestock. Manufacturing floors and distribution centers are prime examples where this type of protection is vital.

A Deeper Look at Key Industries

While the hazards are universal, they manifest differently across various fields. Here’s how these risks apply to the most common industries.

Construction and Trades

Workers in construction, plumbing, and electrical trades face constant impact risks from falling tools, lumber, pipes, and other building materials. The rugged and often unpredictable terrain also means a higher chance of puncture hazards from nails and debris.

Manufacturing and Warehousing

These environments are defined by heavy machinery and the movement of goods. The primary dangers are compression from forklifts and other vehicles, as well as impacts from heavy, palletized products that could fall or shift during handling.

Maintenance and Mechanics

Working on heavy equipment, vehicles, or industrial machinery means handling dense, heavy parts. A dropped engine component or a large wrench can cause severe injury, making impact protection an absolute necessity.

Farming and Ranching

This industry combines risks from both heavy machinery like tractors and the unpredictable nature of large animals. A safety toe protects against being stepped on by livestock and against accidents involving heavy equipment and tools.

Understanding the Trade-offs: Safety vs. Comfort

While crucial for protection, safety toe boots are not the right choice for every job. Mandating them where they aren't needed can lead to unnecessary discomfort and fatigue.

When a Safety Toe Is Overkill

If your job involves no significant risk of impact or compression, a soft-toe boot is often a better choice. Roles like light assembly, some delivery services, or project management on a site with no active hazards may not require a safety toe.

The Comfort and Weight Factor

Safety toe caps, particularly traditional steel toes, add weight and rigidity to a boot. This can reduce flexibility and lead to more fatigue over a long day.

Modern alternatives like composite toes (non-metallic) and alloy toes (lighter metals) offer certified protection with less weight, mitigating some of these trade-offs.

Making the Right Choice for Your Job

Your choice should be based on a clear-eyed assessment of your daily tasks and environment.

- If you work around heavy, mobile equipment or stacked materials: A safety toe is non-negotiable to protect against high-risk impact and compression events.

- If your primary hazard is dropping tools or building materials: Focus on certified impact protection, making a safety toe an essential part of your personal protective equipment (PPE).

- If your environment is unpredictable with mixed hazards: A safety toe provides a critical baseline of protection against unforeseen accidents.

- If your daily tasks have no risk of falling or rolling objects: You can prioritize a more flexible and lightweight soft-toe boot for all-day comfort.

Ultimately, evaluating the real-world risks of your job is the only way to ensure you have the right level of protection.

Summary Table:

| Industry | Primary Hazards | Key Protections |

|---|---|---|

| Construction & Trades | Falling tools/materials, puncture hazards | Impact, compression, and puncture resistance |

| Manufacturing & Warehousing | Rolling equipment (forklifts), falling objects | Compression and impact protection |

| Maintenance & Mechanics | Dropping heavy parts and tools | Certified impact protection |

| Farming & Ranching | Heavy machinery, livestock | Compression and impact protection |

Need reliable safety toe boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety toe shoes and boots, designed to meet the rigorous demands of your industry.

We can help you equip your workforce with durable, comfortable, and compliant footwear that reduces workplace injuries.

Contact 3515 today for a quote and discover how our manufacturing expertise can meet your bulk footwear needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the advantages of steel toe caps? Unmatched Impact & Puncture Protection

- What are the benefits of wearing steel toe boots? Maximum Impact Protection & Durability

- What types of workplaces are steel toe boots traditionally used in? Essential Foot Protection for Hazardous Jobs

- Do steel toe boots lack style options? Discover Modern, Stylish Safety Footwear

- What are the impact and compression requirements for safety toe boots? Essential Standards for Worker Protection

- What are the advantages of steel toe protection in work boots? Unmatched Safety & Durability

- When should steel toe boots be replaced? Protect Your Feet from Costly Workplace Injuries

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.